Segment treatment method for fluorine-containing heavy metal wastewater

A treatment method and heavy metal technology, which is applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high transportation and processing costs, difficult treatment and disposal, and increased cement manufacturing costs and other problems, to achieve the effect of improving the burnability, shortening the firing time, and improving the quality of clinker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

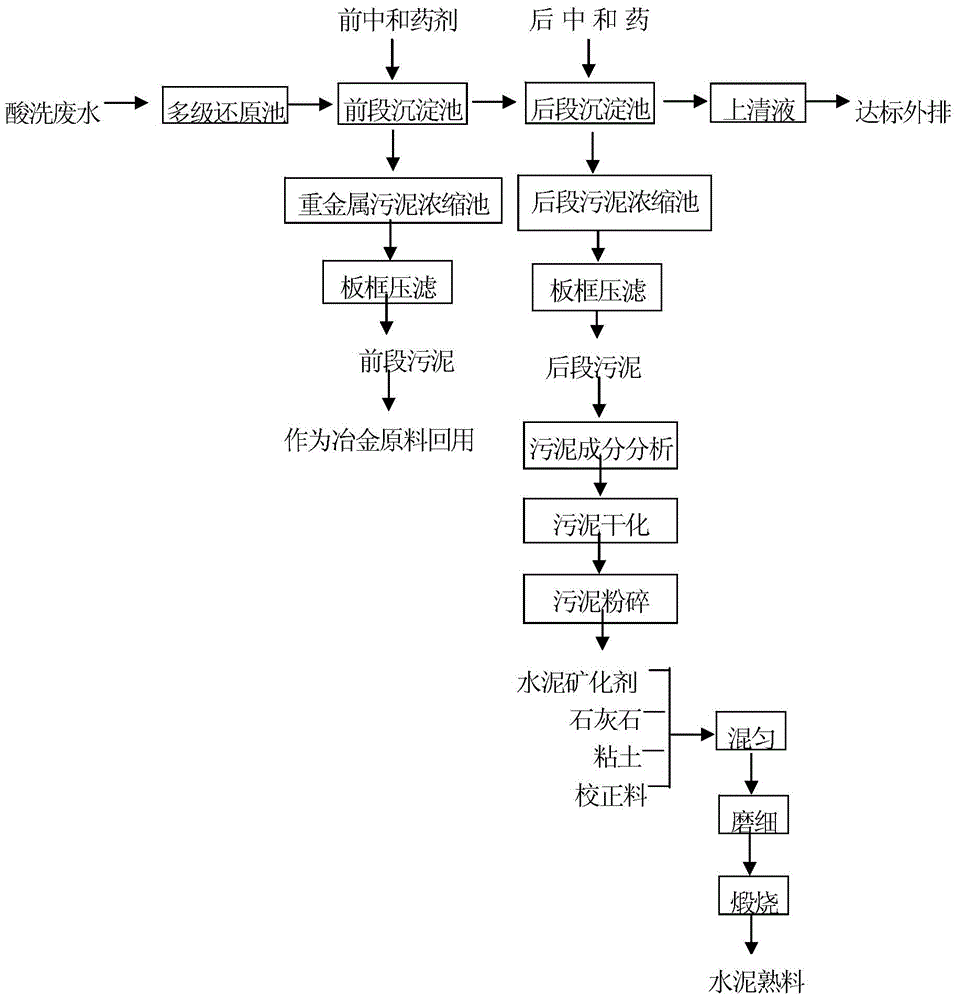

[0053] As shown in Figure 1, this is a process flow diagram of the present invention utilizing stainless steel cold rolling pickling wastewater to prepare cement mineralizer and its application method.

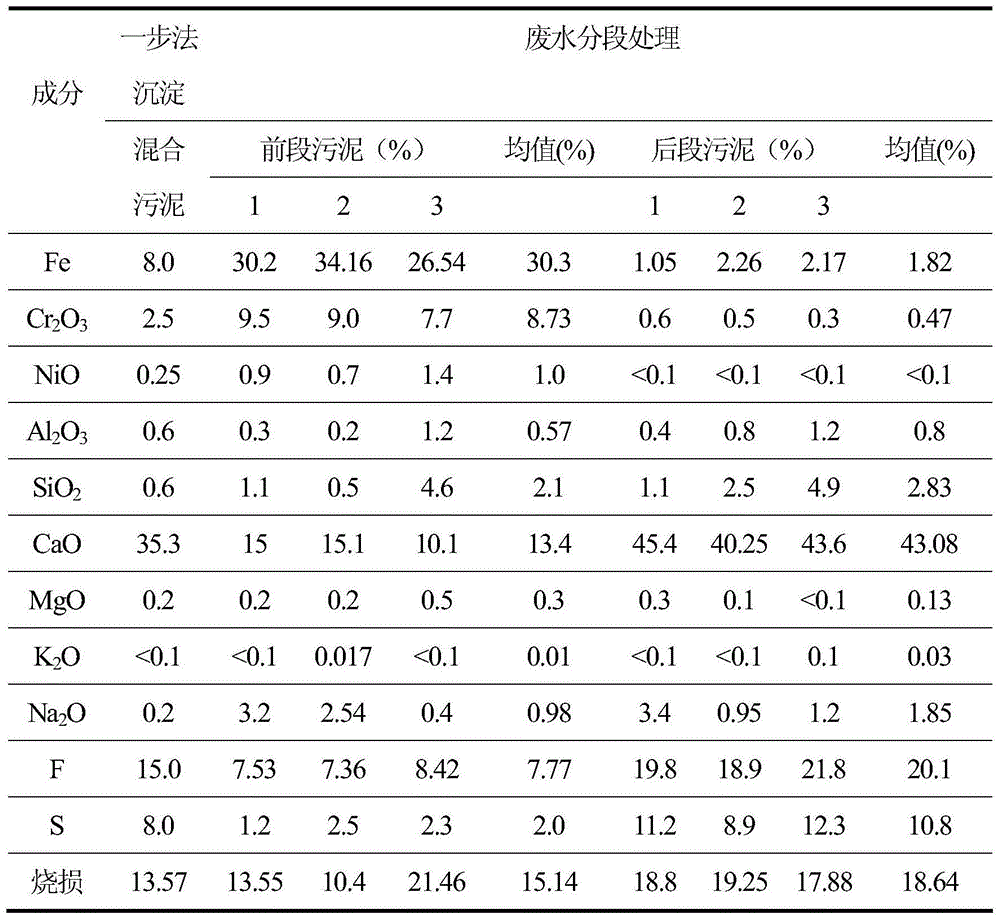

[0054] The method of the invention is applied to a cold rolling pickling waste water treatment station of a stainless steel enterprise. The daily wastewater treatment capacity of this treatment station is 100m 3 / h, the original process route is the traditional Ca(OH) 2 The one-step excessive dosing method produces 50t / d of mixed sludge that is difficult to use. After adopting the two-stage sedimentation process route of the present invention, the total sludge output is 42t / d, which corresponds to a reduction of 8t / d.

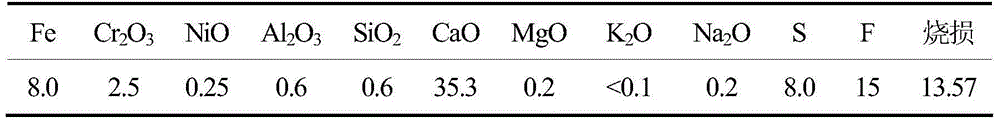

[0055] According to the process of the present invention, in the multi-stage chemical reduction treatment of stainless steel cold rolling pickling wastewater, more than 99% of Cr 6+ reduced to Cr 3+ After that, it enters the staged treatment process. In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com