Method for synergistically treating heavy metal sludge in cement production

A heavy metal sludge and co-processing technology, applied in the direction of cement production, etc., can solve the problems of ineffective use of tail gas waste heat, poor applicability, high energy consumption in the production process, etc., to achieve optimal utilization of resources and environmental protection, improve fluidity and stability Sexuality and calcination operation are more controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

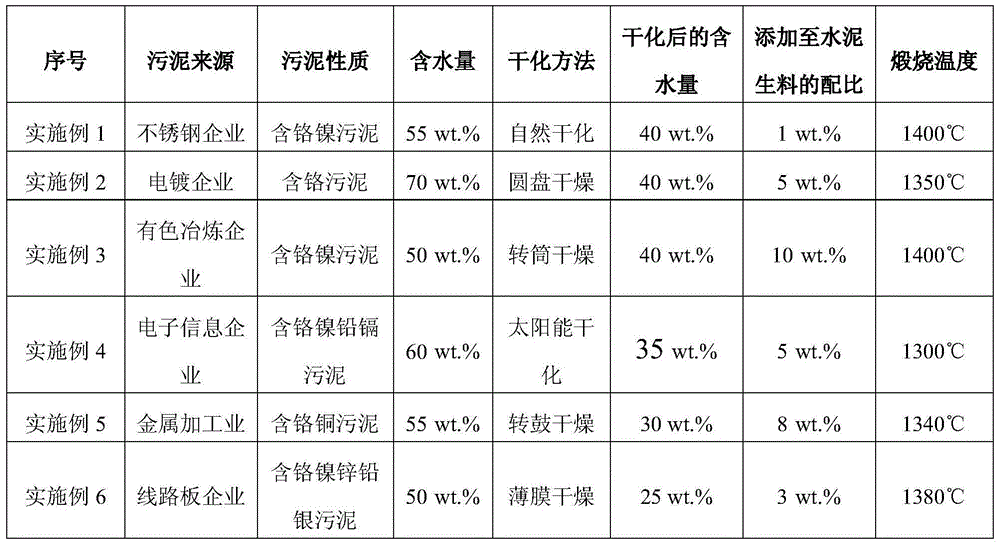

[0039] The method of co-processing heavy metal sludge in cement production was applied to three different heavy metal sludge treatments, and the steps included:

[0040] (1) Naturally dry or use drying equipment to dry and pretreat the heavy metal sludge (with a water content of 50-70wt%) from three different production enterprises to reduce the water content to below 40wt%;

[0041] (2) Add the dry pretreated heavy metal sludge to the cement raw material, and the addition ratio accounts for 1-10wt% of the cement raw material. The heavy metal sludge and the cement raw material are fully mixed in the vertical mill, and the mixture is finely ground After that, it is made into cement raw meal;

[0042] (3) After the cement raw meal is homogenized, it is sent to the calcination system to be fired into cement clinker, and the waste heat and waste gas generated after calcination are passed into the vertical mill in step (2) to dry the cement raw meal.

[0043] It should be noted th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com