Cement clinker preparation method using converter steel slag to correct iron quality

A converter steel slag and cement clinker technology, which is applied in clinker production, cement production, etc., can solve the problems of insufficient steel slag seed crystal effect, insufficient grinding fineness, and reduced grinding efficiency, etc., to improve flammability , Improve efficiency and reduce heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

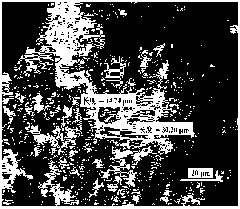

[0031] Add 1.9wt% of the converter steel slag after the two-stage step grinding, 80wt% of limestone, 15.2wt% of shale, and 2.9wt% of sandstone to the raw mill and mix evenly, and grind to conventional raw meal powder. The fineness of the milled converter steel slag and cement raw meal mixture is put into the kiln for calcination at a temperature of 1400°C to obtain the corresponding cement clinker.

[0032] After testing, the f-CaO of cement clinker is 0.52%; desulfurized gypsum is added based on 2.5% sulfur trioxide by weight. The net cement clinker strength test results are as follows: 3d strength is 62.9MPa, 28d The strength is 74.7MPa; the quality of cement clinker is uniform, there is no local steel slag enrichment phenomenon, and its microstructure is shown figure 1 .

Embodiment 2

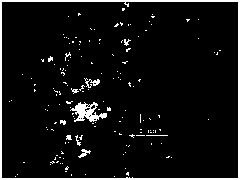

[0034] Add 3wt% of the converter steel slag after the second step grinding, 79wt% of limestone, 15wt% of shale, and 3wt% of sandstone to the raw mill to mix evenly, and grind to the fineness of conventional raw meal. ; The mixed milled converter steel slag and cement raw meal mixture is put into the kiln for calcination at a temperature of 1400 ℃ to obtain the corresponding cement clinker.

[0035] After testing, the f-CaO of cement clinker is 0.41%; desulfurization gypsum is added based on 2.5% sulfur trioxide by weight. The net cement clinker strength test results are as follows: 3d strength is 63.8MPa, 28d The strength is 77.3MPa; the quality of cement clinker is uniform, there is no local steel slag enrichment phenomenon, and its microstructure can be seen figure 2 .

Embodiment 3

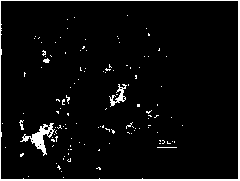

[0037] Add 3.5wt% of the converter steel slag after the two-stage step grinding, 77.8wt% of limestone, 17.1wt% of shale, and 1.6wt% of sandstone into the raw mill to mix evenly, and grind to conventional raw meal. The fineness of the powder; the mixed milled converter steel slag and cement raw meal mixture is put into the kiln for calcination at a temperature of 1400°C to obtain the corresponding cement clinker.

[0038] After testing, the f-CaO of cement clinker is 0.39%; desulfurized gypsum is added based on 2.5% sulfur trioxide by weight. The net cement clinker strength test results are as follows: 3d strength is 62.7MPa, 28d The strength is 77.4MPa; the quality of cement clinker is uniform, there is no local steel slag enrichment phenomenon, and its microstructure is visible image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com