Fluidized bed film bioreactor for sewage treatment

A technology of membrane bioreactor and fluidized bed, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve complex condition control, poor denitrification effect, and huge equipment and other problems, to achieve the effect of improving processing capacity, saving energy consumption, and high volume load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

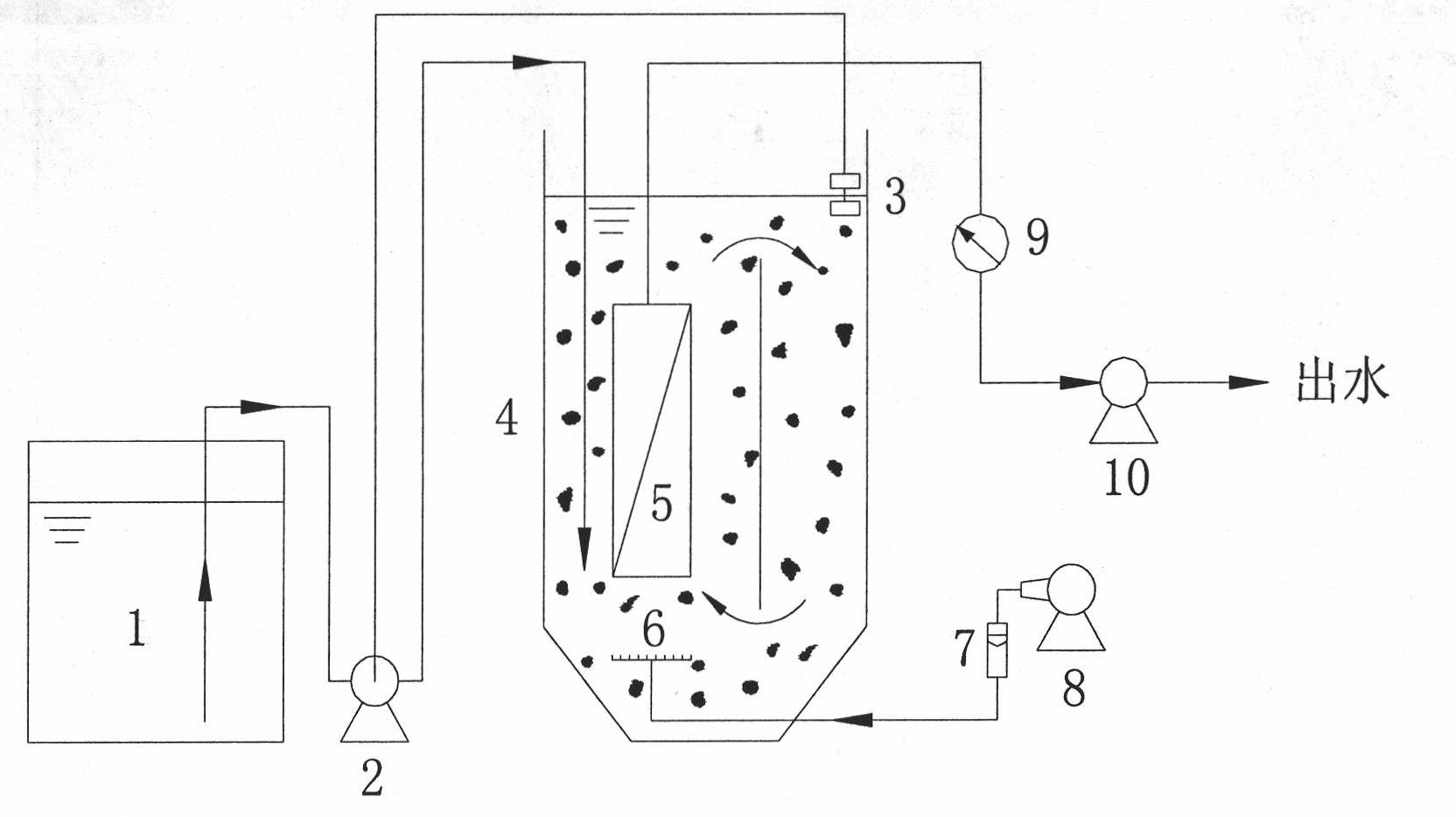

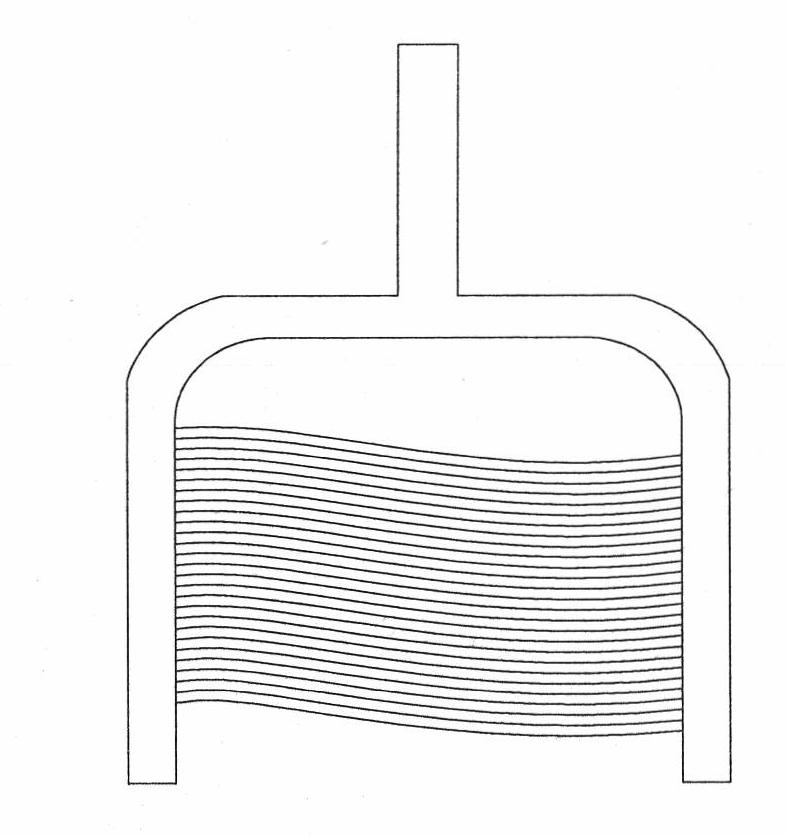

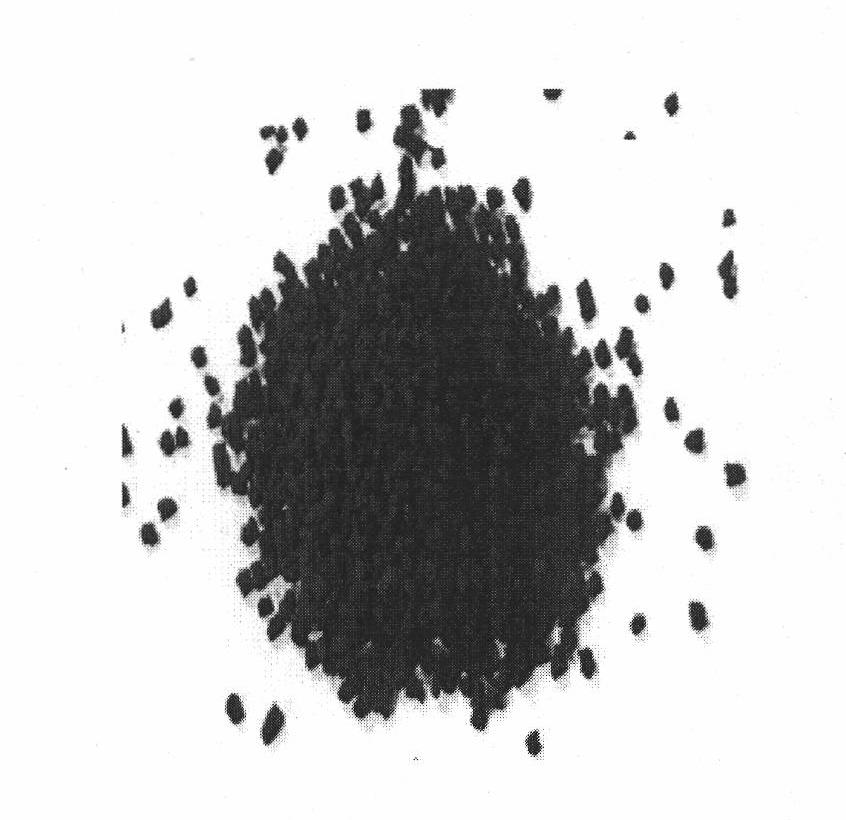

[0025] figure 1 It is a diagram of a fluidized bed membrane bioreactor device, including a reactor system (4), a membrane module (5), a peristaltic pump (2) and (10) to control the influent flow and the effluent flow to adjust the hydraulic retention time (HRT). The reactor is filled with carrier particles with a diameter of about 5mm made by waste rubber powder, activated carbon and binder. The air enters the reactor from the air pump (8) through the flow meter (7) and then through the perforated aeration pipe (6). The air volume is controlled by the flow meter, which can wash the surface of the membrane filament to reduce pollution, and can also provide the activated sludge microorganisms. oxygen. The liquid level in the reactor is controlled by a liquid level controller (3). The test inlet water is sent into the bioreactor by the inlet pump (2), and then the organic matter is removed through the catabolism of the microorganisms in the bioreactor, and finally the negative ...

Embodiment 2

[0030] The difference from Example 1 is that the carrier particles are ellipsoidal elastic fillers with multiple pairs of holes, and the filling ratio is 20% of the effective volume of the reactor. The parameters of the fluidized bed membrane bioreactor are: hydraulic retention time 13h; operating temperature: 10-30°C; PH: 6-8; gas volume: 0.3m3 / h, dissolved oxygen concentration: 0.2-2mg / L. The system uses intermittent suction to discharge water, pumping for 12 minutes, and stopping for 3 minutes. The membrane pore diameter is 0.2um, the surface area of the membrane is 0.2m2, and the membrane flux is 7.5L / (m2·h).

Embodiment 3

[0032]The difference from Examples 1 and 2 is that the carrier particles are ellipsoidal elastic fillers with multiple pairs of holes, and the filling ratio is 30% of the effective volume of the reactor. The parameters of the fluidized bed membrane bioreactor are: hydraulic Residence time 10h; operating temperature: 10-30°C; PH: 6-8; gas volume: 0.5m3 / h, dissolved oxygen concentration: 0.5-2.5mg / L. The system uses intermittent suction to discharge water, pumping for 12 minutes, and stopping for 3 minutes. The membrane pore diameter is 0.5um, the surface area of the membrane is 0.5m2, and the membrane flux is 10L / (m2·h).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com