Magnetizing and cracking device with tail gas treatment device

A cracking device and tail gas treatment technology, which is applied in gas treatment, combined devices, incinerators, etc., can solve the problems of no heat recovery and comprehensive utilization, no disclosure of tail gas treatment methods, etc., and achieve the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

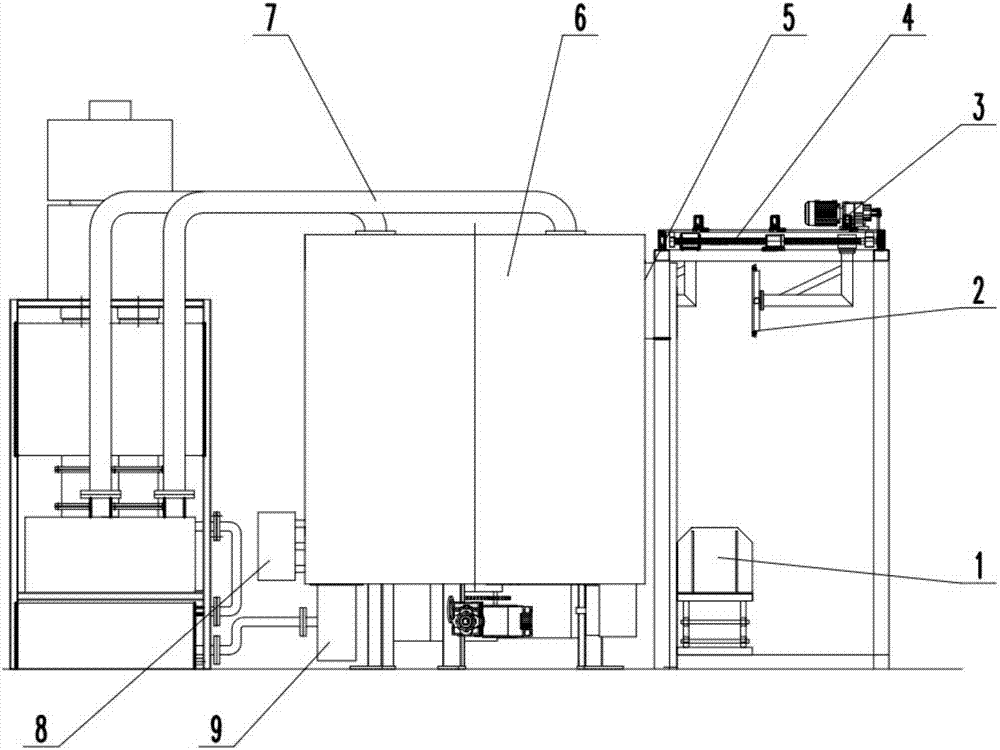

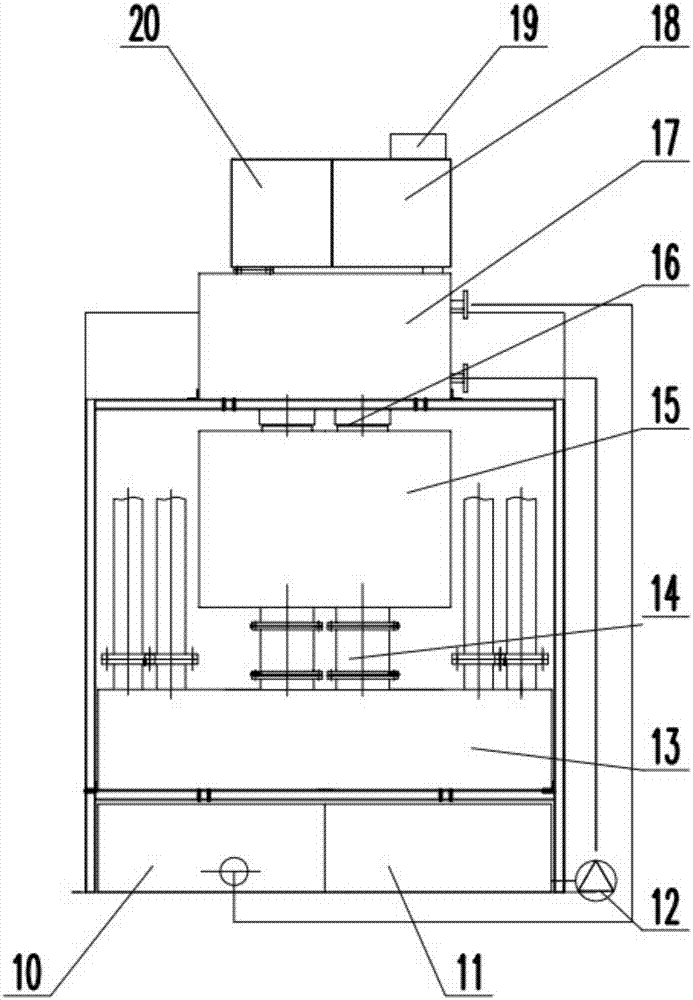

[0037] Attached below figure 1 And attached figure 2 A more detailed description will be given to a magnetization cracking device with a tail gas treatment device of the present application.

[0038] figure 1 It is a structural schematic diagram of a magnetization cracking device with tail gas treatment device in the present invention.

[0039] Such as figure 1 As shown, the magnetization cracking device with tail gas treatment device includes a magnetization cracking device and a tail gas treatment device, the tail gas treatment device is connected to the exhaust port of the magnetization cracking device, and the magnetization cracking device is used for magnetization cracking of organic waste , the tail gas treatment device is used to process the tail gas produced by the magnetization cracking device, not only all the data of the tail gas discharged meet the national standard requirements, especially the dioxin project is significantly lower than the national standard re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com