High-performance cement-based shrink-free corrosion-proof grouting agent

A cement-based, non-shrinking technology, applied in the field of high-performance cement-based non-shrinking anti-corrosion grouting agent, can solve the problems of difficult control of the gas generation time and gas generation amount of aluminum powder, achieve excellent filling, reduce environmental pollution, and delay rust. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Component A: 6%; Component B: 45%; Component C: 2%; Component D: 45%;

[0026] Component E: 0.5%; Component F: 0.5%; Component G: 1%.

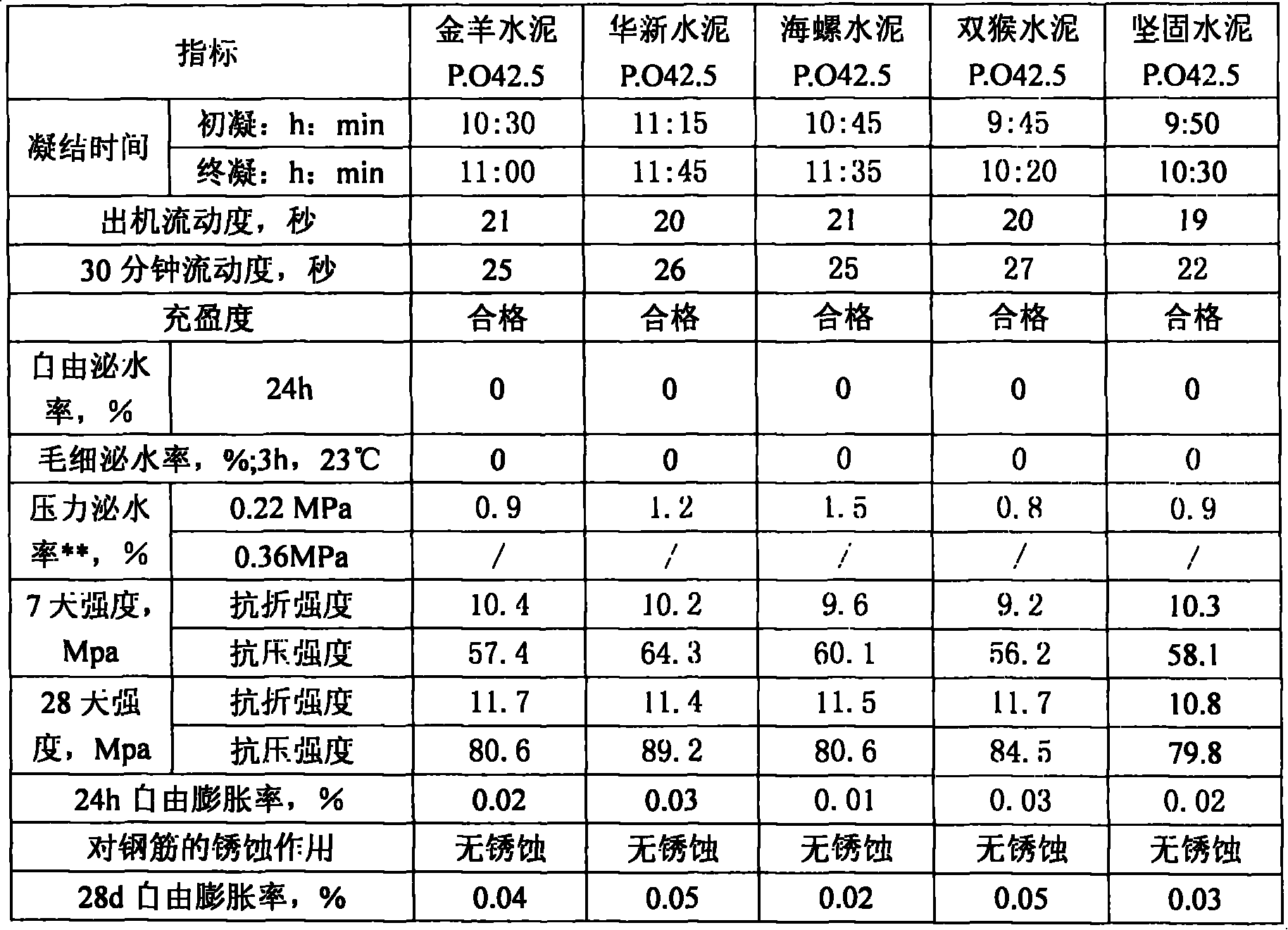

[0027] The present invention is obtained by uniformly mixing the above-mentioned components according to the weight ratio. See Table 1 for the properties of the press grout formed after the present invention mixed with cement (replacing cement 15%) and water prepared by the above formula.

[0028] Properties of grouting material Table 1

[0029]

[0030] Note: the ratio of water to cement used is (i.e. water / (cement+grouting agent) is 0.34, the dosage of the present invention is internal mixing, and the dosage of grouting agent is 5%, 10% and 15%.

[0031] Chemical properties of grouting material: chloride ion content is 0.04%; alkali content (Na 2 (2 equivalent) was 2.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com