Method for immobilizing nutrients in cow dung water by alum

A technology of cow dung and alum, which is applied in the field of resource utilization of agricultural waste, can solve the problems of biogas having no economic value, high equipment maintenance cost, and high use cost, and achieve good ecological and environmental benefits, convenient operation, and improved utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

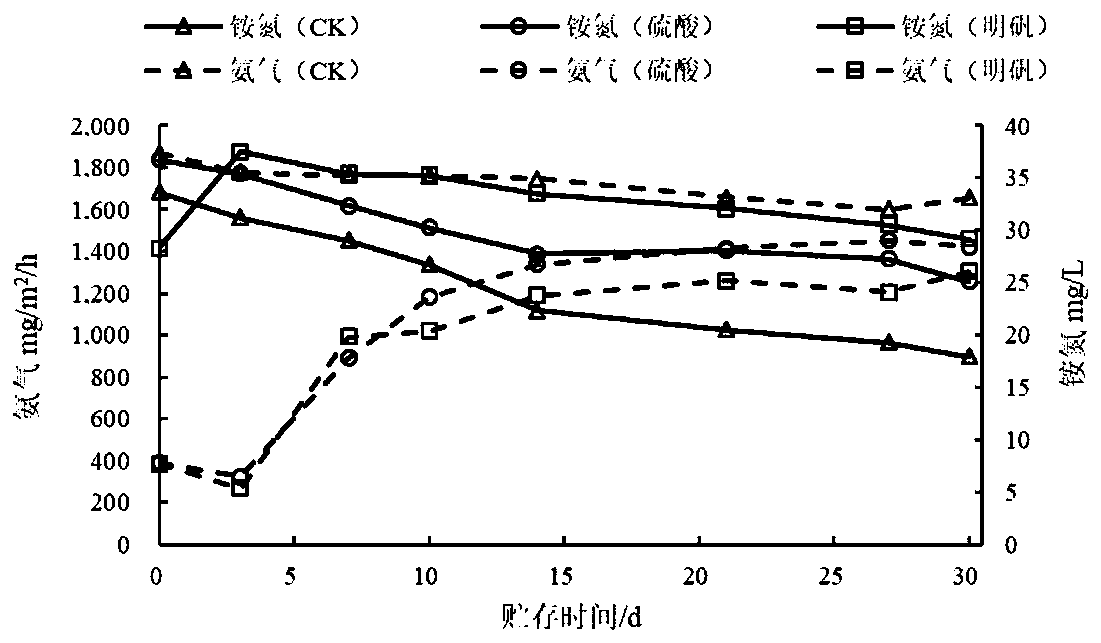

[0027] will be 1m 3 The cow dung water is passed into the adjustment tank, a total of 20kg of alum is added, and the stirring is continued to adjust the pH of the dung water to 6.0. After the pH is adjusted, the dung water added with alum is passed into the storage tank for storage. Cattle breeding manure comes from the manure of dairy farms using the process of flushing manure with water (the manure is first dried and cleaned to the manure canal, and then washed to the solid-liquid separation device with water), after solid-liquid separation, the initial pH of the manure without adding alum is 8.25, ammonium nitrogen is 1681.68mg / L, ammonia gas emission flux is 37.40mg / m 2 / h, the solid content rate is 3.08%, and the number of fecal coliform bacteria is 9.2×10 6 MPN / L. Ammonia emission flux after adding alum in cow dung water is 7.68g / m 2 / h, the concentration of ammonium nitrogen is 1416.54mg / L, and the test storage time is 30 days.

[0028] In this example, after 30 day...

Embodiment 2

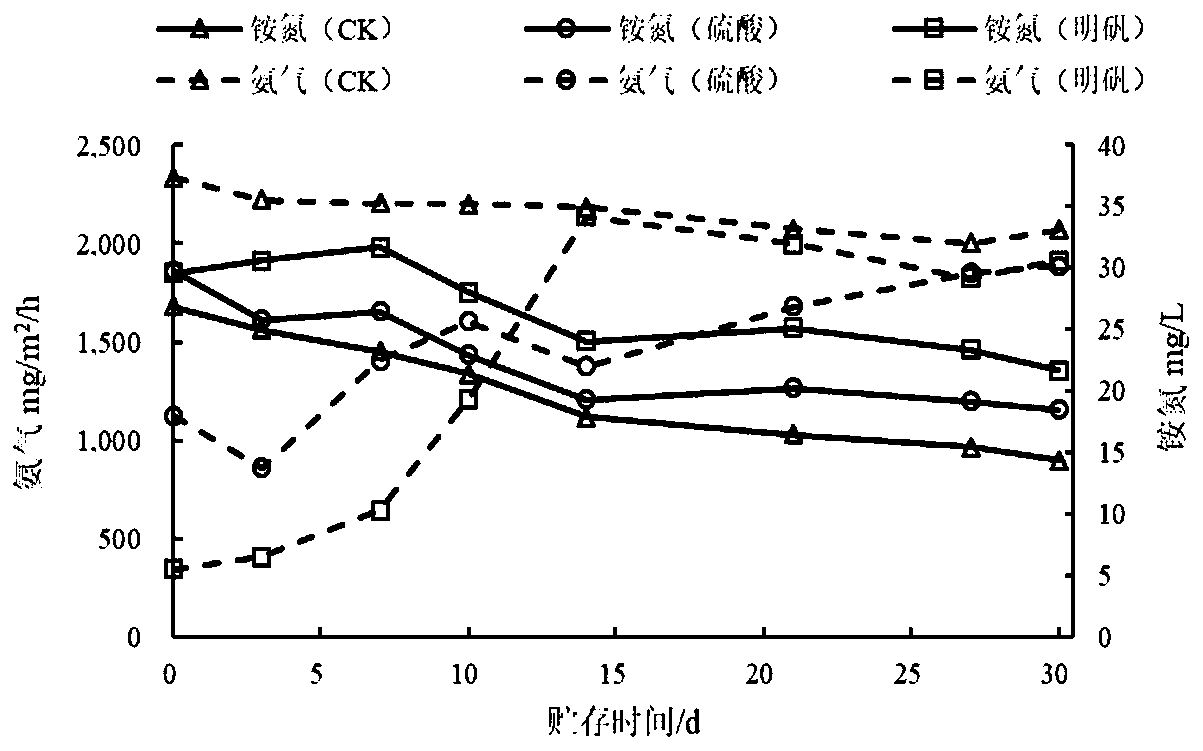

[0030] will be 1m 3 The cow dung water is passed into the adjustment tank, a total of 12kg of alum is added, and the stirring is continued to adjust the pH of the dung water to 6.5. After the pH is adjusted, the dung water added with alum is passed into the storage tank for storage. The cow dung water comes from the dairy farm dung water with water flushing dung process (the dung is first dried and cleaned to the dung ditch, and then washed with water to the solid-liquid separation device). After solid-liquid separation, the initial pH of the dung water without adding alum is 8.25 , the ammonium nitrogen is 1681.68mg / L, and the ammonia emission flux is 37.40mg / m 2 / h, the solid content rate is 3.08%, and the number of fecal coliform bacteria is 9.2×10 6 MPN / L. Ammonia emission flux after adding alum in cow dung water is 5.45g / m 2 / h, the concentration of ammonium nitrogen is 1848.84mg / L, and the test storage time is 30 days.

[0031] After 30 days of storage of the feces w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com