Bird pecking prevented optical cable and manufacturing method thereof

An anti-bird pecking and optical cable technology, applied in the field of cables, can solve the extremely difficult problem of effectively resisting bird attack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

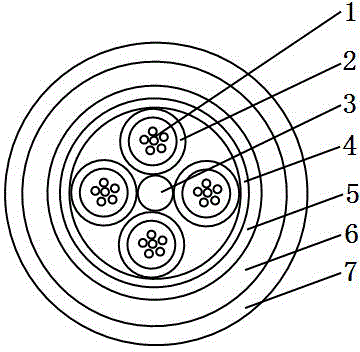

[0071] please see figure 1 , anti-bird pecking optical cable, which includes four loose tubes 2 distributed outside the strength member 3, a protective layer 4 outside the loose tube, an inner sheath 5 outside the protective layer, and located between the inner sheath The outer outer sheath 7 contains six optical fibers 1 in each loose tube, and is characterized in that there is an anti-peck layer 6 between the inner sheath and the outer sheath, and the anti-peck layer is made of the following raw materials in parts by weight Composition: medium-density polyethylene or low-density polyethylene or high-density polyethylene: 50-80 parts; grade 617 or grade 677 epoxy resin: 10-20 parts; diameter 10-80 μm, length / diameter ratio 5-20 ultra-fine steel fibers or glass fibers with a length of 0.1-1 mm and a diameter of 0.03-1 mm or silica optical fibers with a diameter of 6.5-260 μm and a length of 0.03-1 mm: 40 to 60 parts; EVA hot melt adhesive : 5-10 parts; Antioxidant for cable s...

Embodiment 2

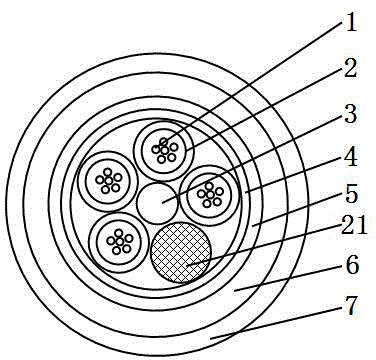

[0081] please see figure 2, anti-bird pecking optical cable, which includes four loose tubes 2 distributed outside the reinforcement 3 and a large filling rope 21, a protective layer 4 located outside the loose tube and the large filled rope, located outside the protective layer The inner sheath 5, the outer sheath 7 outside the inner sheath, each loose tube contains at least one optical fiber 1, which is characterized in that there is an anti-peck layer 6 between the inner sheath and the outer sheath, The anti-peck layer is composed of the following raw materials in parts by weight: medium-density polyethylene or low-density polyethylene or high-density polyethylene: 50-80 parts; epoxy resin with brand 617 or brand 677: 10-20 parts Parts; ultra-fine steel fibers with a diameter of 10-80 μm and a length / diameter ratio of 5-20, or glass fibers with a length of 0.1-1 mm and a diameter of 0.03-1 mm, or binary fibers with a diameter of 6.5-260 μm and a length of 0.03-1 mm. Silic...

Embodiment 3

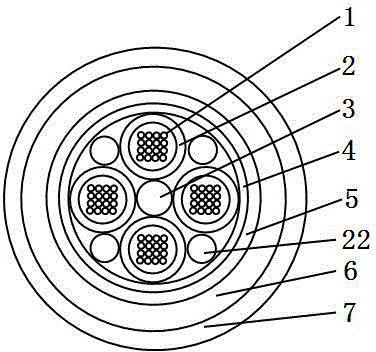

[0092] please see image 3 , anti-bird pecking optical cable, which includes four loose tubes 2 distributed outside the reinforcement 3, small filling ropes 22 located in the outer gaps of adjacent loose tubes, outside the loose tubes and small filling ropes The protective layer 4, the inner sheath 5 outside the protective layer, the outer sheath 7 outside the inner sheath, each loose tube contains sixteen optical fibers 1, and the optical fibers are located in the optical fiber ribbon , the optical fiber ribbon is located in the loose tube, characterized in that there is an anti-pecking layer 6 between the inner sheath and the outer sheath, and the anti-pecking layer is composed of the following raw materials in parts by weight: medium density polyethylene or low density polyethylene Ethylene or high-density polyethylene: 50-80 parts; epoxy resin with grade 617 or grade 677: 10-20 parts; ultra-fine steel fibers or lengths with a diameter of 10-80 μm and a length / diameter rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com