Post-tensioned prestressed concrete beam duct grouting material of highway bridge and preparation method thereof

A grouting technology for concrete beams and tunnels, which is applied in the field of cement-based materials and can solve problems such as failure to meet standard requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

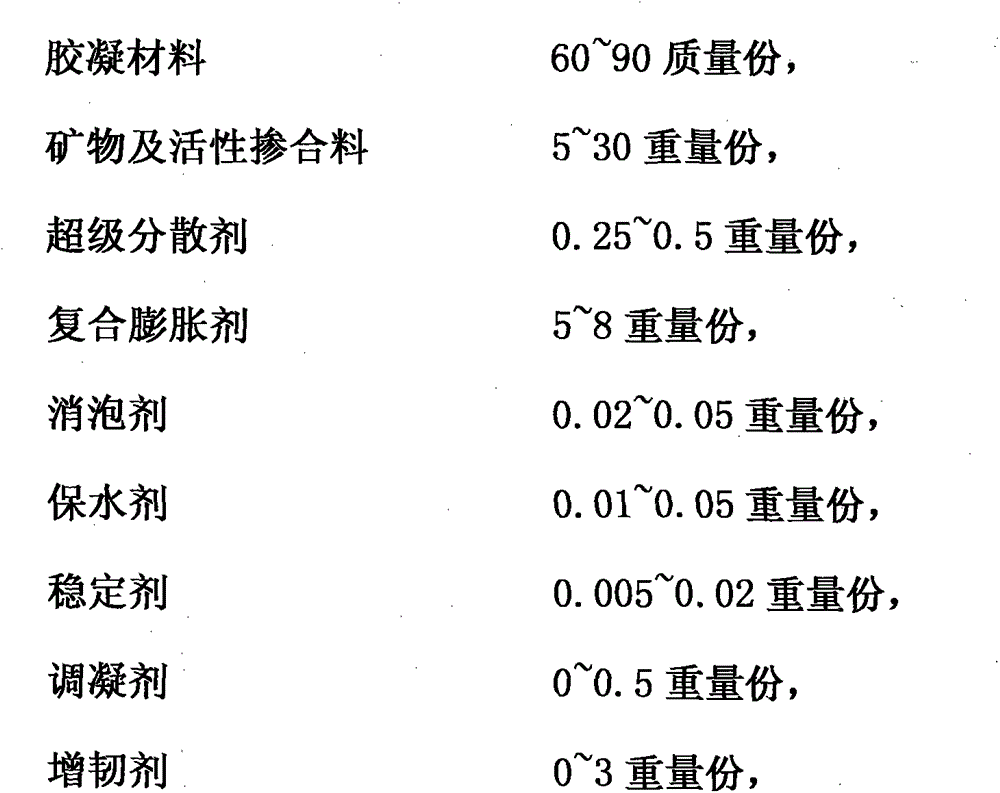

Method used

Image

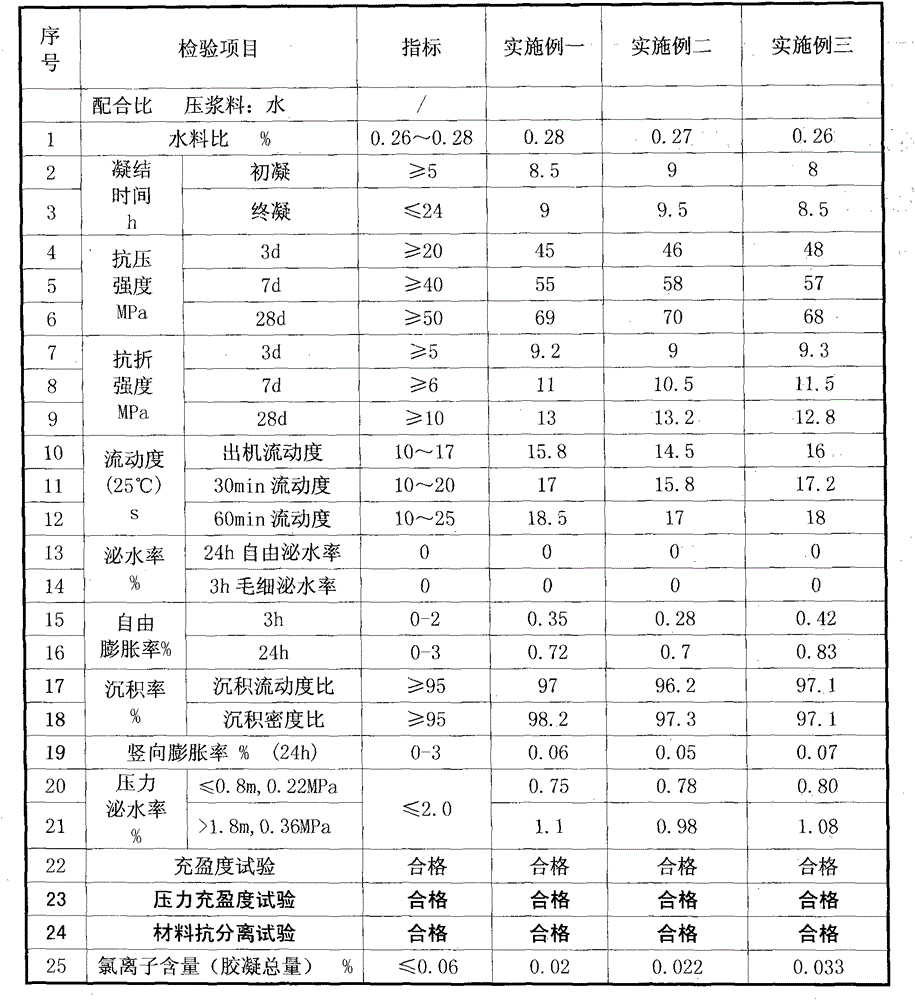

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment:

[0023] Example 1: Conch PO4 2.5 cement 80, ultrafine beads 3, silica fume 1.2, mineral powder 2, limestone powder 2.5, super dispersant 0.29, composite expansion agent 6, carboxymethyl cellulose 0.015, xanthan gum 0.01, Magnesium aluminum silicate 0.03, redispersible latex powder 1, steel rust inhibitor 1.

[0024] Example 2: Conch P II 52.5 cement 70, superfine beads 2.5, mineral powder 12.5, silica fume 1, limestone powder 7.6, super dispersant 0.32, composite expansion agent 5.5, methyl hydroxyethyl cellulose ether 0.01, xanthan Glue 0.01, sodium alginate 0.02, organic bentonite 0.04, redispersible latex powder 0.5, steel rust inhibitor 1.

[0025] Example 3: Qianchao PO42.5 cement 82, ultrafine beads 4, mineral powder, 3.083, silica fume 1, limestone powder 1.5, super dispersant 0.35, composite expansion agent 6.5, carboxymethyl cellulose 0.015, xanthogen Glue 0.012, sodium pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com