Catalysis treatment method for oil field wastewater re-injection

A technology for oil field wastewater and catalytic treatment, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of high viscosity of sewage and difficult separation of oil and water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

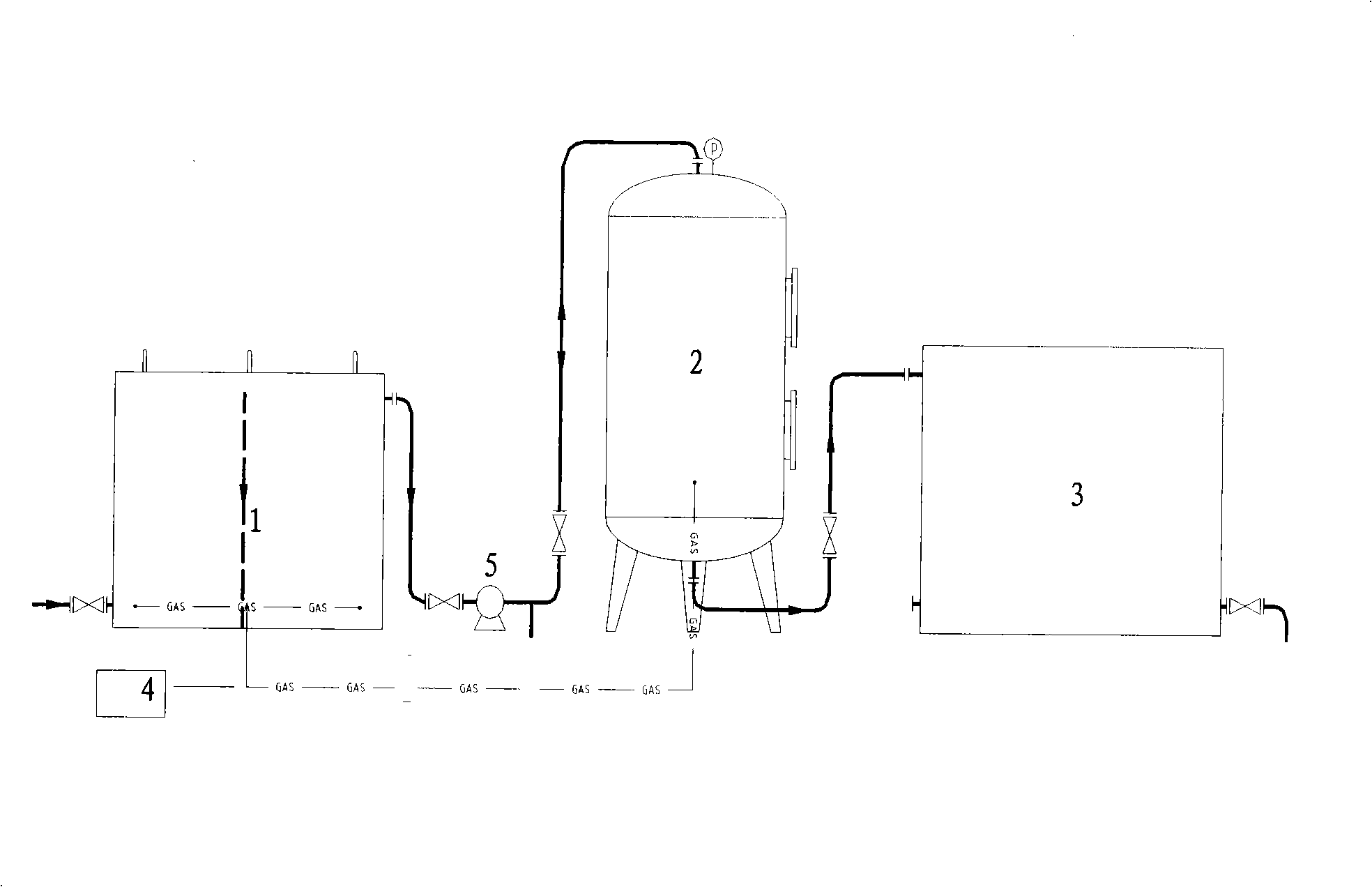

Method used

Image

Examples

Embodiment 1

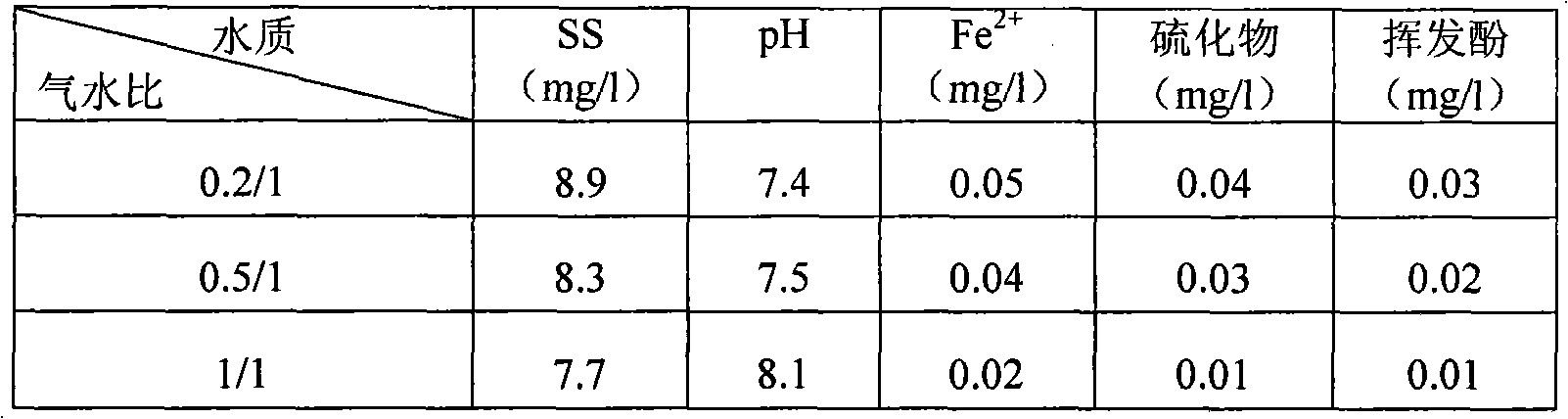

[0021] Example 1 Catalytic treatment experiment of oilfield wastewater under different gas-water ratios

[0022] In the catalytic reactor made of stainless steel, two partitions with micropores are placed in parallel, and two layers of 100ml catalysts of one or more oxides of Fe, Mn or Cu are filled respectively, and the water is fed intermittently by a water pump. 60°C, catalytic reaction time 10min, raw water after precipitation pretreatment water quality is volatile phenol 1.6mg / l, sulfide 4.7mg / l, SS 12.9mg / l and Fe 2+ 3.8mg / l, four different catalysts were used to further catalyze the wastewater under different gas-water ratios, and the results are listed in Table 1-Table 4.

[0023] Table 1. Catalytic treatment results of oilfield wastewater with different gas-water ratios by catalyst (FeMn)

[0024]

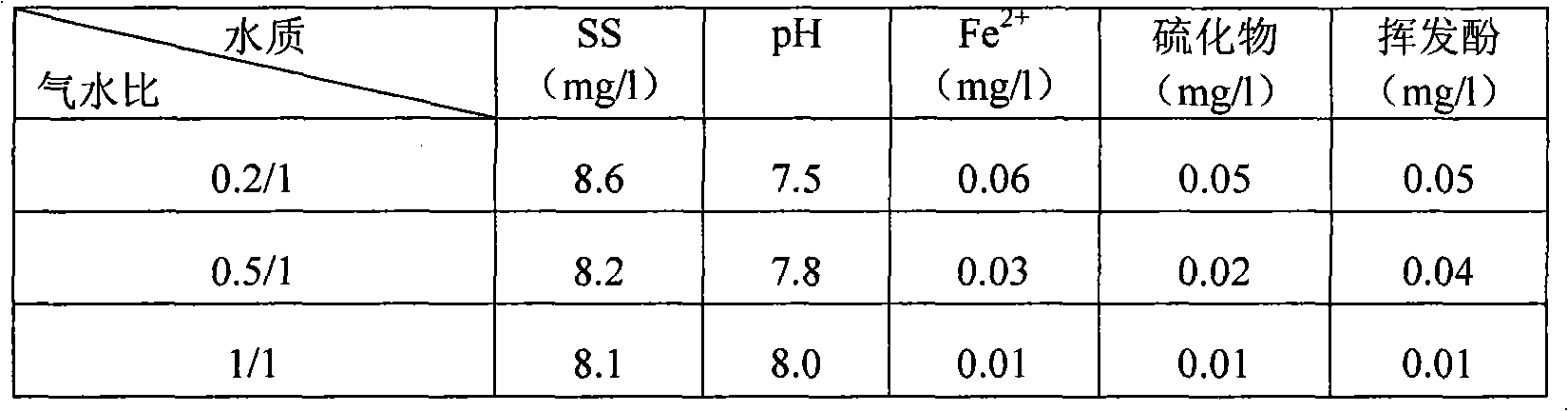

[0025] Table 2. Catalytic treatment results of oilfield wastewater with different gas-water ratios by catalyst (FeCu)

[0026]

[0027] Table 3. Catalytic treatmen...

Embodiment 2

[0032] Catalytic treatment experiment of oilfield wastewater under different aeration reaction time

[0033] In a heterogeneous catalytic reactor made of stainless steel, two partitions with micropores are placed in parallel, and two layers of 100ml catalysts of one or more oxides of Fe, Mn or Cu are filled respectively, and water is fed by a water pump. When the gas-water ratio is 0.5 / 1, the reaction temperature is 60°C, and the raw water is pretreated by precipitation, the water quality is 1.6mg / l of petroleum volatile phenol, 4.7mg / l of sulfide, 12.9mg / l of SS and Fe 2+ 3.8mg / l, four different catalysts were used for further catalytic treatment of wastewater under different aeration reaction times, and the results are listed in Table 5-Table 8.

[0034] Table 5. Catalytic treatment results of oilfield wastewater with different reaction times of catalyst (Fe Mn)

[0035]

[0036] Table 6. Catalytic treatment results of oilfield wastewater with different reaction times of...

Embodiment 3

[0042] Example 3 Comparison Experiment of Catalyst-Free Air Oxidation Treatment of Oilfield Wastewater

[0043]In a heterogeneous catalytic reactor made of stainless steel, two separators with micropores are placed in parallel. When no catalyst is loaded, water is fed by a water pump. The gas-water ratio is 0.5 / 1, the reaction time is 10 minutes, and the reaction temperature is 60 ℃, the quality of the raw water after precipitation pretreatment is 1.6mg / l volatile phenol, 4.7mg / l sulfide, 12.9mg / l SS and Fe 2+ 3.8mg / l, using no catalyst to further treat the wastewater, the results are listed in Table 9.

[0044] Table 9. Treatment results of oilfield wastewater by air oxidation with different aeration gas water ratios without catalyst

[0045]

[0046] From the above experimental results, it can be seen that the oilfield production wastewater is pretreated by sedimentation and then treated by air heterogeneous catalytic oxidation technology, and the effluent meets the requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com