Construction method for high-rise concrete structure

A concrete structure and construction method technology, which is applied in the direction of building structure, construction, and building material processing, can solve the problems that the main structure cannot guarantee the anti-seismic requirements, the appearance quality of the product is difficult to guarantee, and hidden safety hazards, etc., so as to shorten the construction time , Improving construction quality and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0015] A kind of high-rise concrete structure construction method, the step that its method comprises is:

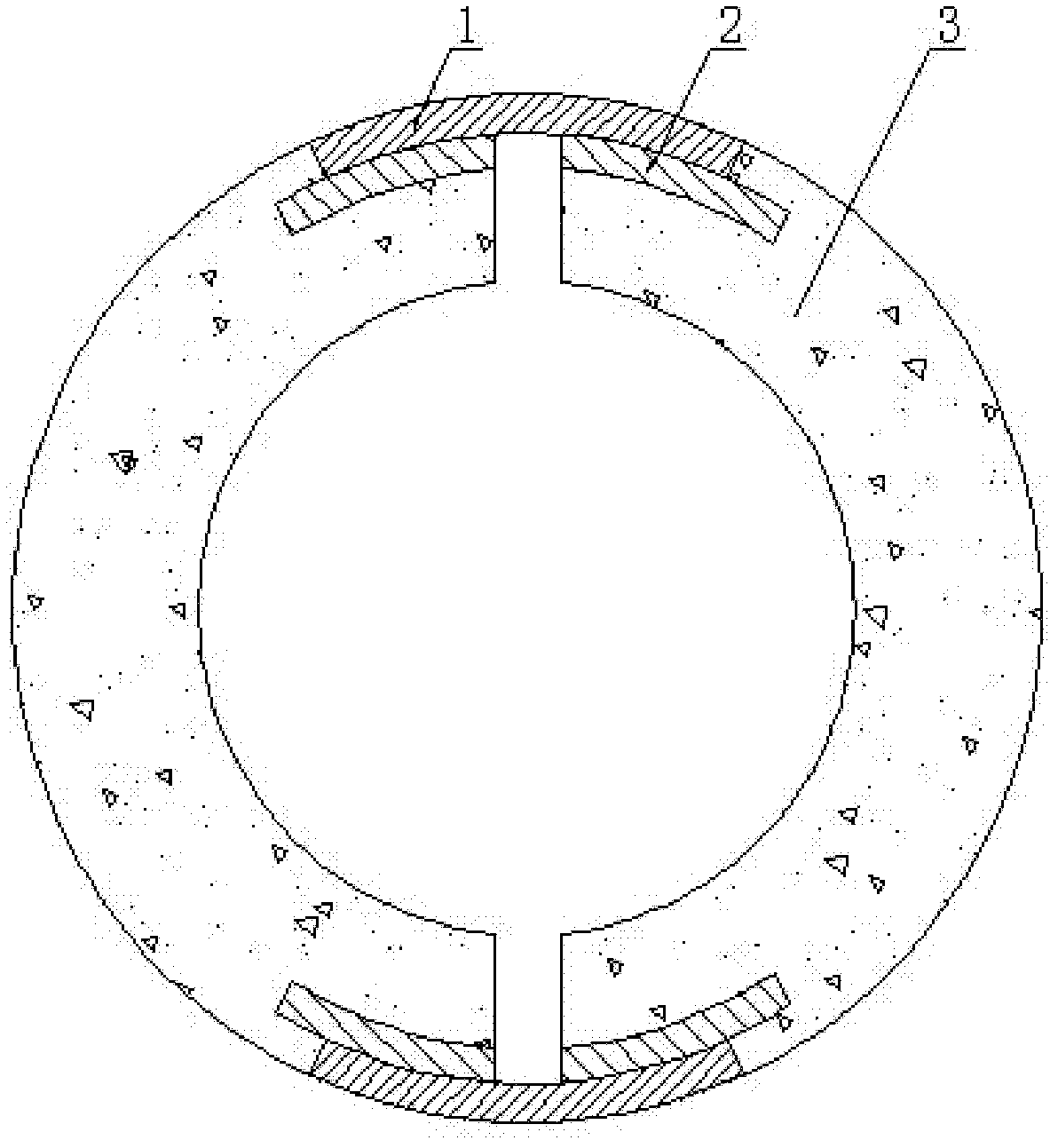

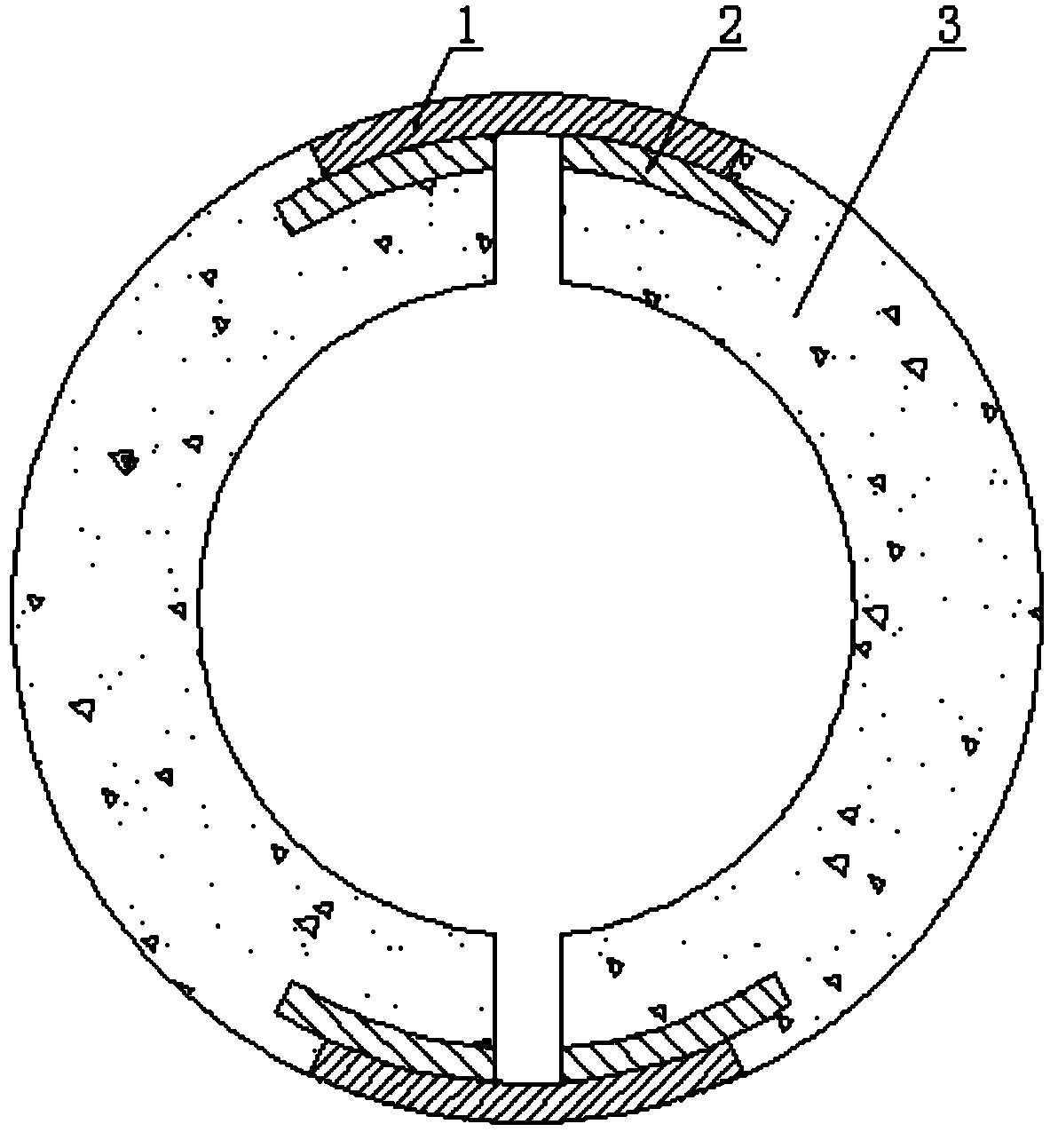

[0016] (1) Concrete column construction: After the steel cage is processed, the tower crane is used to hoist the steel cage as a whole. After the steel cage is installed in place, the high-strength prestressed thin-walled concrete semicircular segment 3 prefabricated in the prefabrication plant will be assembled and positioned. The wall concrete semicircular segment is assembled by prefabricating the embedded steel part 2 and the connecting steel part 1, and then the concrete column is poured with a concrete pump truck, and the concrete column is formed after curing;

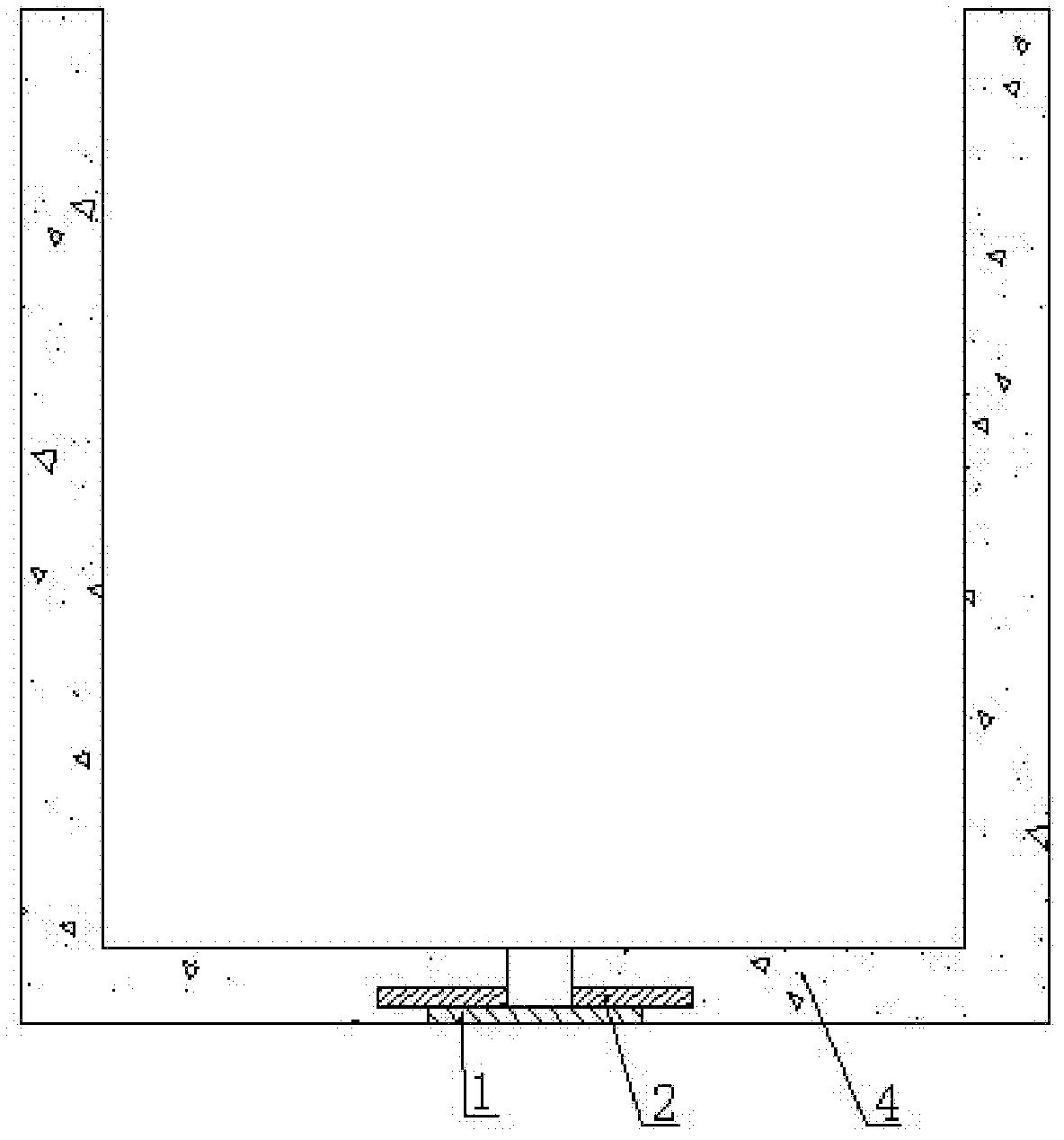

[0017] (2) Concrete beam construction: Install the high-strength pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com