Broken-line reinforcement prestressed concrete pre-tensioned girder construction process

A technology of broken line reinforcement and construction technology, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve the problems of long stretching process time, complex stretching structure, and low construction efficiency, so as to ensure the design prestress , The tensioning process is simple and the construction efficiency is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

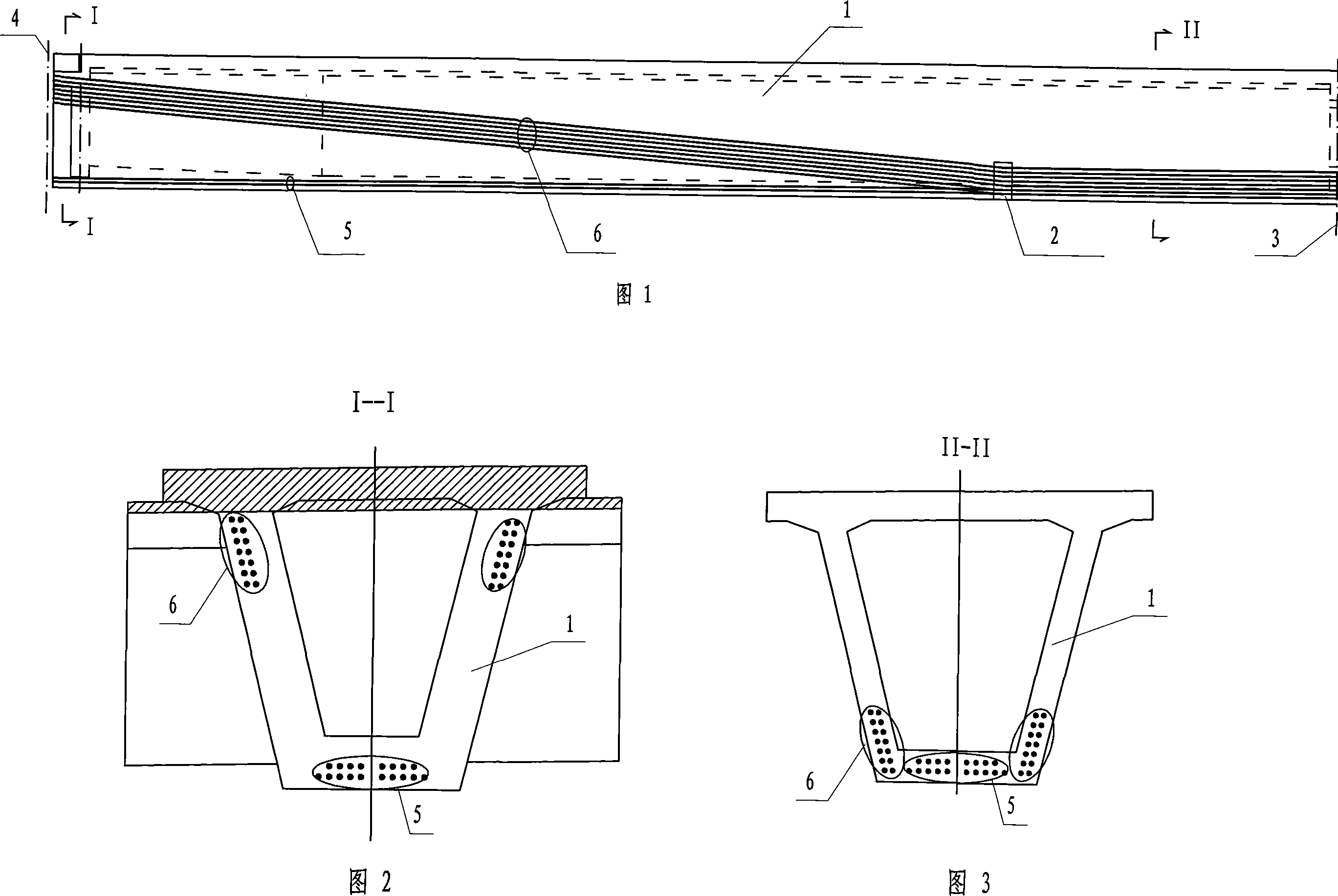

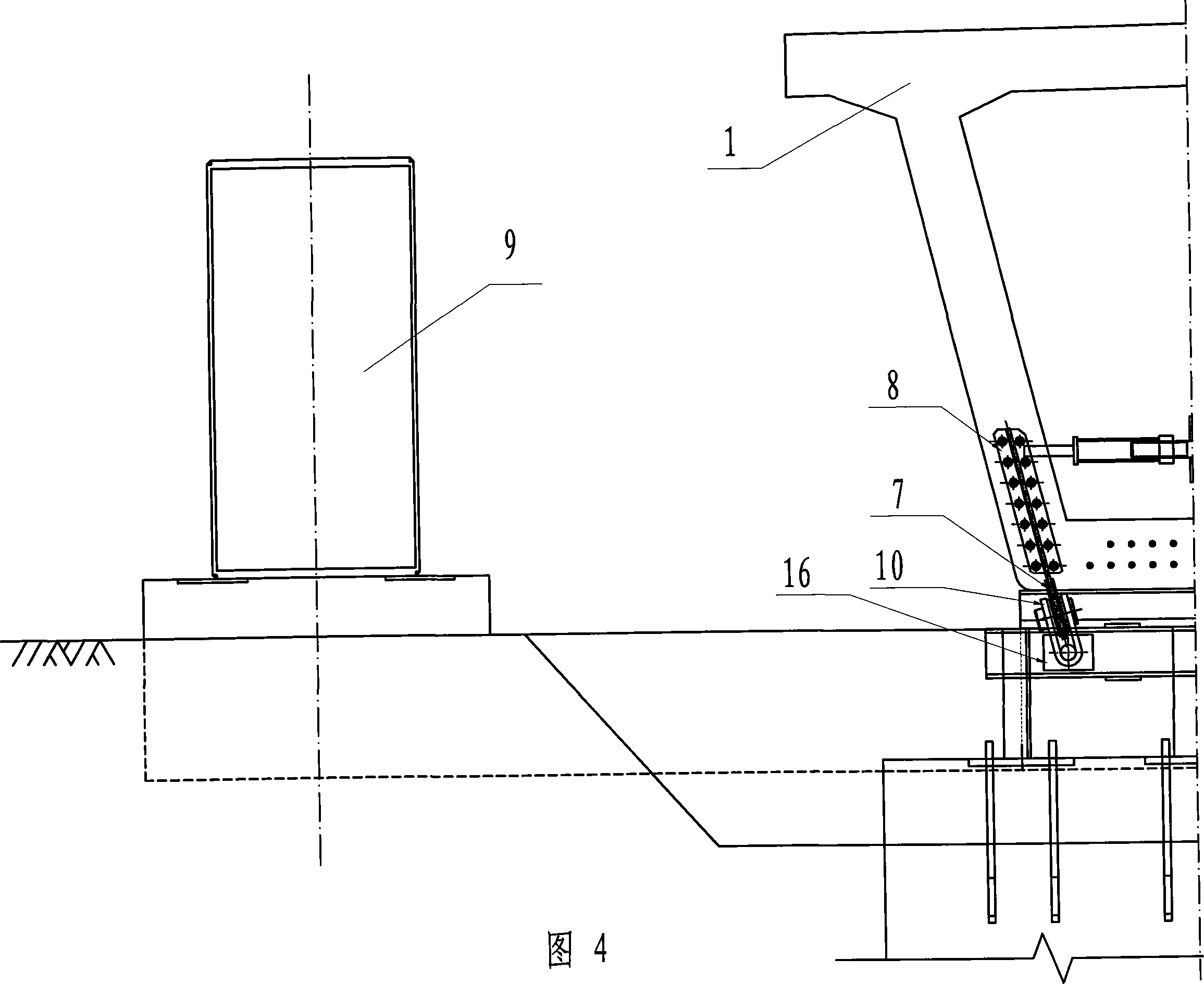

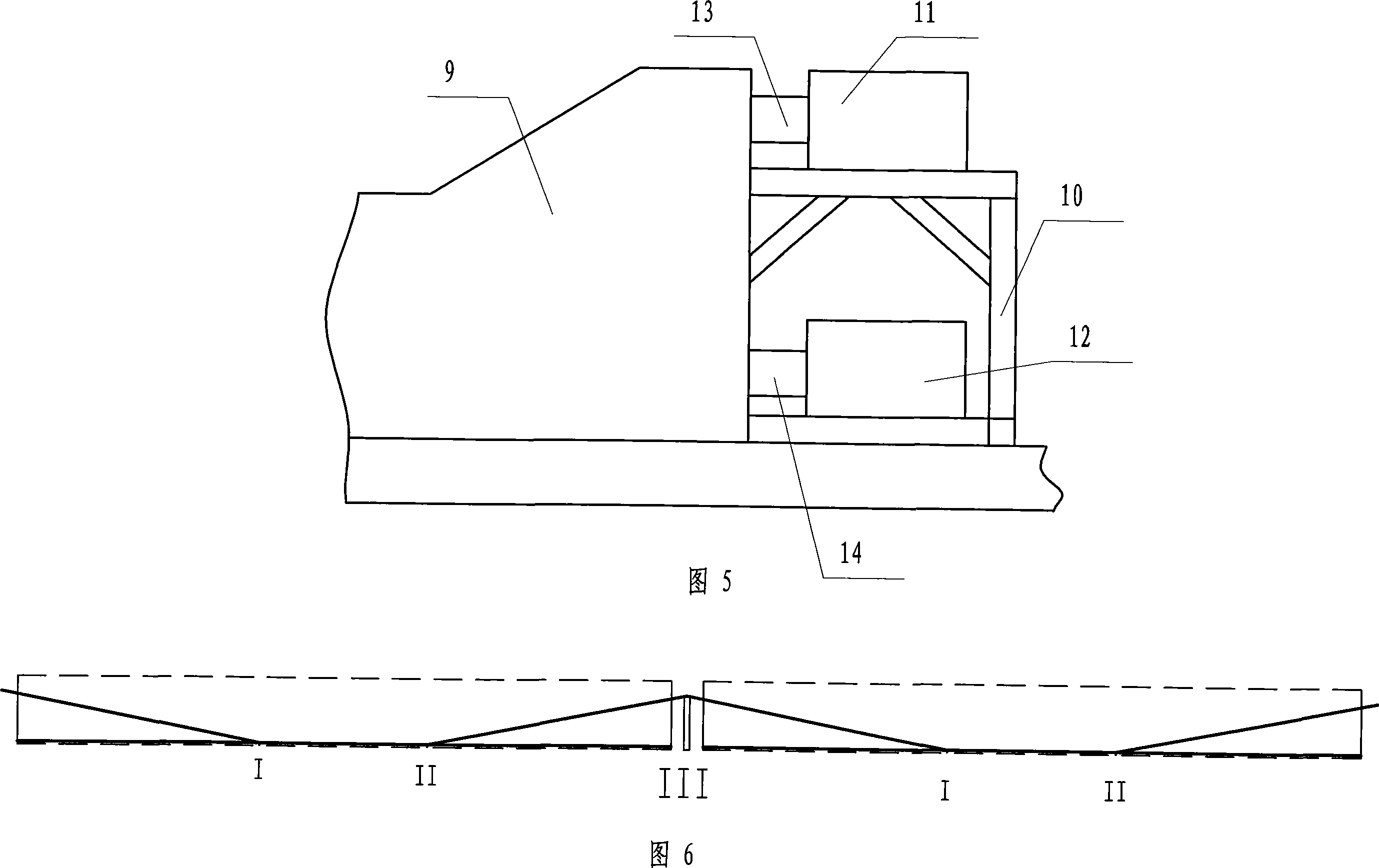

[0039] The construction technology of prestressed concrete pretensioned beam with broken line reinforcement takes the prefabricated prestressed small box girder with 35m pretensioned long line pedestal as an example.

[0040] The structure of the 35m pre-tensioned prefabricated prestressed concrete small box girder is as follows: the width of the top plate of the middle beam is 2.4m, the width of the bottom plate is 1.0m, the height is 1.824m, the thickness of the oblique web is 17.46cm (horizontal thickness is 18cm), and the slope is 1:4; The width of the beam roof is 2.85m (0.45m more than the one-time pouring of the outer flange of the side beam during prefabrication), and the other dimensions are the same as those of the middle beam. 18 (16) φ15.24mm straight steel hinge lines are arranged in the bottom plate of each small box girder in the side span (middle span), and a total of 28 (24) steel hinge lines are arranged in the web (14[12] root) φ15.24mm broken line steel hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com