Method and device for detecting mudjacking saturation of post-tensioned prestressed concrete beam pipe

A technology of concrete beams and detection methods, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., and can solve problems such as the influence of detection results, low work efficiency, and difficulty in analysis and judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

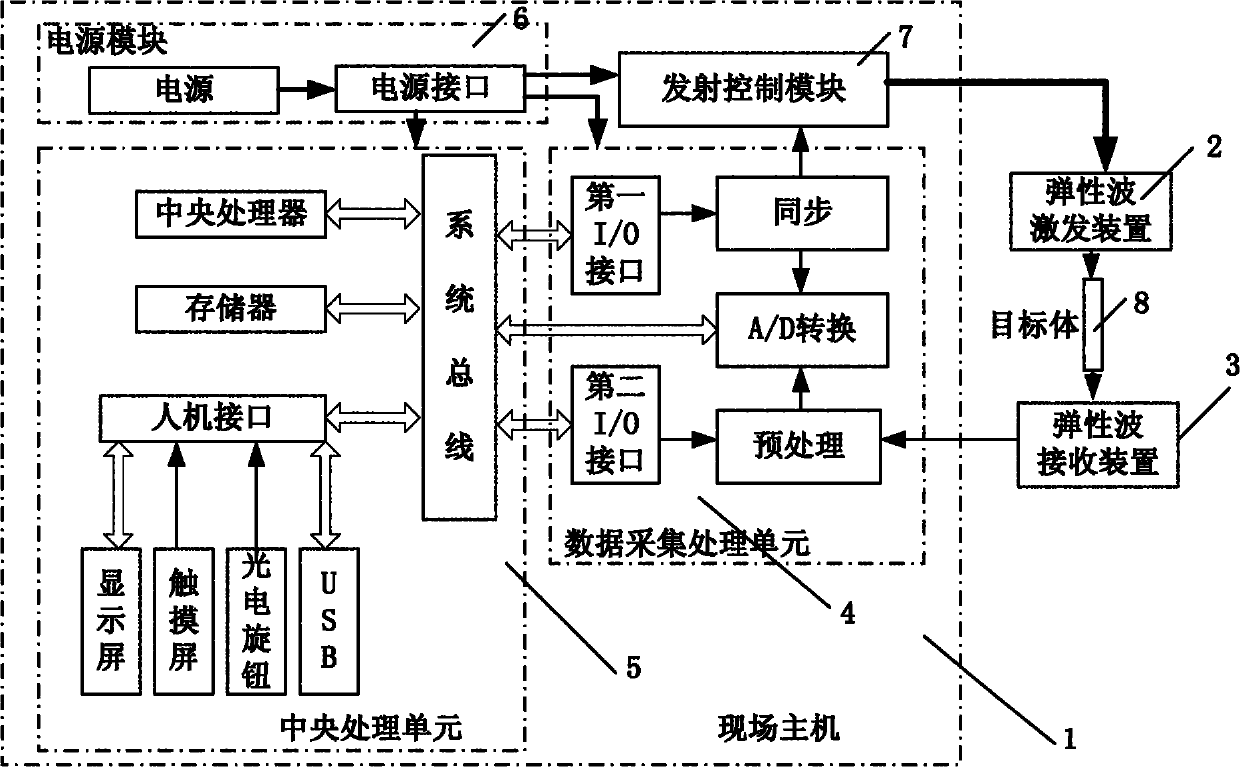

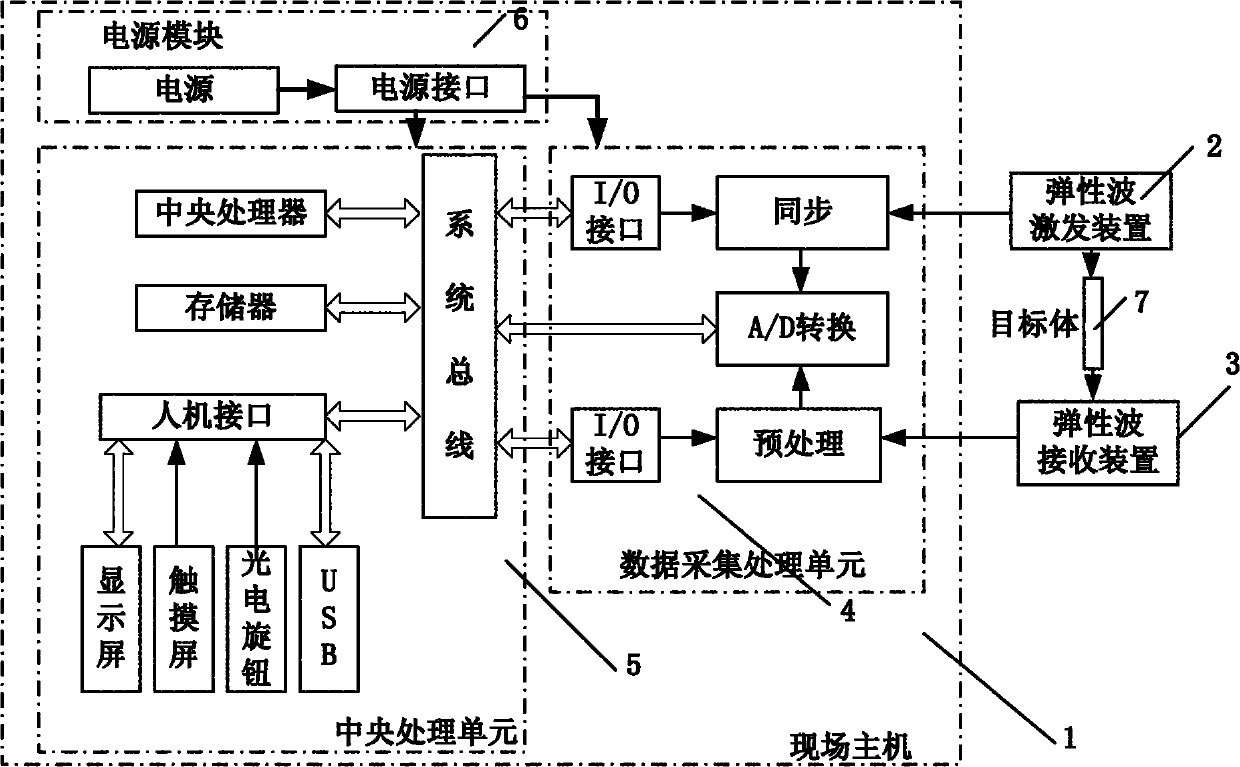

[0068] refer to figure 1 : A kind of hardware system of the device of the present invention:

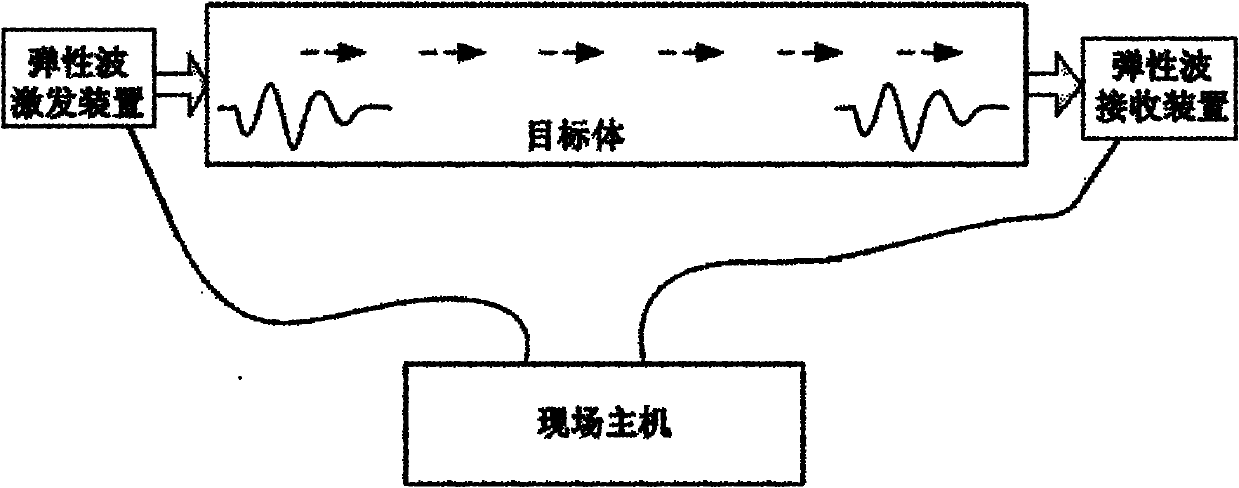

[0069] It includes a field host, an elastic wave excitation device and an elastic wave receiving device. The elastic wave excitation device and the elastic wave receiving device are respectively connected to the field host through cables; the field host includes a built-in data acquisition and processing module, a central processing unit, a power supply module, an elastic The wave emission control module; the elastic wave emission control module is connected with the elastic wave emission device. The data acquisition and processing module includes an interface circuit, a synchronization circuit, a signal preprocessing circuit and an A / D conversion module, wherein the first I / O interface circuit is connected to the synchronization circuit and the system bus, and the system bus is connected to the central processing unit; one output terminal of the synchronization circuit is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com