Glazed ceramic tile and preparation method thereof

A technology for ceramic tiles and glazed surfaces, applied in the field of glazed ceramic tiles and its preparation, can solve the problems of less sludge consumption, poor green body strength, and low yield, and achieve an increase in firing temperature range, a reduction in sintering temperature, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

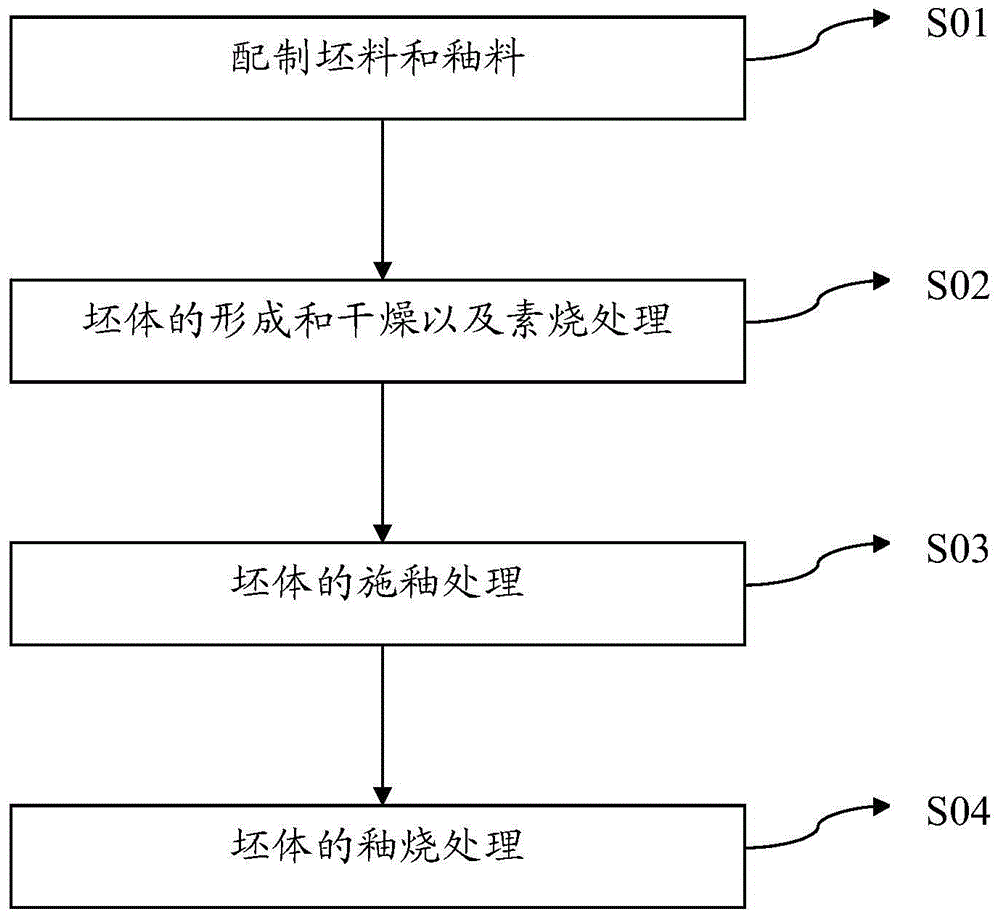

[0072] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned glazed ceramic tile. In one embodiment, the process flow chart of the preparation method of the glazed ceramic tile is as follows figure 1 As shown, it includes the following steps:

[0073] Step S01. Preparing blanks and glazes: after pretreating the raw materials according to the components contained in the blanks and glazes, preparing blanks and glazes respectively;

[0074] Step S02. Forming, drying and bisque treatment of the green body: the blank is pressed into a green body and then dried and biscuited in sequence;

[0075] Step S03. Glazing treatment of the green body: performing glazing treatment on the green body after the bisque firing treatment;

[0076] Step S04. Glazing treatment of the green body: performing a glaze firing treatment on the green body after the glazing treatment.

[0077] Specifically, the components contained in the blank ...

Embodiment 1

[0090] A glazed ceramic tile and a preparation method thereof. The glazed ceramic tile is processed from a blank and a glaze, wherein the blank contains the following components by weight percentage: 65% of anaerobic digested sludge, 15% of clay, 10% of wollastonite, and 10% of talc;

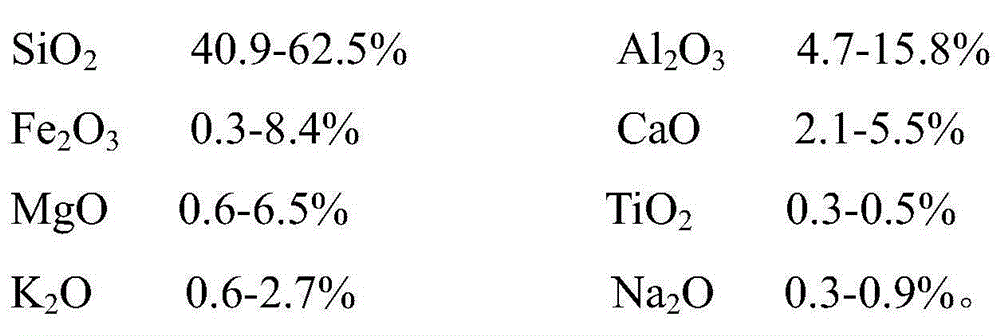

[0091] The specific blank general formula chemical composition of the present embodiment is as follows:

[0092]

[0093] The components contained in the glaze by weight percentage are: 85% of frit, 13% of bentonite and 2% of feldspar. Wherein, the formula components of the frit are by weight percentage: 25% of quartz, 25% of feldspar, 10% of dolomite, 10% of talc, 8% of borax, 6% of zinc oxide, 2% of potassium nitrate, zircon 14%.

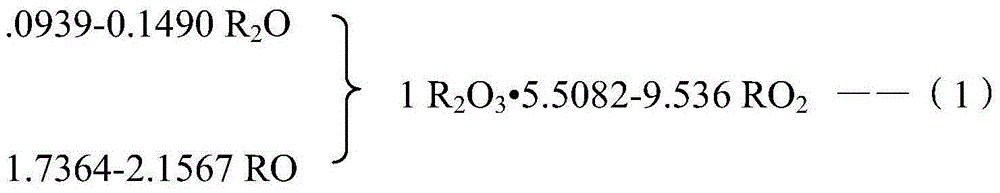

[0094] The general chemical composition of the glaze is as follows:

[0095]

[0096] The preparation method of the present embodiment 1 glazed ceramic tile is as follows:

[0097] Step S11. Preparation of blanks and glazes: The blanks and glazes of glazed...

Embodiment 2

[0105] A glazed ceramic tile and a preparation method thereof. The glazed tiles are processed from blanks and glazes. Wherein, the components contained in the blank and the glaze and the weight percentage of each component are as in Example 1.

[0106] The preparation method of the present embodiment 2 glazed tiles is as follows:

[0107] Step S21. Preparation of blanks and glazes: The blanks and glazes of glazed ceramic tiles made of anaerobic digested sludge as a main ingredient are subjected to component inspection, batching, ball milling and sieving to remove iron according to the formula. The iron removal process of the blank and the glaze adopts a wet process;

[0108] Step S22. Green body molding: put the green body prepared in step S21 into a brick press and press it, wherein the green body forming pressure is controlled at 10kgf / cm 2 ;

[0109] Step S23. Green body drying: the drying temperature is 105° C., and the drying time is 3 hours.

[0110] Step S24. Bisqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com