Steel plate-concrete composite structure reinforcement method of structural negative moment region

A technology of negative moment zone and composite structure, which is applied in the field of bridge and structural engineering in civil engineering, can solve the problems of affecting the size of the newly added prestress, limiting the bending bearing capacity, and the improvement of the rigidity of the FRP reinforced structure is not obvious, etc. To achieve the effect of enhancing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

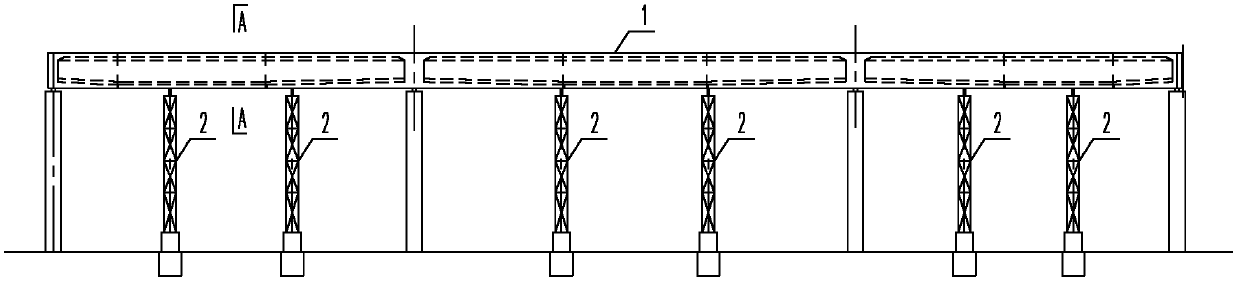

[0119] Embodiment 1 is a prestressed concrete continuous box girder bridge.

[0120] Novel steel plate-concrete composite structure reinforcement construction method according to the present invention comprises the following steps:

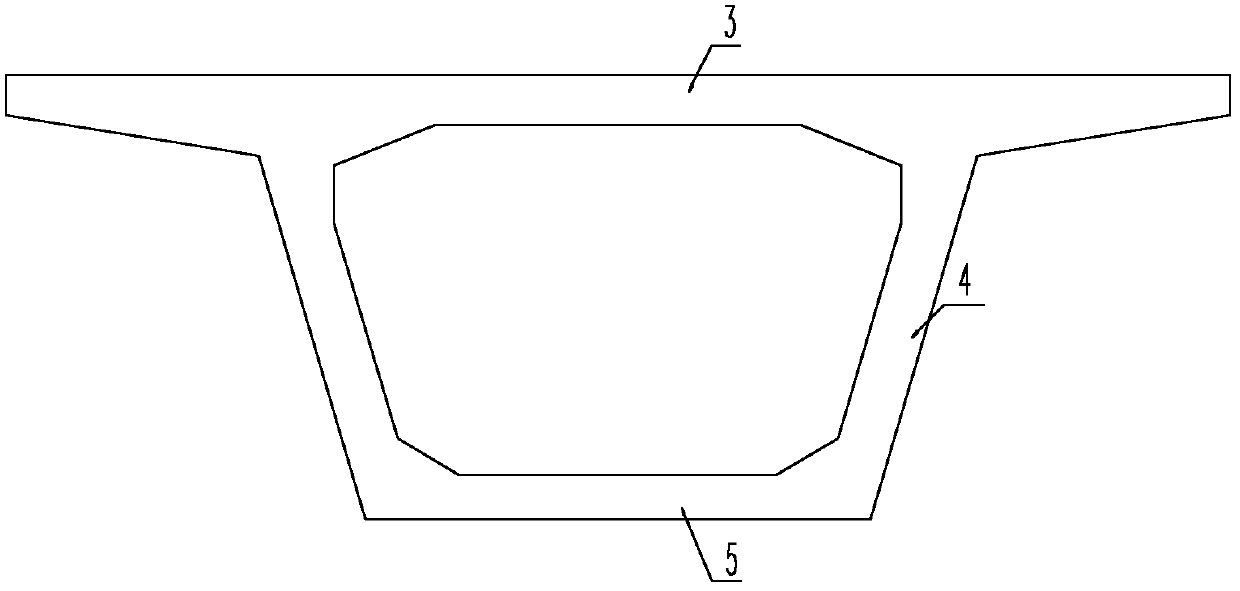

[0121] Step A: Interface treatment of negative moment zone 3 on the concrete box girder roof

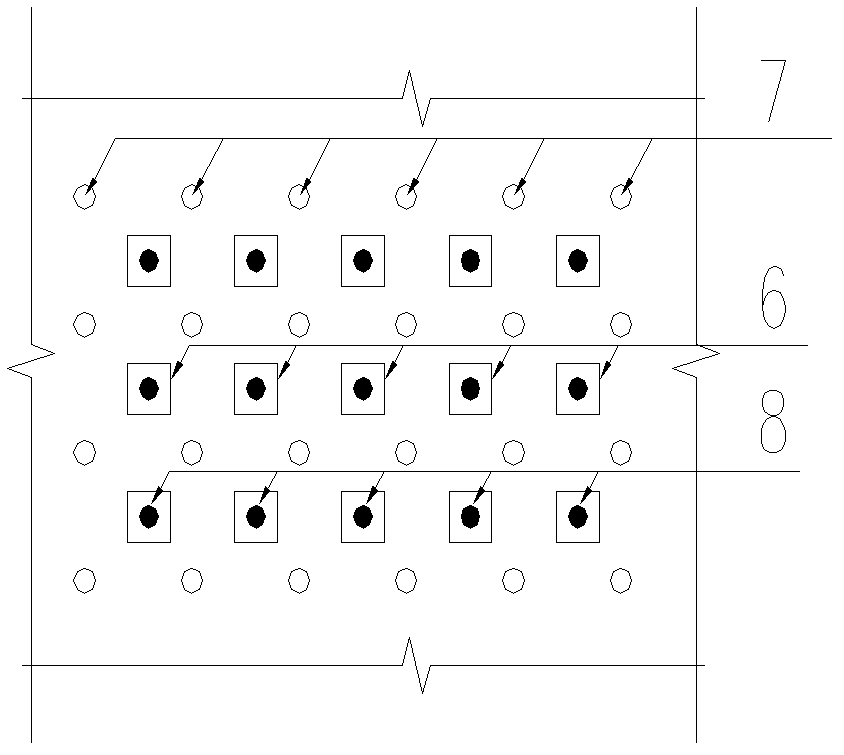

[0122] figure 1 It is a schematic diagram of the unloading of the three-span prestressed concrete continuous box girder bridge, as shown in figure 1 The three-span prestressed concrete continuous box girder bridge shown includes a concrete box girder 1 and a reverse roof support 2 . figure 2 is along figure 1 The cross-sectional view of the A-A line in, that is figure 1 A typical section of the bridge shown. like figure 2 As shown, the typical section of this embodiment includes a concrete box girder roof 3 , a concrete box girder web 4 , and a concrete box girder bottom 5 . Firstly, determine the negative bending moment area of each span, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com