Structure and method of connecting I-type prestressed concrete beams using steel brackets

a technology of prestressed concrete and steel brackets, which is applied in the direction of bridges, bridge erection/assembly, bridge construction, etc., can solve the problems of imposing excessive construction costs on users, cracks around cold joints, and structural defects, etc., to achieve the effect of higher structural durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described in detail with reference to the attached drawings.

[0027] Reference now should be made to the drawings, in which the same reference numerals are used throughout the different drawings to designate the same or similar components.

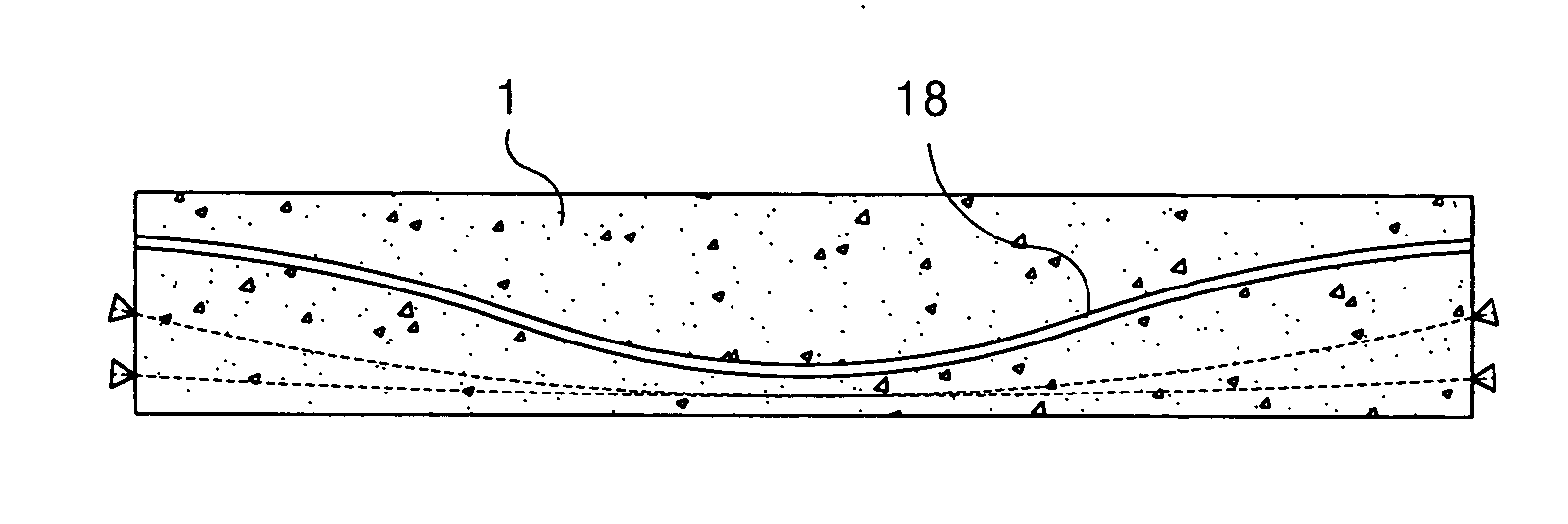

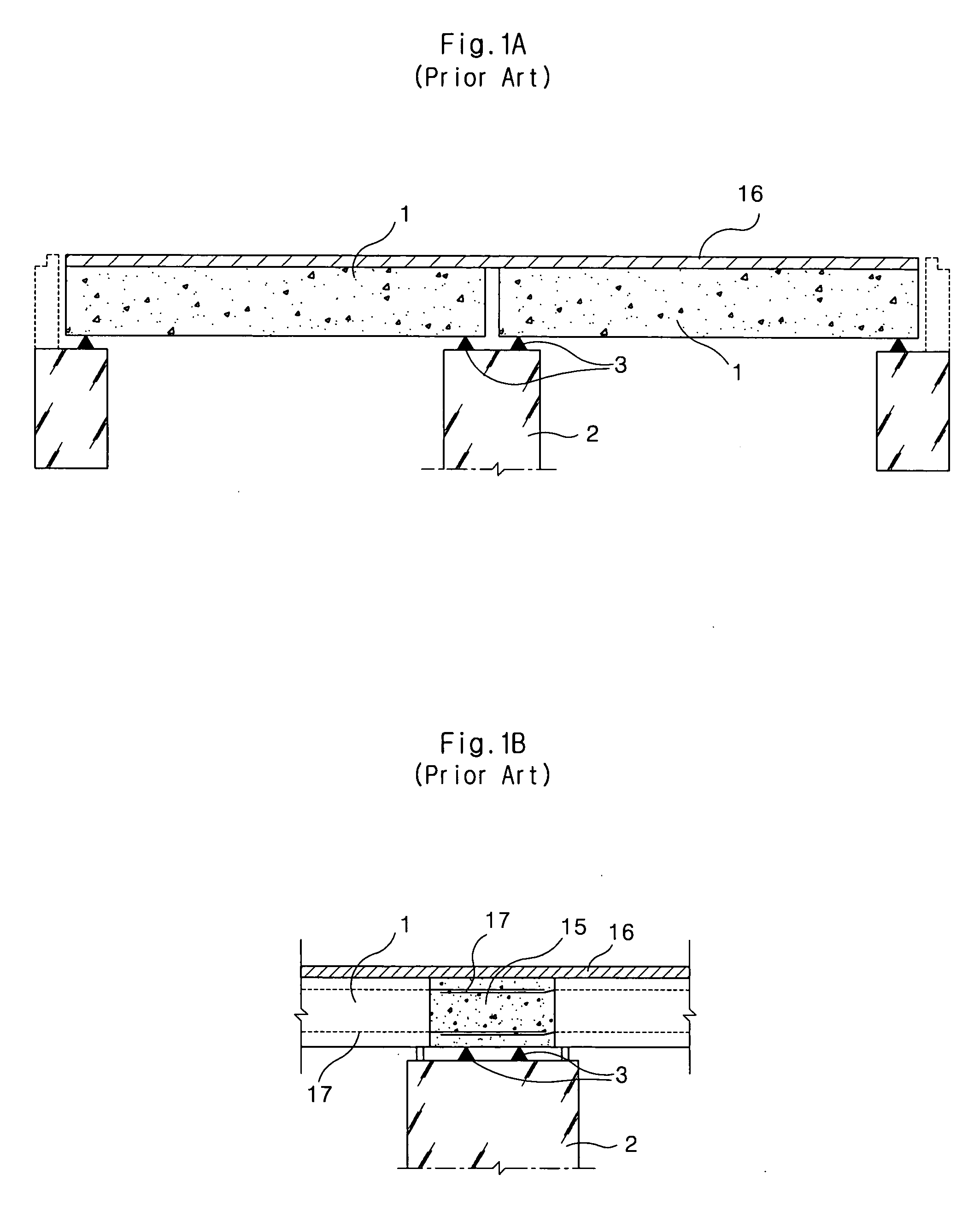

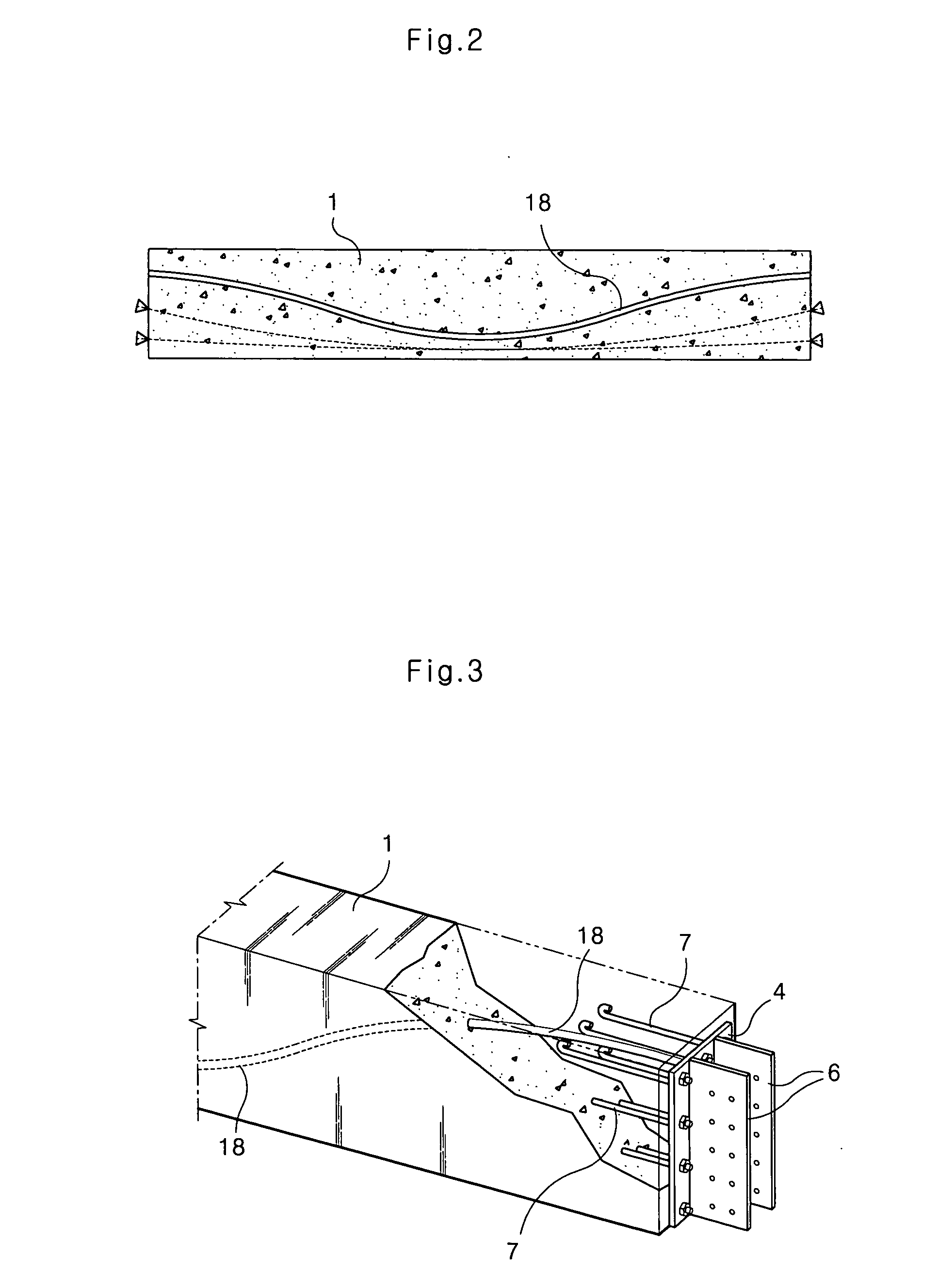

[0028]FIG. 2 is a sectional view of one of a plurality of I-type prestressed concrete beams 1 (PSC-I beams) connected to each other with a structure for connecting the plurality of PSC-I beams, according to an embodiment of the present invention. FIG. 3 is a partially broken perspective view of the PSC-I beam 1 of FIG. 2, in which a part around an end of the PSC-I beam 1 is shown. As shown in FIGS. 2 and 3, in the beam connecting structure according to the present invention, each of the PSC-I beams, made of concrete, has a sheath pipe 18 therein. That is, when the PSC-I beam 1 is produced, the sheath pipe 18 is previously embedded in the concrete. The sheath pipe 18 receives therein a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com