Agricultural low-temperature phase change heat storage material and preparation method thereof

A heat storage material and low-temperature phase change technology, applied in heat exchange materials, botany equipment and methods, agricultural machinery and equipment, etc., can solve the problems of high phase change temperature, low phase change latent heat, poor stability, etc., and achieve phase change The effect of high latent heat, weakened hydration, and lowered melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Put the test tube containing 10g of disodium hydrogen phosphate dodecahydrate and 1g of water into a water bath with a constant temperature of 80°C to heat and shake until all the disodium hydrogen phosphate dodecahydrate dissolves to obtain an aqueous solution of disodium hydrogen phosphate; Add 0.5g potassium chloride (KCl), 0.5g ammonium chloride (NH 4 Cl), heated to 70°C to dissolve, cooled to 30°C, sieved and filtered, and the undersieve was dried in a blast oven at 45°C to obtain an agricultural low-temperature phase change heat storage material.

[0039] After testing, the above-mentioned agricultural low-temperature thermal storage phase change material has a phase transition temperature of 34°C, an undercooling degree of 1.6°C, and a latent heat of phase transition of 160J / g. After 1,000 heat storage and heat release cycles, the thermal stability is good.

Embodiment 2

[0041] Put the test tube containing 25g of disodium hydrogen phosphate dodecahydrate, 20g of disodium hydrogen phosphate hexahydrate and 10g of water into a water bath with a constant temperature of 60°C to heat and shake until the disodium hydrogen phosphate crystalline compound is completely dissolved to obtain dihydrogen phosphate Sodium aqueous solution; add 2.5g potassium chloride (KCl), 2.5g ammonium chloride (NH 4 Cl), heated to 50°C to dissolve, cooled to 25°C, sieved and filtered, and the undersieve was dried in a blast oven at 35°C to obtain an agricultural low-temperature phase change heat storage material.

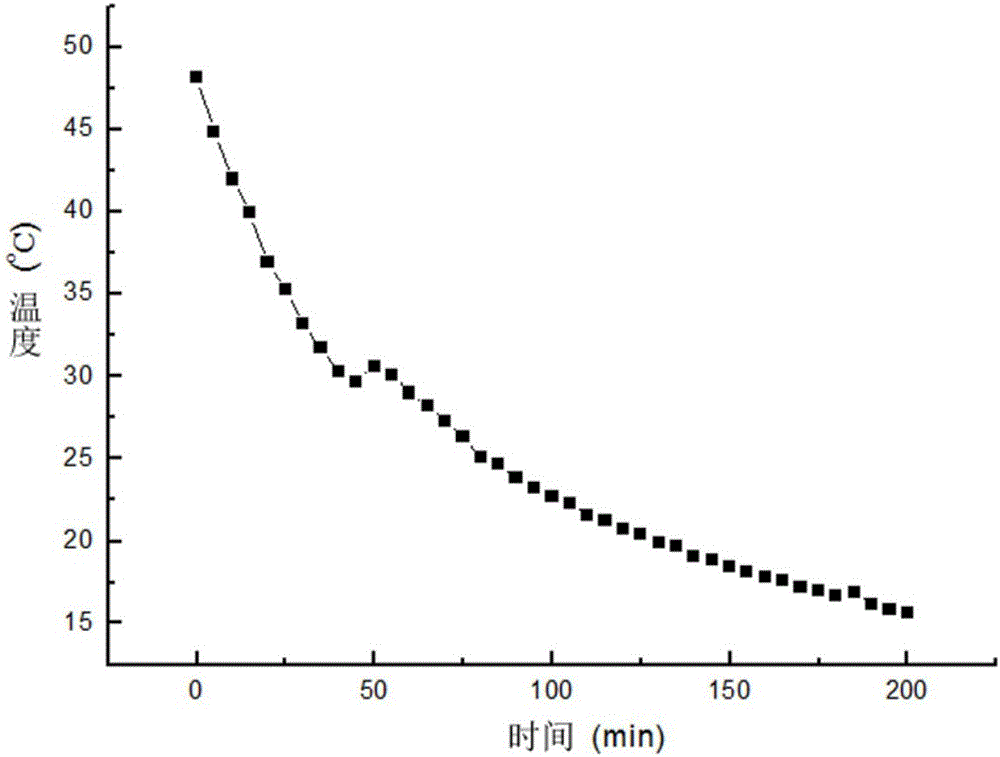

[0042] figure 1 It is the step-cooling curve of the above-mentioned agricultural low-temperature phase-change heat storage material. After testing, the phase-change temperature of the above-mentioned agricultural low-temperature heat-storage phase-change material is 30.4°C, the degree of subcooling is 0.9°C, and the latent heat of phase change is 190J / g. Heat st...

Embodiment 3

[0044] Put the test tube containing 55g disodium hydrogen phosphate dodecahydrate and 22g water into a water bath with a constant temperature of 50°C to heat and shake until disodium hydrogen phosphate dodecahydrate is completely dissolved to obtain an aqueous solution of disodium hydrogen phosphate; Add 3.9g potassium chloride (KCl), 3.9g ammonium chloride (NH 4 Cl), heated to 30°C to dissolve, cooled to 20°C, sieved and filtered, and the undersieve was dried in a blast oven at 30°C to obtain an agricultural low-temperature phase change heat storage material.

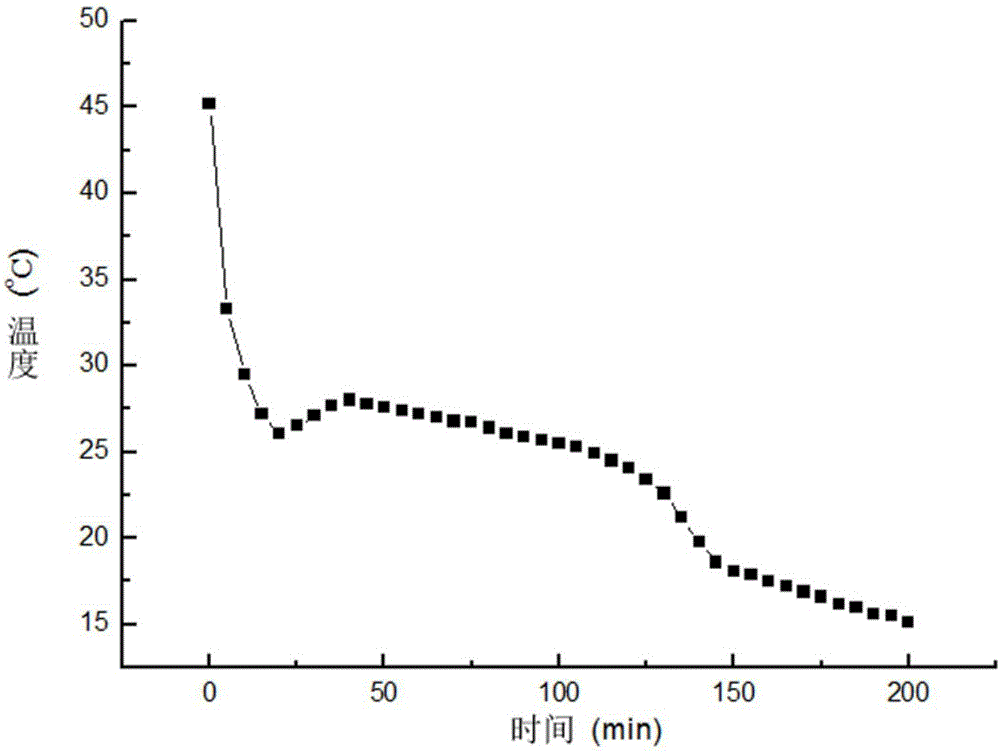

[0045] figure 2 It is the step-cooling curve of the above-mentioned agricultural low-temperature phase-change thermal storage material. After testing, the above-mentioned agricultural low-temperature thermal storage phase-change material has a phase transition temperature of 28°C, an undercooling degree of 2°C, and a latent heat of phase change of 200J / g. After 1000 heat storage and heat release cycles, the thermal s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com