Magnetization cracking device with stirring mechanism

A cracking device and stirring mechanism technology, applied in the direction of incinerators, combustion methods, lighting and heating equipment, etc., can solve the problem of comprehensive utilization of heat recovery, tail gas treatment methods, and undisclosed magnetization cracking. Uniform and effective technical solutions and other problems to achieve the effect of avoiding secondary pollution and fully effective magnetization cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

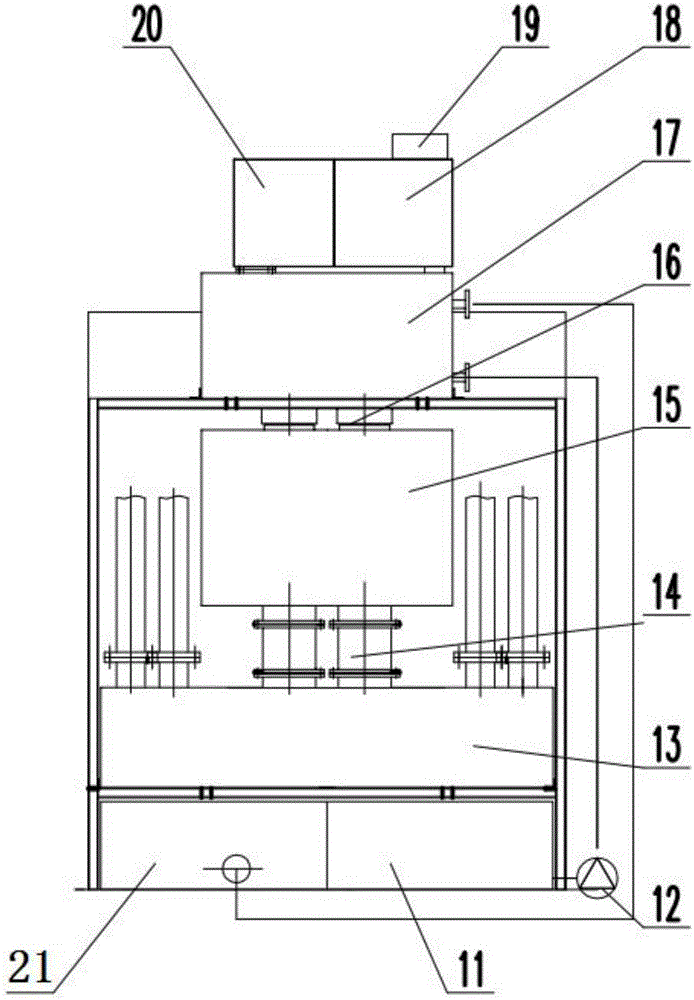

[0040]A tail gas treatment device and tail gas treatment method suitable for magnetization cracking of the present application will be described in more detail below in conjunction with the accompanying drawings.

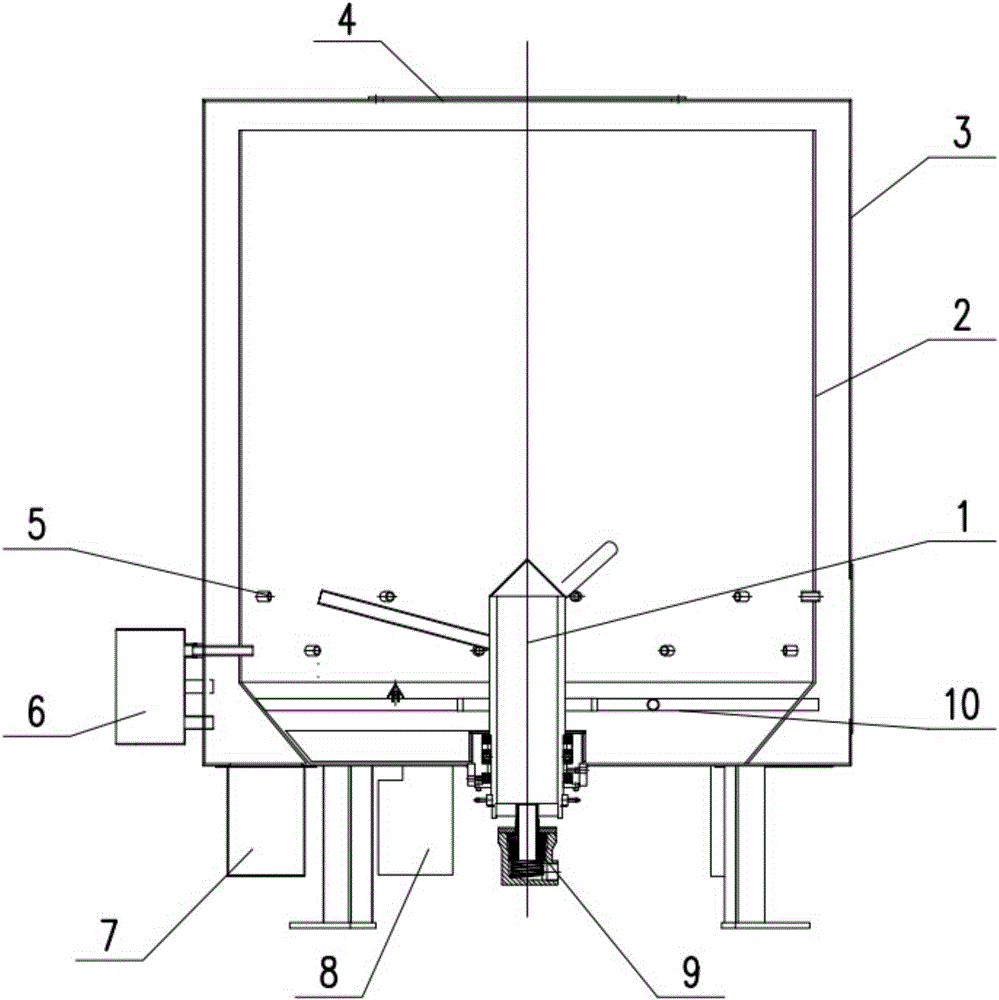

[0041] figure 1 It is a structural schematic diagram of a magnetic cracking device with a stirring mechanism in the present invention.

[0042] figure 2 It is a structural schematic diagram of a tail gas treatment device of a magnetic cracking device with a stirring mechanism in the present invention.

[0043] Such as figure 1 and figure 2 As shown, the present invention relates to a magnetization cracking device with a stirring mechanism, comprising a stirring shaft 1, an inner tank 2, an outer tank 3, a feeding port 4, an air inlet 5, a magnetization tank 6, a water tank 7, an ash tank 8, The rotary joint 9 and the furnace grate 10 can supply magnetized air to the cracking chamber in a balanced manner, and are equipped with a stirring device, which makes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com