Mobile small electroplating wastewater treatment device

A technology for electroplating wastewater and treatment device, which is applied in the fields of metallurgical wastewater treatment, sterilization/microdynamic water/sewage treatment, water/sewage treatment, etc., and can solve the problems of low applicability, inconvenient movement, and unsuitable for electroplating wastewater treatment. , to achieve the effect of strong practicability, improved filtration and purification effect, high social use value and application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

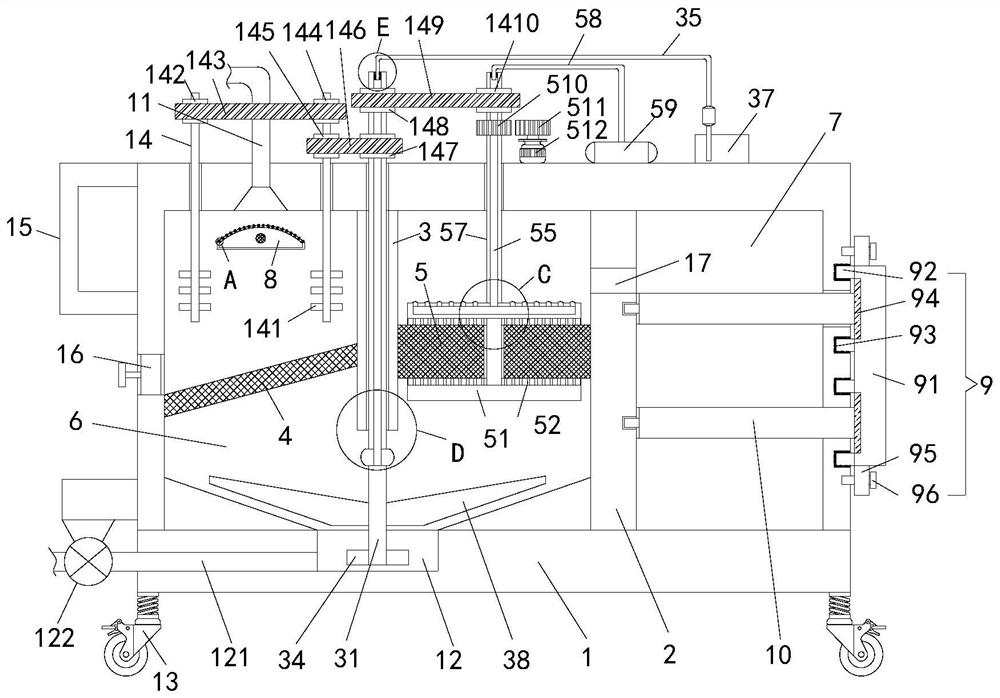

[0053] refer to Figure 1-10 , a mobile small electroplating wastewater treatment device, comprising a body shell 1 and a wall 2, the wall 2 divides the inside of the body shell 1 into a mixed sedimentation chamber 6 and a purification chamber 7, and the inner top wall of the mixed sedimentation chamber 6 is vertical A barrier plate 3 is provided, a large particle filter screen 4 is obliquely arranged between the side wall of the barrier plate 3 and the side wall of the mixed sedimentation chamber 6, and a filter screen 4 is arranged between the other side wall of the barrier plate 3 and the side wall of the mixed sedimentation chamber 6 Molecular sieve 5;

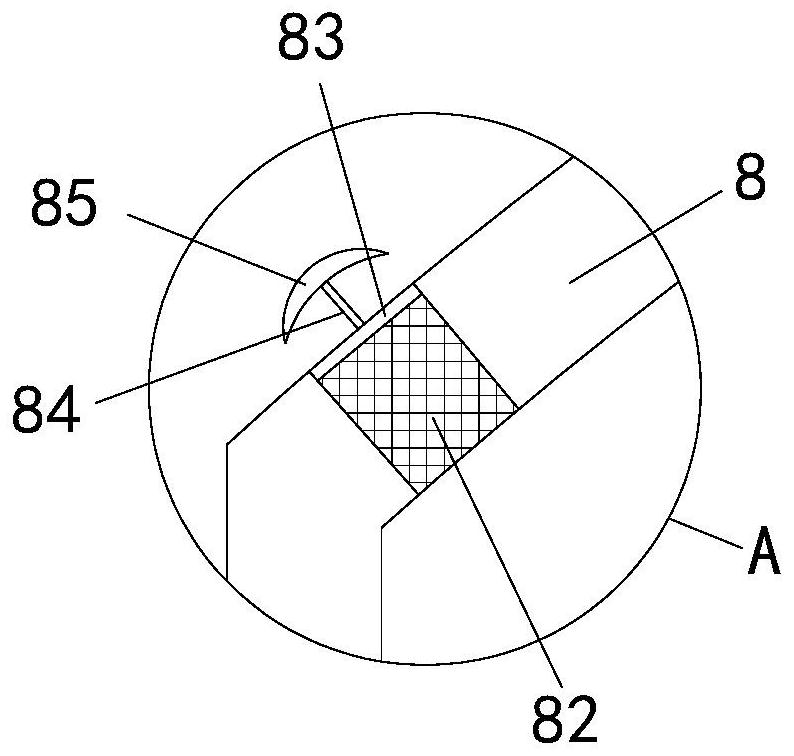

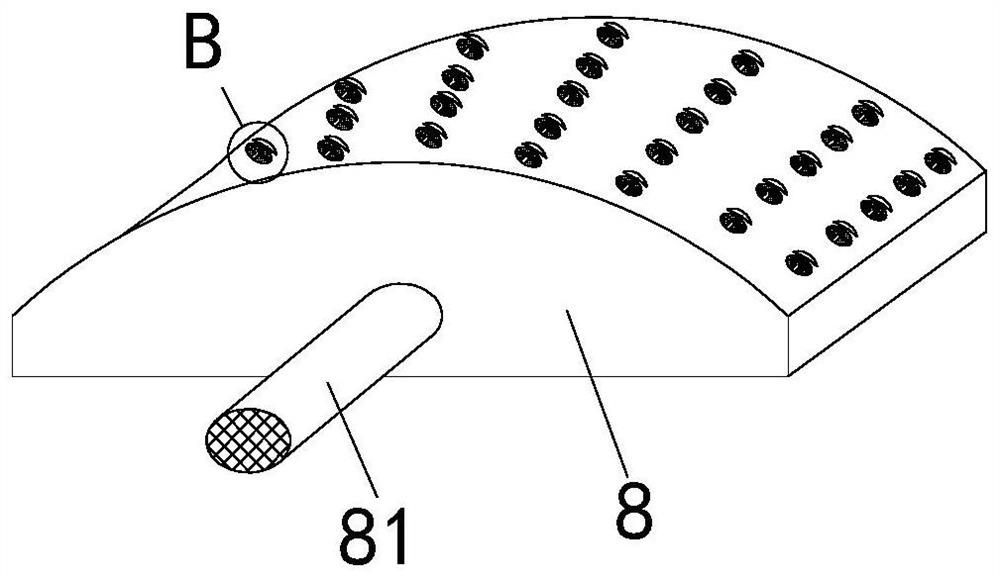

[0054] The upper end side of the mixed sedimentation chamber 6 is connected with a sewage inlet 11, and an arc-shaped medicine box 8 is arranged directly below the sewage inlet 11. The outer wall side of the arc-shaped medicine box 8 is connected with a medicine inlet pipe 81, and the medicine inlet pipe 81 runs through th...

Embodiment 2

[0069] refer to Figure 1-10 The difference between this embodiment and Embodiment 1 is that the inner wall of the first connecting shaft 31 is provided with a communication pipe 32, the bottom of the communication pipe 32 is symmetrically connected with spray heads 33 on both sides, and the upper port of the communication pipe 32 is plugged with a liquid inlet. The first bearing 36 is sleeved on the outer wall of the connection between the pipe 35 and the liquid inlet pipe 35 and the communication pipe 32, and the setting of the first bearing 36 does not affect the installation and fixation of the liquid inlet pipe 35;

[0070] The outward extension end of the liquid inlet pipe 35 is provided with a disinfection box 37, and a booster pump is installed on the pipeline of the liquid inlet pipe 35. Under the boosting action of the booster pump, the disinfectant in the disinfection box 37 enters through the liquid inlet pipe 35. The communication pipe 32 is sprayed to the mixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com