Method for preparing high-ferric Alite-calcium barium sulphoaluminate cement by using red mud and barium mud

A technology of barium calcium sulfoaluminate and cement, which is applied in the direction of cement production, etc. It can solve the problems of reducing the content of tricalcium silicate, reducing costs, and high energy consumption, and achieves the effects of low firing temperature, cost reduction, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

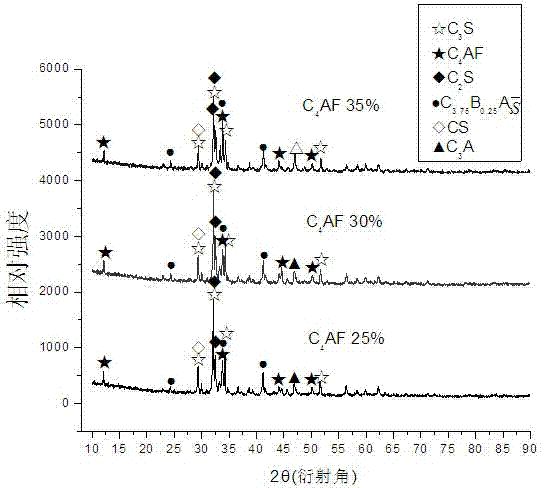

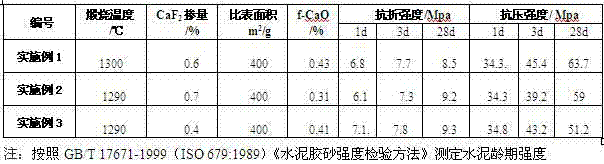

[0024] (1) The weight percentage of the mineral phase composition of the design cement clinker is: C 3.75 B 0.25 A 3 6%, C 2 S: 19%, C 3 S 42%, C 4 AF 25% and C 3 A 8%.

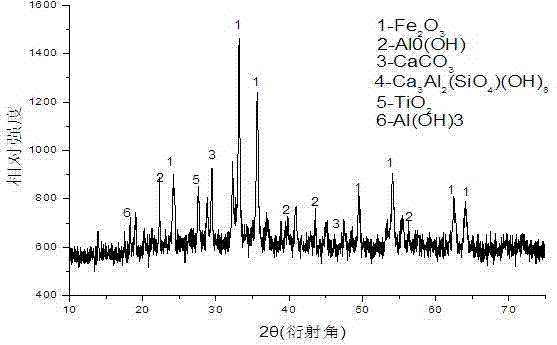

[0025] (2) Using the mathematical calculation software mathematica5.0 that comes with Excel, the weight percentage of raw materials is calculated as follows: clay 15.66%, red mud 12.53%, limestone 66.15%, gypsum 3.6%, barium mud 0.33%, bauxite 1.15% and fluorite 0.58%.

[0026] (3) Crumble and homogenize the raw materials calculated in step (2), and dry them separately until the moisture content is less than 1%; the ball mill grinds through a 200-mesh sieve and the residue is less than 5%, so that the ingredients are uniform, and the powder is ground until raw until the ingredients are mixed.

[0027] (4) Make the raw material mixed in step (3) into a round cake-shaped sample with a radius of 5 cm and a thickness of 2 cm. The calcination temperature is 1300 Sintering under the lower conditions for ...

Embodiment 2

[0031] (1) The weight percentage of the mineral phase composition of the design cement clinker is: C 3.75 B 0.25 A 3 6%, C 2 S: 19%, C 3 S 37%, C 4 AF 30% and C 3 A 8%.

[0032] (2) Using the mathematical calculation software mathematica5.0 that comes with Excel, the weight percentage of raw materials is calculated as follows: clay 13.79%, red mud 16.4%, limestone 63.86%, gypsum 3.57%, barium mud 0.33%, bauxite 1.47% and fluorite 0.58%.

[0033] (3) Crumble and homogenize the raw materials calculated in step (2), and dry them separately until the moisture content is less than 1%; the ball mill grinds through a 200-mesh sieve and the residue is less than 5%, so that the ingredients are uniform, and the powder is ground until raw until the ingredients are mixed.

[0034] (4) Make the raw material mixed in step (3) into a round cake-shaped sample with a radius of 5 cm and a thickness of 2 cm. The calcination temperature is 1290 Sintering under the same conditions for...

Embodiment 3

[0038] (1) The weight percentage of the mineral phase composition of the design cement clinker is: C 3.75 B 0.25 A 3 6%, C 2 S: 19%, C 3 S 32%, C 4 AF 35% and C 3 A 8%.

[0039] (2) Using the mathematical calculation software mathematica5.0 that comes with Excel, the weight percentage of raw materials is calculated as follows: clay 11.95%, red mud 20.34%, limestone 61.64%, gypsum 3.55%, barium mud 0.33%, bauxite 1.8% and fluorite 0.39%.

[0040] (3) Crumble and homogenize the raw materials calculated in step (2), and dry them separately until the moisture content is less than 1%; the ball mill grinds through a 200-mesh sieve and the residue is less than 5%, so that the ingredients are uniform, and the powder is ground until raw until the ingredients are mixed.

[0041] (4) Make the raw material mixed in step (3) into a round cake-shaped sample with a radius of 5 cm and a thickness of 2 cm. The calcination temperature is 1290 Sintering under the same conditions for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com