Method for preparing 4A zeolite from gangue serving as raw material through two-step hydrothermal synthesis

A technology of hydrothermal synthesis and coal gangue, which is applied in the direction of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of weak operability, high cost, weak operability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

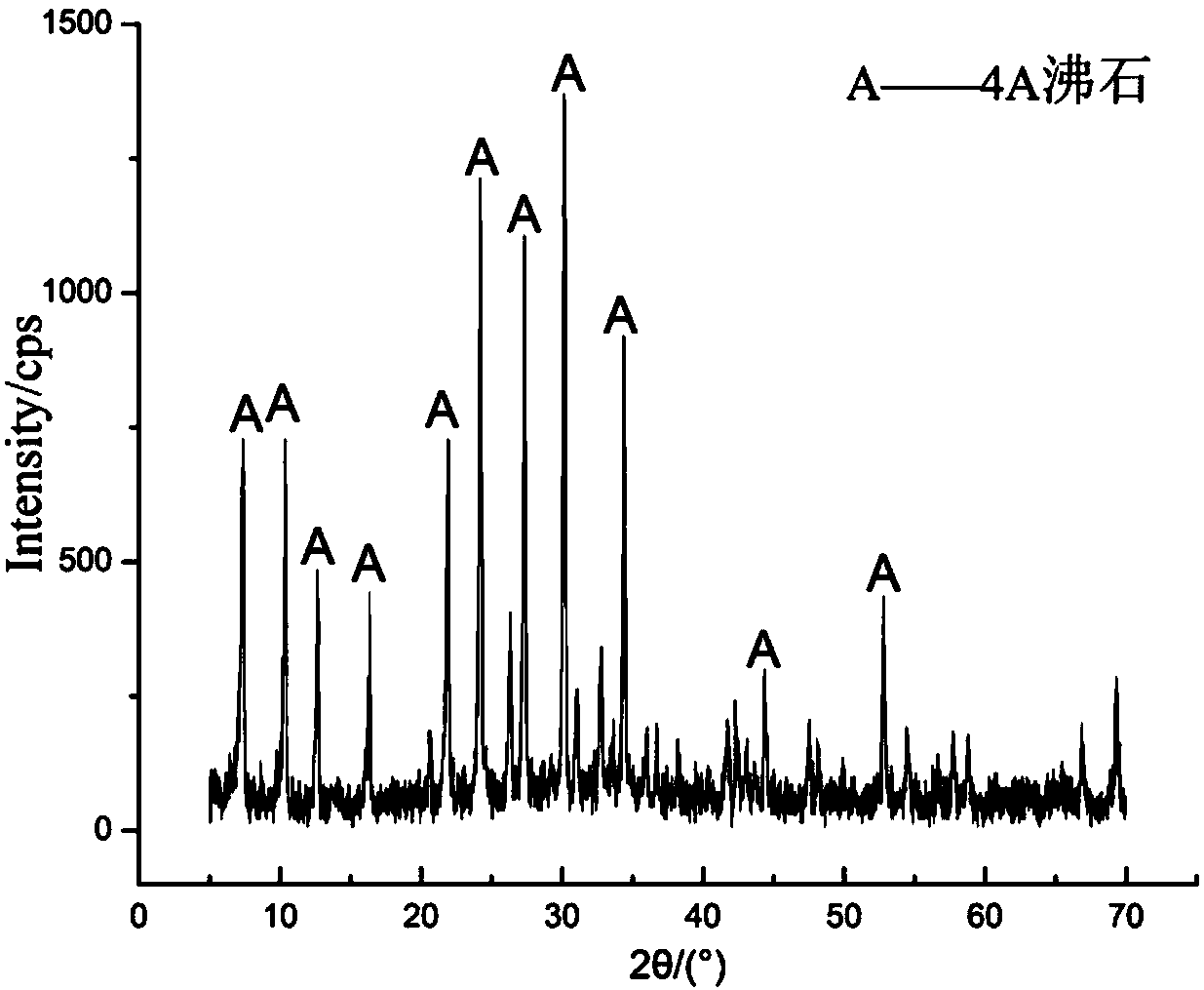

Embodiment 1

[0037] (1) After the coal gangue raw material is dried, crushed and ground, sieved to 300 mesh to obtain the coal gangue powder;

[0038] (2) Put the coal gangue powder in a muffle furnace for calcination at 750°C for 2 hours. After cooling, the mass ratio of sodium carbonate and gangue is 1.3. Mix the sodium carbonate and gangue powder evenly and place them in the muffle furnace at 830°C. Calcined at ℃ for 1 h to obtain a molten mixture;

[0039] (3) After cooling, add deionized water to the molten mixture at a liquid-solid ratio of 30mL / g, stir in a magnetic stirrer at 40°C for 1 hour, filter to obtain filter residue, and dry it in an oven;

[0040] (4) Mix the dried filter residue with sodium hydroxide solution, the concentration of sodium hydroxide solution is 3mol / L, the liquid-solid ratio is 20mL / g, stir at 60°C for 1h in a magnetic stirrer, filter to obtain the filtrate, Stir the filtrate at 60°C for 2 hours to age to obtain the precursor;

[0041] (5) Place the aging...

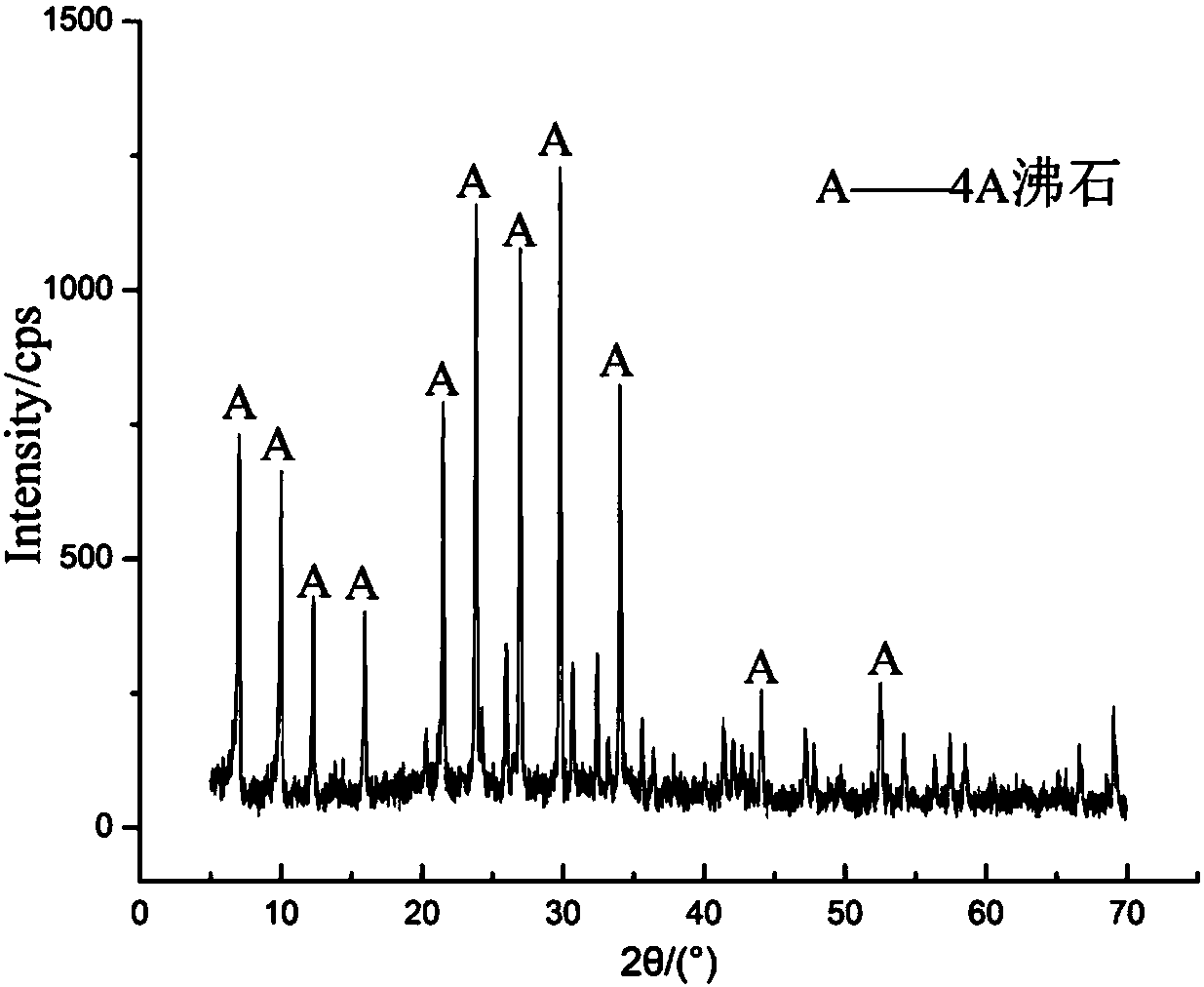

Embodiment 2

[0043] (1) After the coal gangue raw material is dried, crushed and ground, sieved to 300 mesh to obtain the coal gangue powder;

[0044] (2) Put the coal gangue powder in a muffle furnace for calcination at 700°C for 2 hours. After cooling, the mass ratio of sodium carbonate and gangue is 1.4. Mix the sodium carbonate and gangue powder evenly and place them in the muffle furnace at 830°C. Calcined at ℃ for 1 h to obtain a molten mixture;

[0045] (3) After cooling, add deionized water to the molten mixture at a liquid-solid ratio of 20mL / g, stir in a magnetic stirrer at 40°C for 1 hour, filter to obtain a filter residue, and dry it in an oven;

[0046] (4) Mix the dried filter residue with sodium hydroxide solution, the concentration of sodium hydroxide solution is 2.8mol / L, the liquid-solid ratio is 20mL / g, stir at 40°C for 1h in a magnetic stirrer, and filter to obtain the filtrate , the filtrate was aged at 70°C for 2h to obtain the precursor;

[0047] (5) Place the aging ...

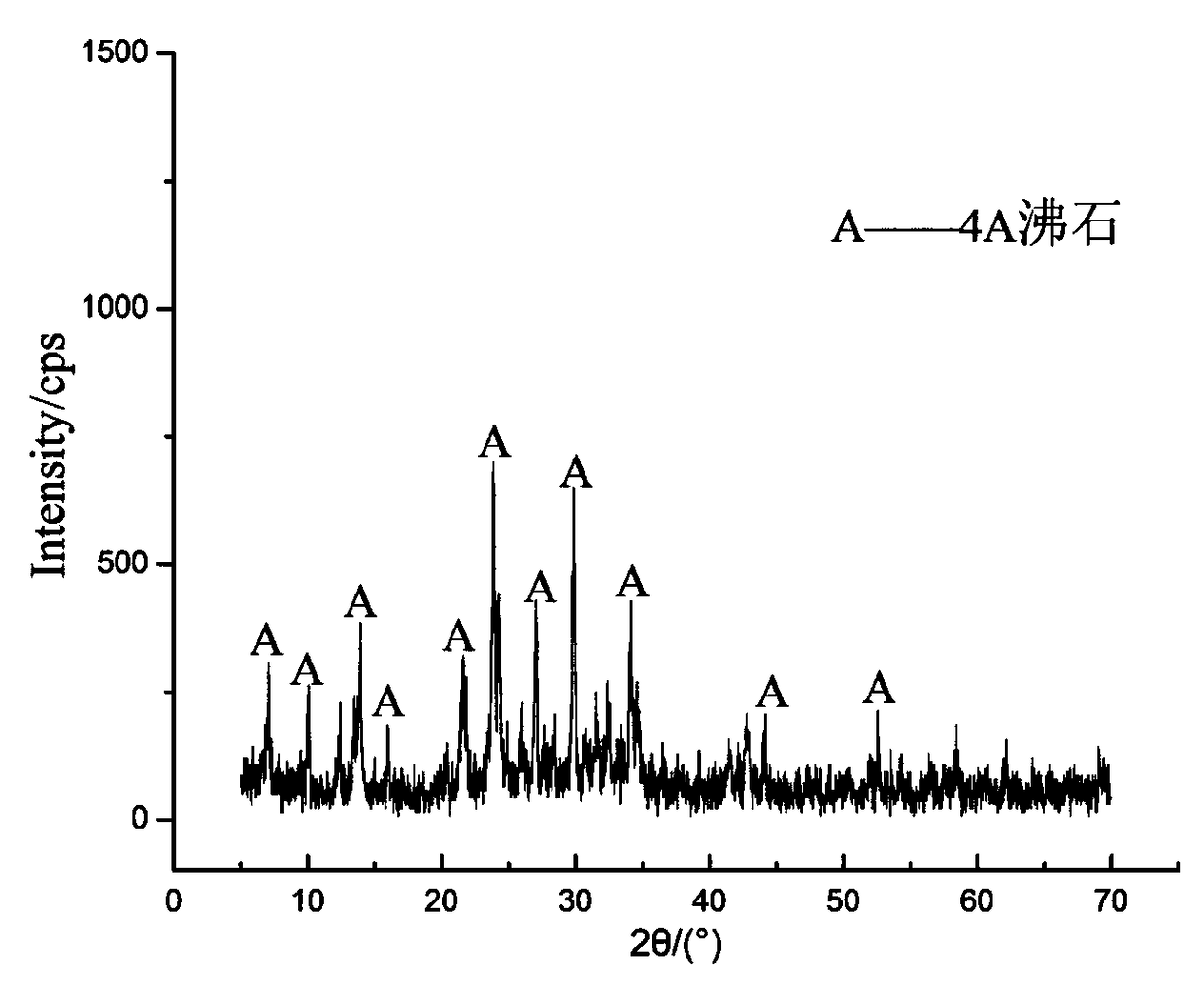

Embodiment 3

[0049] (1) After the coal gangue raw material is dried, crushed and ground, sieved to 300 mesh to obtain the coal gangue powder;

[0050] (2) Put the coal gangue powder in a muffle furnace for calcination at 800°C for 2 hours. After cooling, the mass ratio of sodium carbonate and gangue is 1.5. Mix the sodium carbonate and coal gangue powder evenly and place them in the muffle furnace at 830°C. Calcined at ℃ for 2h to obtain a molten mixture;

[0051] (3) After cooling, add deionized water to the molten mixture at a liquid-solid ratio of 50mL / g, stir in a magnetic stirrer at 40°C for 1 hour, filter to obtain filter residue, and dry it in an oven;

[0052] (4) Mix the dried filter residue with sodium hydroxide solution, the concentration of sodium hydroxide solution is 2.5mol / L, the liquid-solid ratio is 20mL / g, stir at 50°C for 1h in a magnetic stirrer, and filter to obtain the filtrate , the filtrate was aged at 65°C for 2h to obtain the precursor;

[0053] (5) Place the ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com