Preparation method for Portland cement with iron tailings

A technology of Portland cement and iron tailings, which is applied in the field of building materials to achieve the effect of improving utilization rate and significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

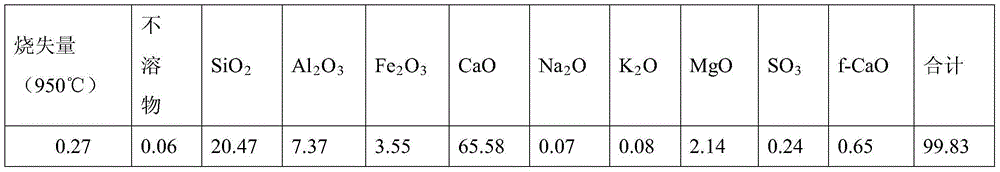

[0024] The preparation method of the iron tailings Portland cement provided in this embodiment is as follows: (1) Weigh 65 g of calcium oxide, 17 g of silicon oxide, 10 g of iron tailings, 4 g of alumina and 2 g of ferric oxide, and mix them evenly Afterwards, the raw materials are put into a vibrating mill for grinding for 2 minutes, and the remaining amount of the finely ground material through a 200-mesh sieve is not more than 8%, and the mixed raw meal is prepared after fine grinding.

[0025] The iron tailings are waste slag after magnetic separation in the concentrator. The chemical composition and the mass percentage of each composition are as follows: CaO10-20%, SiO 2 25~70%, Al 2 O 3 3~10%, TFe 2 O 3 10-25%, MgO 2 O+K 2 O 2 O 5 <2%, S <3%.

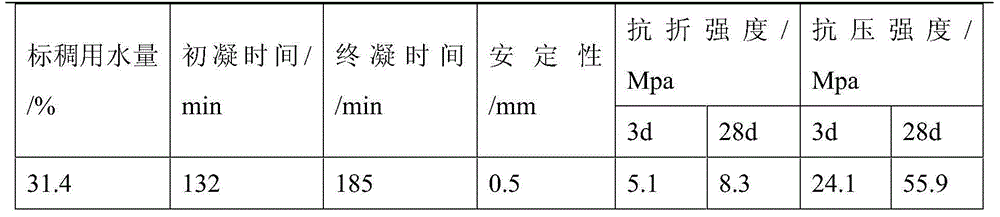

[0026] (2) The finely ground raw materials are calcined in a high temperature furnace for 30 to 90 minutes and then discharged out of the kiln. The calcined raw materials are quenched in the air and artificially assisted to accelerate t...

Embodiment 2

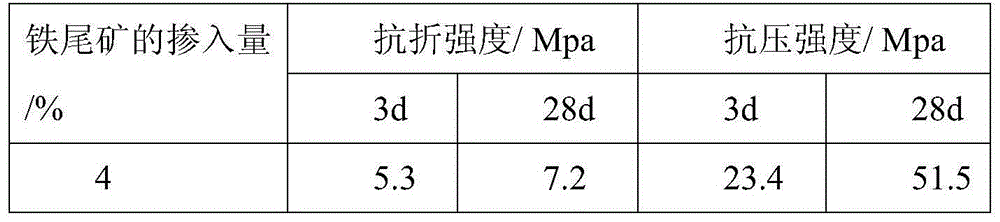

[0038] The preparation method of the iron tailings Portland cement provided in this example is as follows: (1) Weigh 62g calcium oxide, 14g silica, 19g iron tailings, and 5g alumina, mix them evenly, put the raw materials into vibration Grinding is carried out for 4 minutes in the mill, the remainder of the finely ground material passing through a 200-mesh sieve does not exceed 8%, and the mixed raw meal is prepared after fine grinding.

[0039] The iron tailings are waste slag after magnetic separation in the concentrator. The chemical composition and mass percentage of each composition are as follows: CaO10-20%, SiO 2 25~70%, Al 2 O 3 3~10%, TFe 2 O 3 10-25%, MgO 2 O+K 2 O 2 O 5 <2%, S <3%.

[0040] (2) The finely ground raw materials are calcined in a high temperature furnace for 30 to 90 minutes and then discharged out of the kiln. The calcined raw materials are quenched in the air and artificially assisted to accelerate the cooling. The calcining temperature is 1350°C to 1450°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com