Duct grouting agent for post-tensioning prestressed concrete beams

A technology of channel grouting and prefabricated beams, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem that volume stability, fluidity and other properties cannot meet the high requirements of high-speed passenger railway engineering, channel Problems such as low performance of grouting agent, to achieve the effect of good filling degree and volume stability, adjustable fluidity, and wide construction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The raw material composition ratio of this channel grouting agent is calculated by weight: water reducing component 100kg, late expansion component 550kg, plastic stage expansion component 2kg, water retention component 343kg, defoaming component 3kg, coagulation adjustment component 2kg .

Embodiment 2

[0026] The raw material composition ratio of this channel grouting agent is calculated by weight: water reducing component 110kg, late expansion component 550kg, plastic stage expansion component 5kg, water retention component 330kg, defoaming component 5kg, coagulation adjustment component 0kg .

Embodiment 3

[0028] The raw material composition ratio of this channel grouting agent is calculated by weight: water reducing component 100kg, late expansion component 500kg, plastic stage expansion component 5kg, water retention component 387kg, defoaming component 5kg, coagulation adjustment component 3kg .

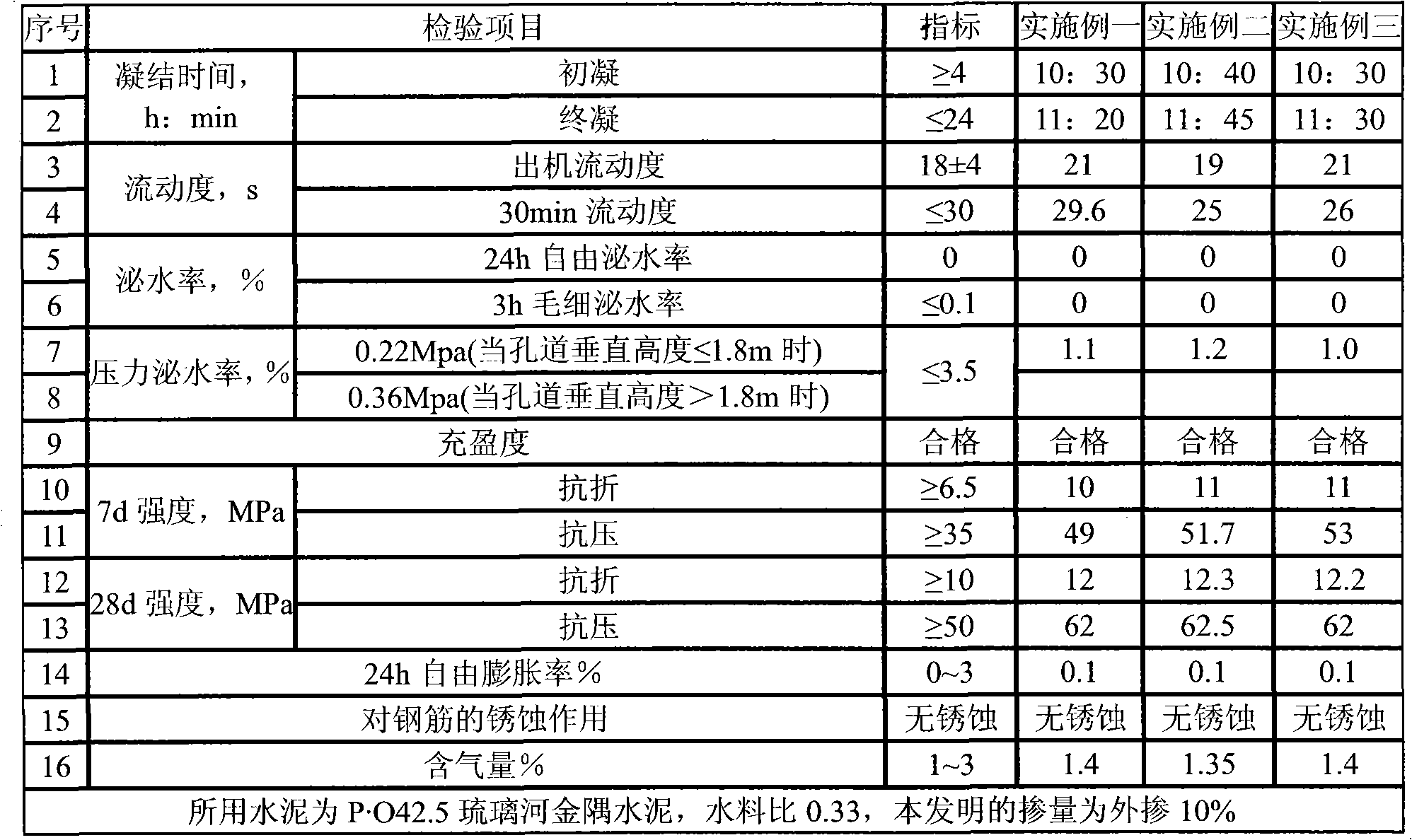

[0029] The present invention is obtained by mixing the above-mentioned components uniformly. The present invention prepared by adopting the above formula is mixed with cement (externally mixed with 10%) and water to form press grout. According to the test method in TB / T3192-2008 "Technical Conditions for Pressure Drop of Railway Post-tensioned Concrete Beam Pipes", the test results are as follows:

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com