High-barrier double-bond functionalized graphene oxide/polyethylene film and preparation method thereof

A polyethylene film, high barrier technology, applied in flat products, other household appliances, applications, etc., can solve the problems of limited barrier performance improvement, difficult industrial application, complicated operation steps, etc., to achieve excellent film barrier performance, improve phase Capacitance, the effect of large market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

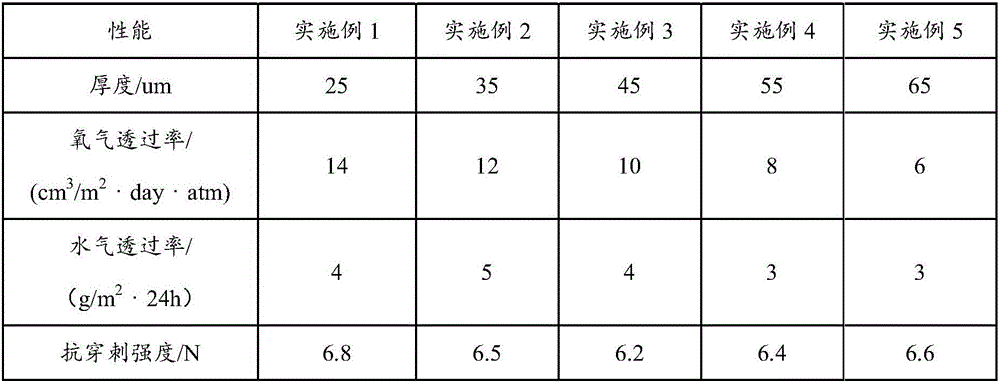

Examples

Embodiment 1

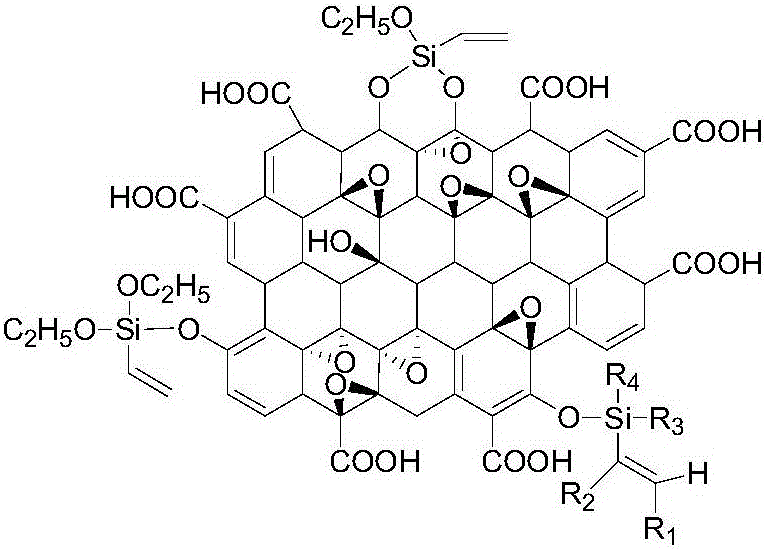

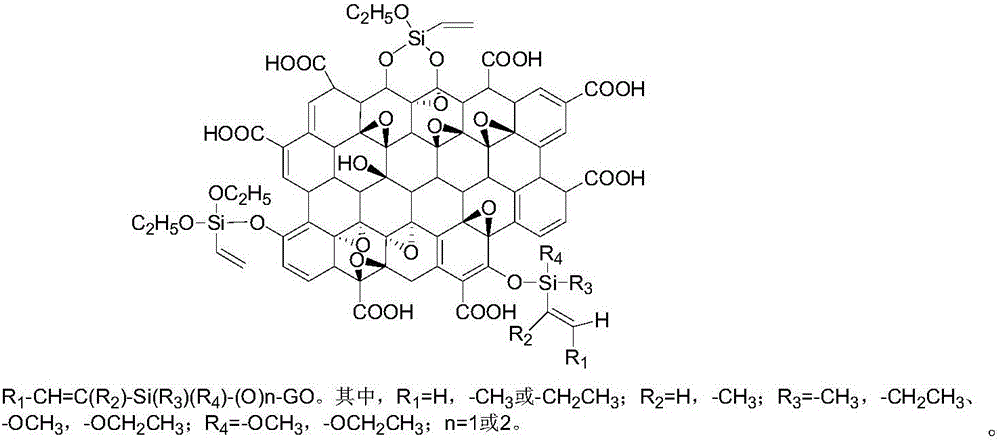

[0034] 1) Preparation of double bond functionalized graphene oxide:

[0035] 1-1) Add 3g graphite to 360mLH 2 SO 4 and 40mLH 3 PO 4 in ice bath, slowly add 18g KMnO 4 and stirred at 50°C; the reaction mixture was cooled to room temperature and placed in ice cubes, and 3 mL of H 2 o 2 (mass fraction 30%); at this moment, the mixed solution changed from purple black to bright yellow; after the mixed solution was filtered, it was centrifugally washed 5 times at 10000r / min with HCl (mass fraction 10%), and the residue was removed; then washed with water, centrifuged , freeze-drying, and ultrasonication to obtain brown graphene oxide GO;

[0036] 1-2) Add 0.3 g of the graphene oxide prepared in 1-1) to an anhydrous ethanol solution of 15 to 30 times the amount (mass ratio), ultrasonically disperse for 10 to 15 minutes, then add 0.5 to 2 times the amount of graphite oxide Vinyltrimethoxysilane with the amount (mass ratio) of vinyl trimethoxysilane, continue to ultrasonically ...

Embodiment 2

[0044] 1) Preparation of double bond functionalized graphene oxide:

[0045] 1-1) Add 3g graphite to 360mLH 2 SO 4 and 40mLH 3 PO 4 in ice bath, slowly add 18g KMnO 4 and stirred at 50°C; the reaction mixture was cooled to room temperature and placed in ice cubes, and 3 mL of H 2 o 2 (mass fraction 30%); at this moment, the mixed solution changed from purple black to bright yellow; after the mixed solution was filtered, it was centrifugally washed 5 times at 10000r / min with HCl (mass fraction 10%), and the residue was removed; then washed with water, centrifuged , freeze-drying, and ultrasonication to obtain brown graphene oxide GO;

[0046] 1-2) Add 0.3 g of the graphene oxide prepared in 1-1) to an anhydrous ethanol solution of 15 to 30 times the amount (mass ratio), ultrasonically disperse for 10 to 15 minutes, then add 0.5 to 2 times the amount ( (mass ratio) of vinyltriethoxysilane, continue to ultrasonically disperse for about 1h; place in an oil bath at 60°C, and...

Embodiment 3

[0054] 1) Preparation of double bond functionalized graphene oxide:

[0055] 1-1) Add 4g graphite to 460mLH 2 SO 4 and 40mLH 3 PO 4 in ice bath, slowly add 20g KMnO 4 and stirred at 50°C; the reaction mixture was cooled to room temperature and placed in ice cubes, and 4 mL of H 2 o 2 (mass fraction 30%); at this moment, the mixed solution changed from purple black to bright yellow; after the mixed solution was filtered, it was centrifugally washed 5 times at 10000r / min with HCl (mass fraction 10%), and the residue was removed; then washed with water, centrifuged , freeze-drying, and ultrasonication to obtain brown graphene oxide GO;

[0056] 1-2) Add 0.4 g of graphene oxide prepared in 1-1) to an anhydrous ethanol solution of 15 to 30 times the amount (mass ratio), ultrasonically disperse for 10 to 15 minutes, then add 0.5 to 2 times the amount ( Mass ratio) of allyltrimethoxysilane, continue to ultrasonically disperse for about 1h; place in an oil bath at 65°C, and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com