Method for producing high-strength clinker from high-magnesium limestone

A limestone and high-magnesium technology, applied in cement production and other directions, can solve the problems of tight supply of low-magnesium and high-calcium limestone, unguaranteed cement strength, frequent failure of kiln production process, etc., so as to improve flammability and reduce heat Power consumption and power consumption, the effect of energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

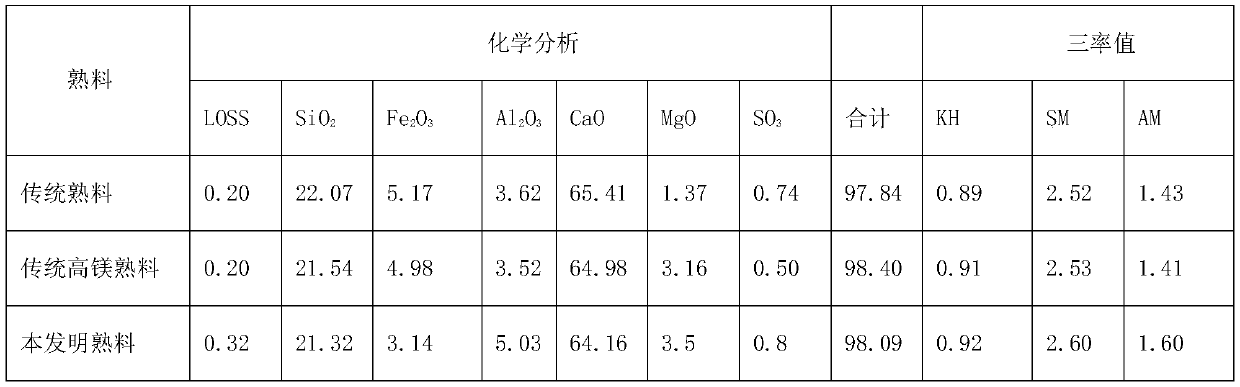

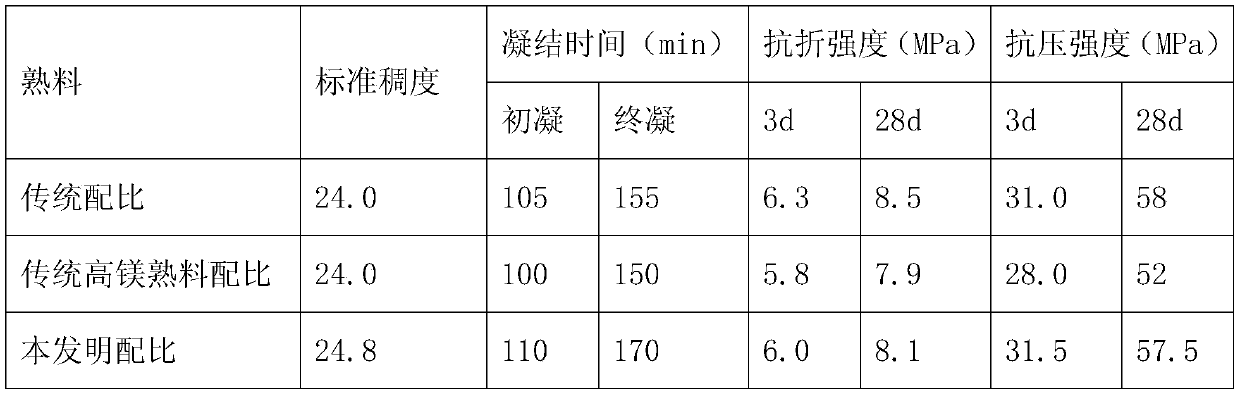

Embodiment 1

[0018] A method for producing high-strength clinker from high-magnesium limestone. The raw materials and proportions are as follows: sulfate slag 7%, high-magnesium limestone 8%, low-magnesium limestone 76%, shale 4%, sandstone 2%, and coal gangue 3%.

Embodiment 2

[0020] A method for producing high-strength clinker from high-magnesium limestone. The raw materials and proportions are as follows: sulfate slag 7%, high-magnesium limestone 10%, low-magnesium limestone 75%, shale 2%, sandstone 4%, and coal gangue 2%.

Embodiment 3

[0022] A method for producing high-strength clinker from high-magnesium limestone. The raw materials and proportions are as follows: sulfate slag 7%, high-magnesium limestone 15%, low-magnesium limestone 70%, shale 2%, sandstone 3%, coal gangue 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com