Method for preventing settling and cracking of terrace with large area by utilizing combined prestressing concrete beams at region with soft soil layer

A soft soil layer, prestressed technology, applied in the field of combined prestressed concrete beams to prevent large-scale floor settlement and cracking, can solve the problems of buildings or workshops not being used normally, uneven settlement and cracking, and long construction period, etc. Achieve the effect of low cost, short construction period and prevention of settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

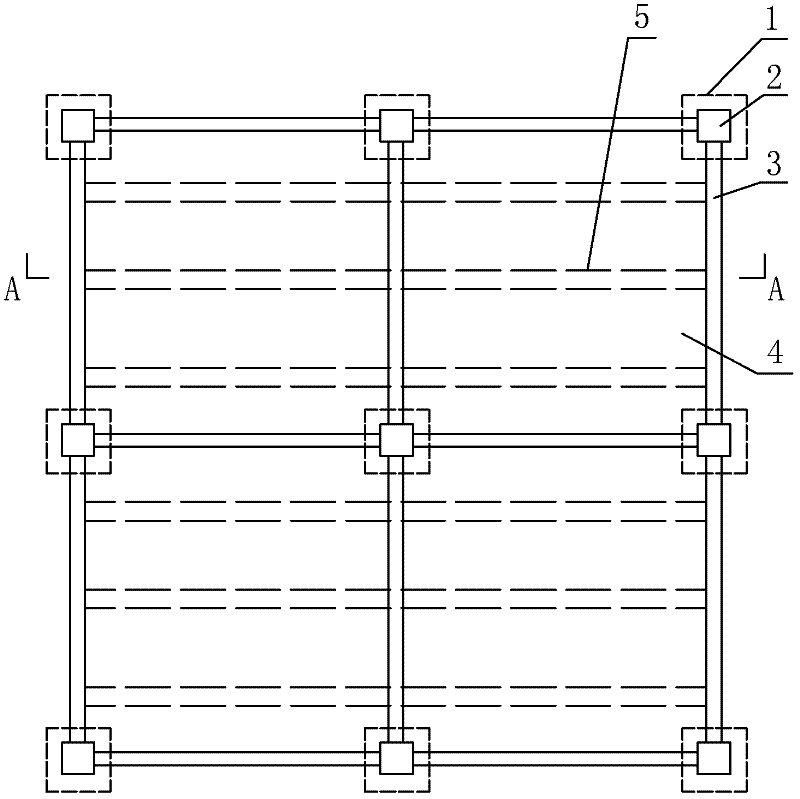

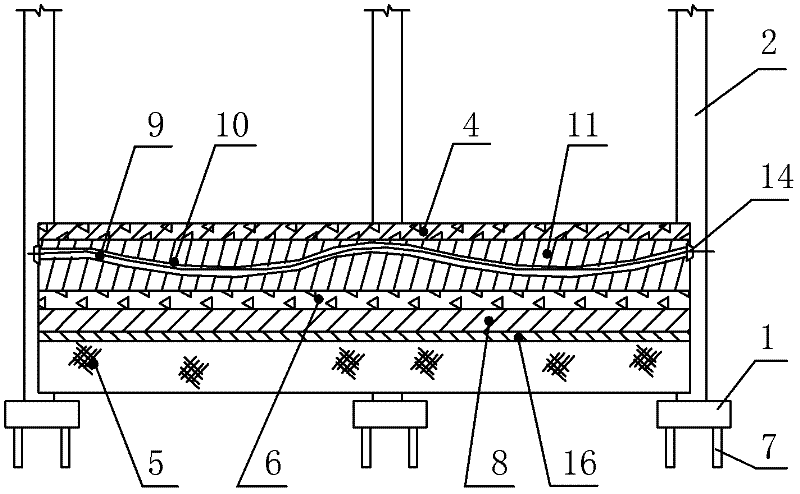

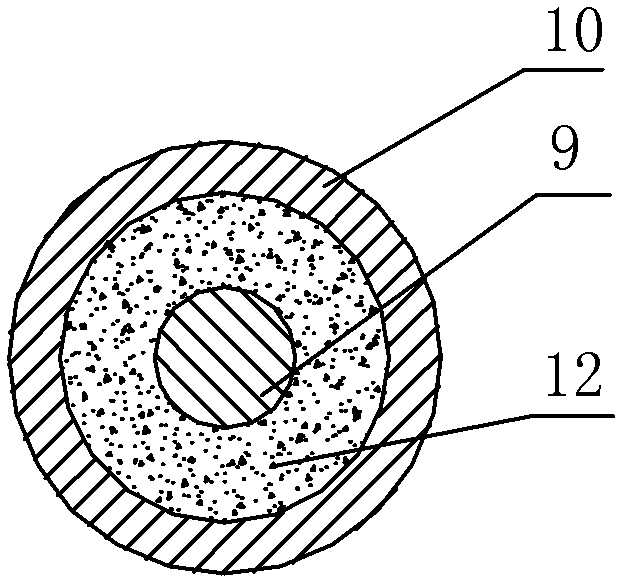

[0045] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the method of using combined prestressed concrete beams to prevent large-scale floor settlement and cracking in areas with weak soil layers includes the following steps:

[0046] 1) According to the distribution of the span, a tamped strip-shaped plain soil zone 5 is set on the soft soil layer under the designed reinforced concrete floor, and the distance between the adjacent strip-shaped plain soil zone and the strip-shaped plain soil zone is 2 ~5m, the width of the strip-shaped plain soil belt is 10-50cm, and the thickness of the strip-shaped plain soil belt is 10-50cm; the material of the strip-shaped plain soil belt 5 is clay;

[0047] 2) Arranging a strip geotextile or a strip geogrid 16 on the strip plain soil belt 5;

[0048] 3) On the belt-shaped geotextile or belt-shaped geogrid 16, a belt-shaped crushed stone cushion or a belt-shaped sandstone cushion or a belt-shaped cement stabilized sand layer ...

Embodiment 2

[0063] like Figure 5 As shown, it is basically the same as that of Example 1, the difference is that all the belt-shaped plain soil belts form a grid-like structure, belt-shaped geotextiles or belt-shaped geogrids 16, belt-shaped gravel cushions or belt-shaped sand The arrangement of the stone cushion or the strip-shaped cement stabilized sand layer 8, the strip-shaped plain concrete cushion 6, and the prestressed concrete beam 11 is the same as that of the strip-shaped plain soil belt. Each of the prestressed concrete beams and the composite belt-shaped cushions below them are arranged vertically and horizontally with the intersecting prestressed concrete beams and the composite belt-shaped cushions below them to form a grid structure.

[0064] Experiments and implementation have proved that after adopting the method of this embodiment, there is no phenomenon of settlement or cracking on the large-area floors of buildings or workshops in areas with weak soil layers.

Embodiment 3

[0066] like Figure 6 , Figure 8 As shown, it is basically the same as Embodiment 1, except that the longitudinal section shape of the prestressed concrete beam 11 is a step-shaped unequal section with a wide top and a narrow bottom (the middle part of the square area surrounded by four pillars) The section height of the prestressed concrete beam is large, and the section height of the prestressed concrete beam near the ground beam area is small), which is conducive to the formation of the wave form of the bonded prestressed steel strand (slowly bonded prestressed steel strand) and the improvement of the prestressed steel strand. Stressed concrete beams have the ability to support the ground and the range of influence, while reducing costs; the strip-shaped plain concrete cushion 6, the strip-shaped crushed stone cushion or the strip-shaped sandstone cushion or the strip-shaped cement stabilized sand layer 8 It is stepped, which is conducive to the arrangement of bonded steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com