Optimization method for fertilizer wastewater treatment process

A technology for wastewater treatment and process optimization, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. The effect of improving total nitrogen removal capacity, improving carbon-nitrogen ratio, and high compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The technological process of the fertilizer wastewater treatment system is: regulating tank - primary aeration tank - primary sedimentation tank - A / O (anoxic tank - aerobic tank) - secondary sedimentation tank - flocculation sedimentation tank - effluent.

[0046] In this example, the high-concentration ammonia nitrogen and COD waste water from the fertilizer plant is aerated through the blower aeration tube at the bottom of the regulating tank to make it evenly mixed.

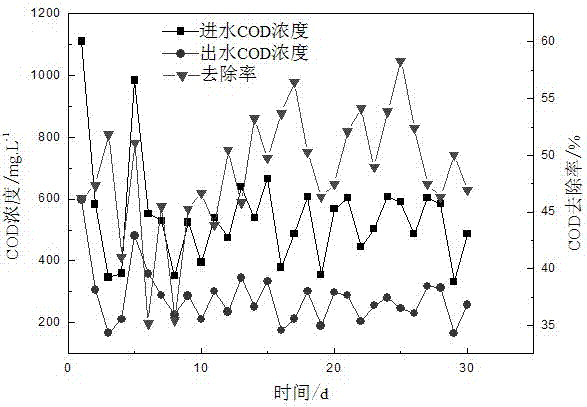

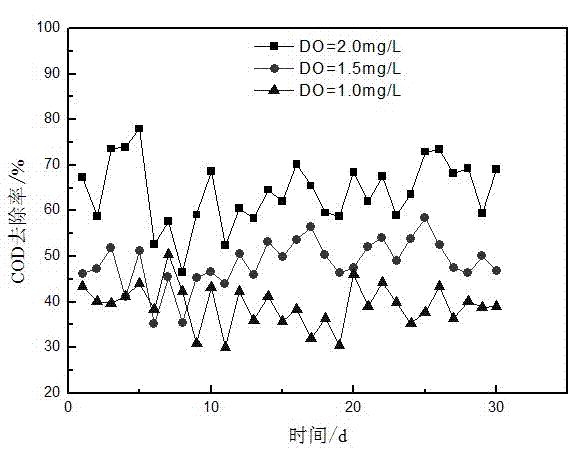

[0047] The operation regulation of the initial exposure tank is very critical to the operation effect of the whole system. The main function of the initial aeration tank is to remove part of the COD in the wastewater. The COD removal rate of this pond directly affects the supply of carbon source required for denitrification in the subsequent anoxic pond. As a main factor affecting the COD removal rate of the initial exposure tank, DO's optimal regulation is extremely important.

[0048] After the eff...

Embodiment 2

[0051] The denitrification effect of the A / O section directly affects the total nitrogen removal efficiency of the process. The control operation parameters are: initial aeration tank DO is 0.8mg / L, sludge reflux ratio r 1 100%; the DO of the aerobic tank is 2.4 mg / L, the pH is controlled between 7.5-8.0, the sludge concentration MLSS is 3000mg / L, and the sludge reflux ratio is r 2 75%.

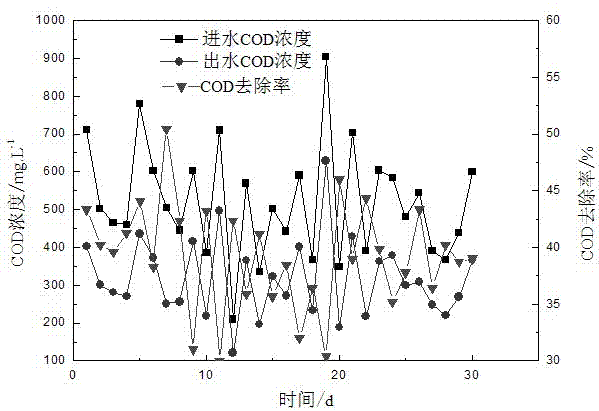

[0052] Through the adjustment of water quality by the regulating tank, when R=200%, the average concentration of COD, ammonia nitrogen and total nitrogen in the system feed water are 435.87mg / L, 53.91mg / L and 57.30mg / L respectively; when R=300%, the system The average concentrations of influent COD, ammonia nitrogen, and total nitrogen are 518.40mg / L, 82.15mg / L, and 86.30mg / L respectively; when R=400%, the average concentrations of system influent COD, ammonia nitrogen, and total nitrogen are 434.07mg / L, 68.93mg / L and 73.84mg / L.

[0053] Figure 5 It is the change chart of COD removal ef...

Embodiment 3

[0058] When the water quality is relatively stable, working condition 1 adopts the parameters before optimization: DO in the initial aeration tank is 0.9mg / L, and the sludge return ratio is r 1 is 100%, the DO in the aerobic tank is 2.0mg / L, the pH is 7.5~8.0, the reflux ratio of nitrifying liquid is 400%, and the sludge reflux ratio is r 2 75%. Working condition 2 is operated with optimized parameters: initial aeration tank DO is 0.9mg / L, sludge reflux ratio r 1 is 100%, the DO in the aerobic tank is 2.0mg / L, the pH is 7.5~8.0, the reflux ratio of nitrifying liquid is 300%, and the sludge reflux ratio is r 2 is 100%.

[0059] The operation results under different working conditions are shown in Table 1. In the table, except for the removal rate (%), the units of other indicators are mg.L -1 .

[0060] Table 1 Comparative analysis of running results under different working conditions

[0061]

[0062] The operation results show that the optimized process parameters a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com