Cement clinker and preparation method and application thereof

A technology of cement clinker and cement raw meal, which is applied in the direction of cement production and clinker production, etc. It can solve the problems of not being able to meet the needs of large-scale construction projects, the early strength decline of composite cement, and the poor stability of composite cement, so as to shorten the clinker. Effects of forming time, improving burnability, and shortening setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

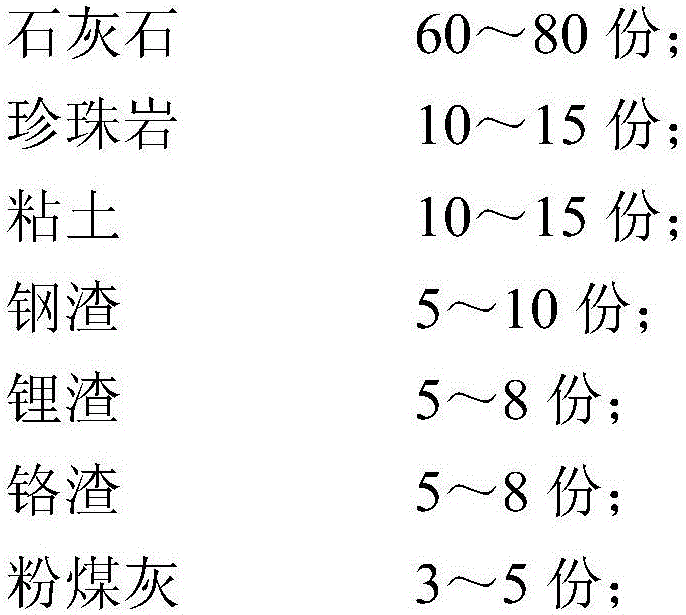

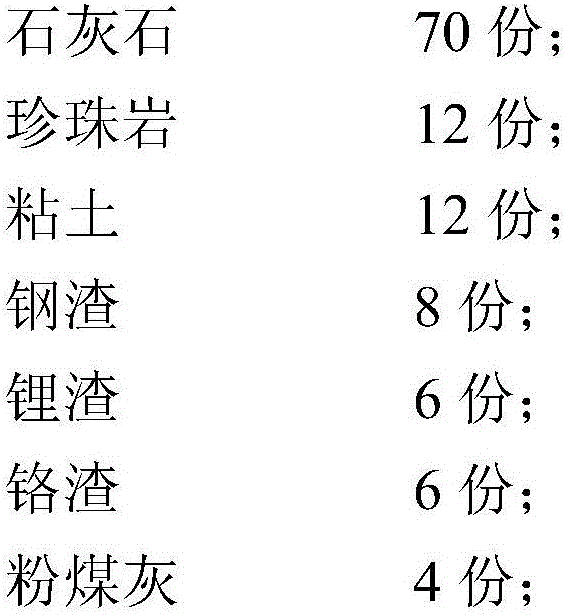

[0041] A kind of cement clinker, is prepared by the following raw material components by mass parts:

[0042]

[0043] The preparation method of above-mentioned cement clinker, comprises the steps:

[0044] (1) the limestone of the raw material component 70 mass parts of above-mentioned cement clinker, the perlite of 12 mass parts, the clay of 12 mass parts, the steel slag of 8 mass parts, the lithium slag of 6 mass parts, the chromium of 6 mass parts The slag and 4 parts by mass of fly ash were respectively crushed, ground, and uniformly mixed in a raw meal homogenization storehouse to obtain raw cement meal, wherein the fineness of the raw meal cement was 80 μm and the sieve residue of a square hole sieve was 6%;

[0045] (2) Calcining the raw cement meal prepared in step (1) at 1250° C. for 40 minutes to obtain cement clinker.

[0046] A preparation method for cement, comprising the steps of:

[0047] Mix the above cement clinker with gypsum, grind until the average pa...

Embodiment 2

[0049] A kind of cement clinker, is prepared by the following raw material components by mass parts:

[0050]

[0051] The preparation method of above-mentioned cement clinker, comprises the steps:

[0052] (1) the limestone of the raw material component 80 mass parts of above-mentioned cement clinker, the perlite of 10 mass parts, the clay of 15 mass parts, the steel slag of 10 mass parts, the lithium slag of 5 mass parts, the chromium of 5 mass parts The slag and 3 parts by mass of fly ash are crushed and ground respectively, and mixed evenly in the raw meal homogenization storehouse to obtain cement raw meal, wherein the fineness of the cement raw meal is 80 μm and the sieve allowance of the square hole sieve is 10% ;

[0053] (2) Calcining the raw cement meal prepared in step (1) at 1200° C. for 60 minutes to obtain cement clinker.

[0054] A preparation method for cement, comprising the steps of:

[0055] Mix the above cement clinker with gypsum, grind until the ave...

Embodiment 3

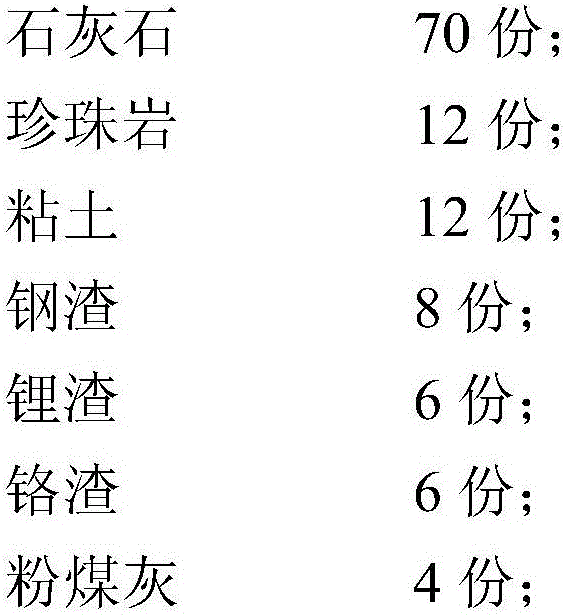

[0057] A kind of cement clinker, is prepared by the following raw material components by mass parts:

[0058]

[0059] The preparation method of above-mentioned cement clinker, comprises the steps:

[0060] (1) the limestone of the raw material component 60 mass parts of above-mentioned cement clinker, the perlite of 15 mass parts, the clay of 10 mass parts, the steel slag of 5 mass parts, the lithium slag of 8 mass parts, the chromium of 8 mass parts The slag and 5 parts by mass of fly ash are respectively crushed, ground, and mixed evenly in the raw meal homogenization storehouse to obtain cement raw meal, wherein the fineness of the cement raw meal is 80 μm and the sieve allowance of the square hole sieve is 5%. ;

[0061] (2) Calcining the raw cement meal prepared in step (1) at 1350° C. for 30 minutes to obtain cement clinker.

[0062] A preparation method for cement, comprising the steps of:

[0063] The above cement clinker is mixed with gypsum, and ground until t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com