Interstate highway train system

a technology of interstate highways and train systems, applied in the direction of rope railways, roads, construction, etc., can solve the problems of maglev not being the new future of trains, high cost of installing in rural settings, and high cost of maglev in city limits, so as to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

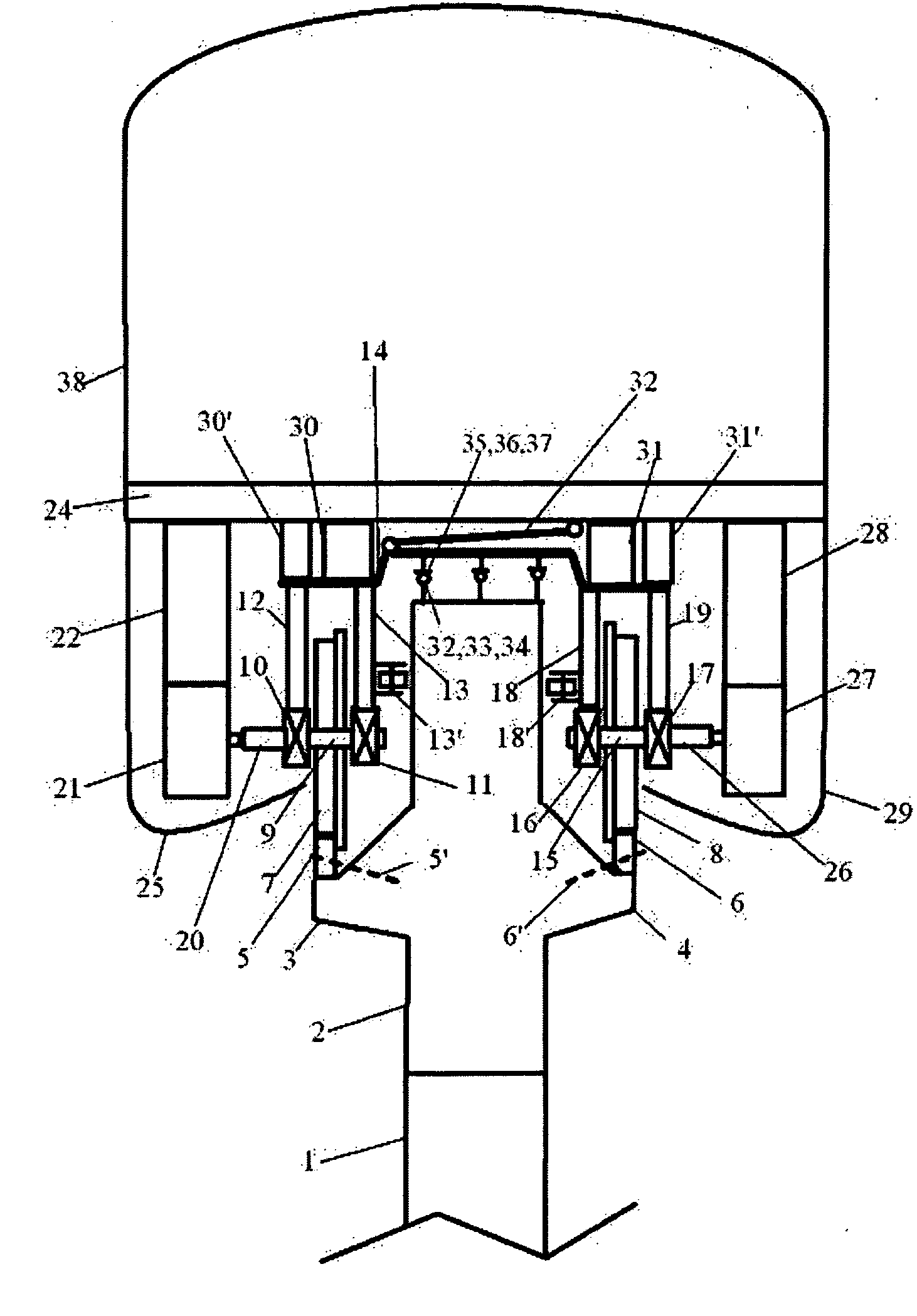

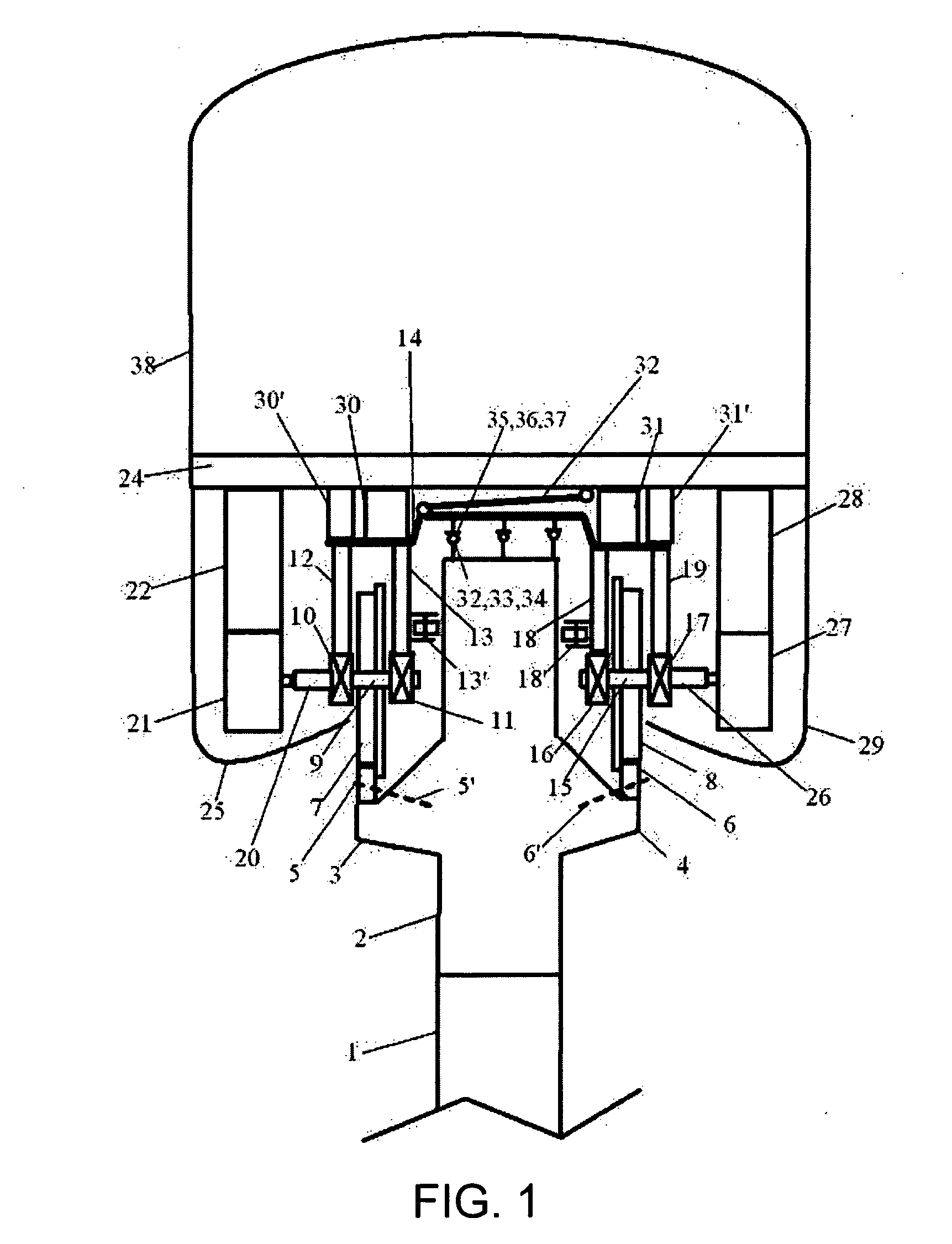

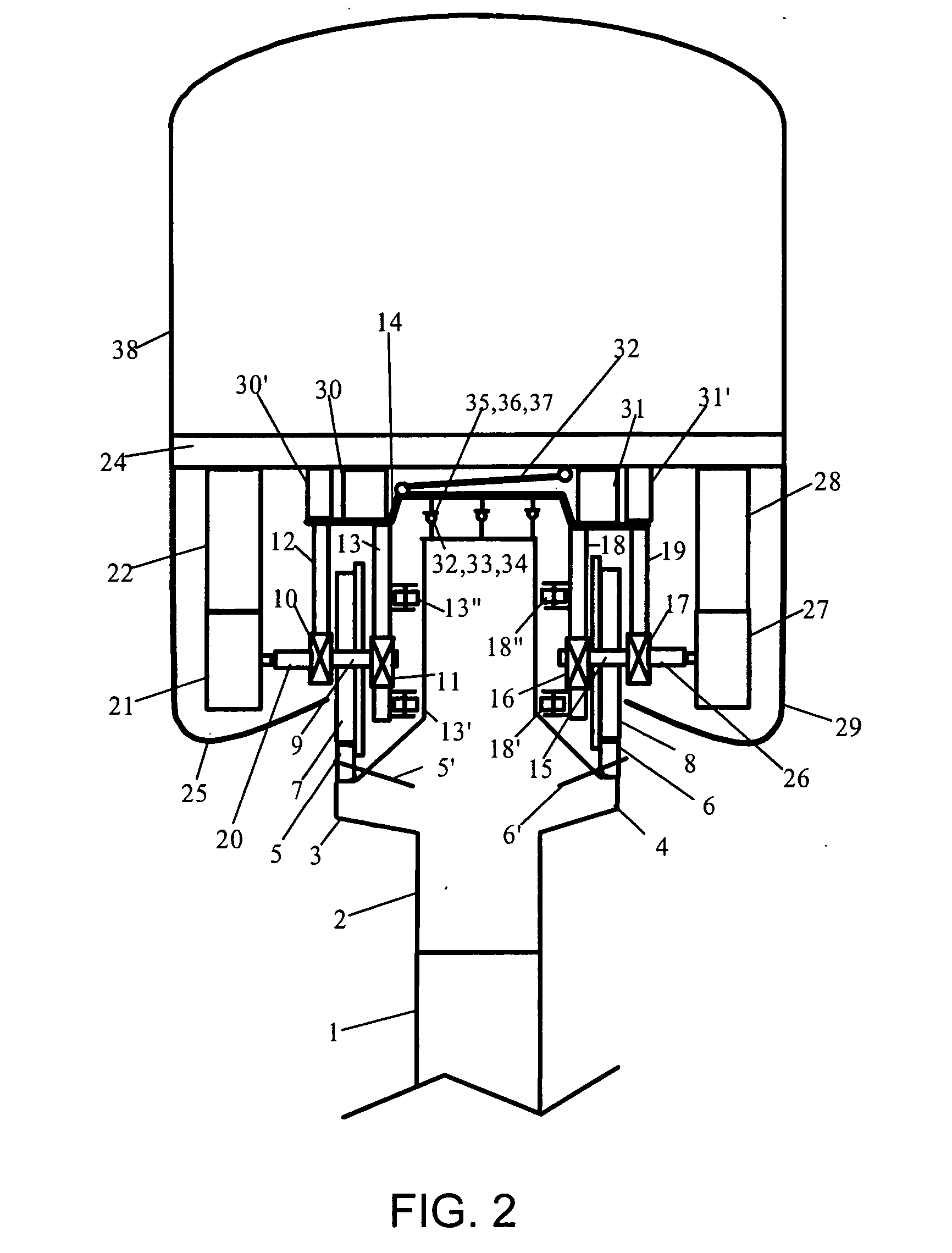

[0035]FIG. 1 shows a train and rail system in accordance with one embodiment of the present invention. The system includes an elevated beam railway and a straddling beam rail vehicle. While the rail vehicle of FIG. 1 is a locomotive, it should be noted that the present invention is applicable to any sort of rail vehicle including rail cars and the like.

[0036] Generally concrete posts or piles 1 supporting rail beam 2 would be spaced and be connected to piles 1 every 120 feet or so depending on the width and thickness of pre-stressed concrete or steel beam 2. All things considered, pile supported beams 2 are probably more economic than at-grade fenced rails foundations, even in deserts, especially considering the economic disadvantages of long fences and due to the potential economic loss that restrictions to local cross traffic can cause. Beam 2 could be steel but generally pre-stressed concrete would be the most cost effective beam support if held under 120 feet between pile suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com