Method for treating organic wastewater by efficient peroxide flocculation technology

A high-efficiency peroxygen flocculation and technical treatment technology, applied in the field of environmental engineering, can solve the problems of poor treatment effect of high-concentration organic wastewater, large amount of anode loss sludge, and limited electric Fenton technology, etc., to achieve wide working range and saving Disposal costs and the effect of reducing the amount of sludge generated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described in detail through the following embodiments in conjunction with the accompanying drawings.

[0020] In the process of peroxyflocculation, the anode is an iron plate, and the cathode is a carbon felt modified with carbon black and PTFE; in the electroflocculation system, the anode is an iron plate and the cathode is a stainless steel plate; in the electro-Fenton system, the anode is a carbon dioxide Lead and cathode are carbon felt modified with carbon black and PTFE.

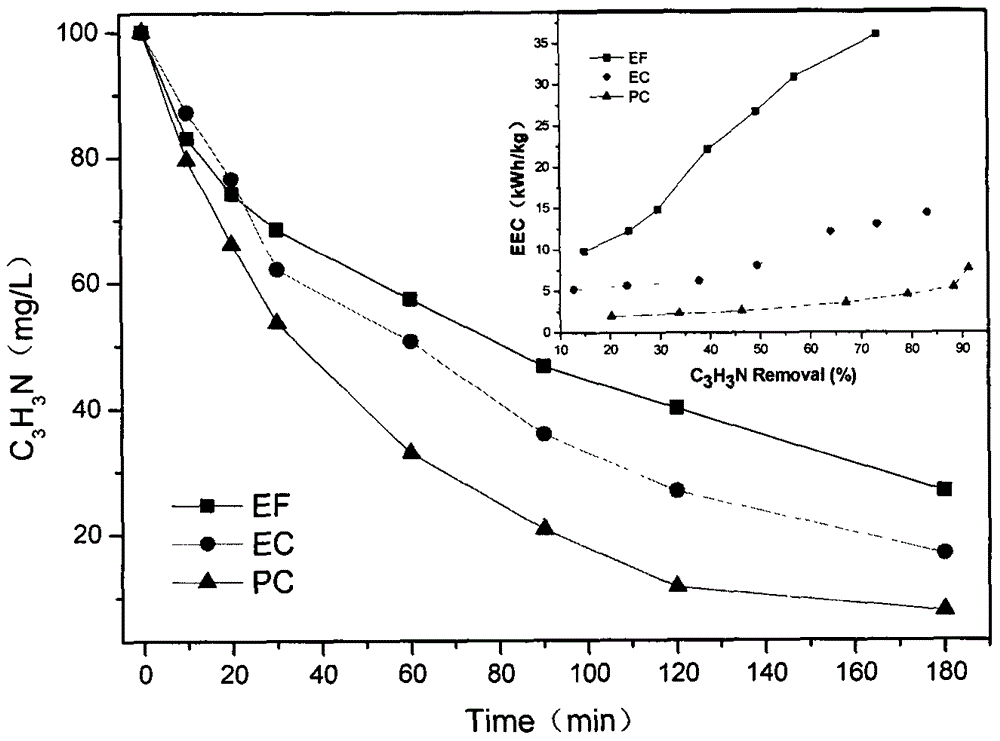

[0021] figure 1 It is the comparison of peroxy flocculation, electro-Fenton and electro-Fenton systems under the conditions of acrylonitrile concentration of 100 mg / L, current of 100 mA, aeration rate of 80 mL / min, and pH of 7. As can be seen from the figure, compared with electro-Fenton and electro-flocculation, peroxyflocculation has the highest degradation rate of acrylonitrile and the lowest energy consumption.

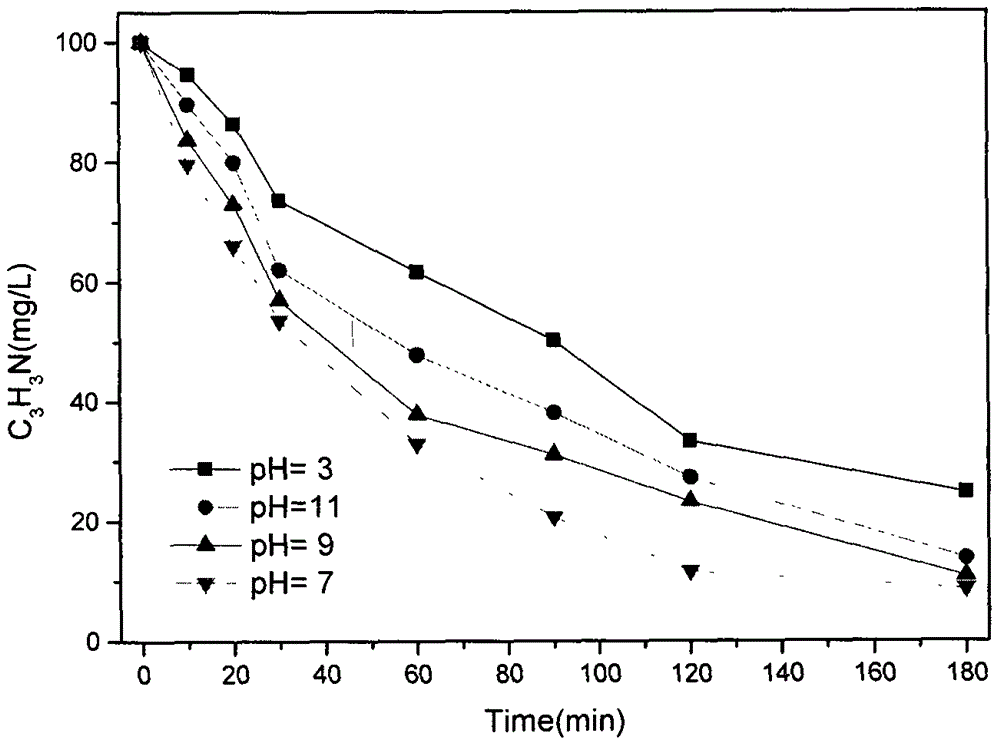

[0022] figure 2 The effect of pH on the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com