Low-temperature fast fired marble tile and preparation method thereof

A technology for marble and ceramic tiles, which is applied to the field of low-temperature fast-fired marble tiles and their preparation, can solve the problems of high price of flux raw materials, aggravate the global greenhouse effect, and insignificant cooling effect, and achieve low price, lower energy consumption, and lower eutectic point. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

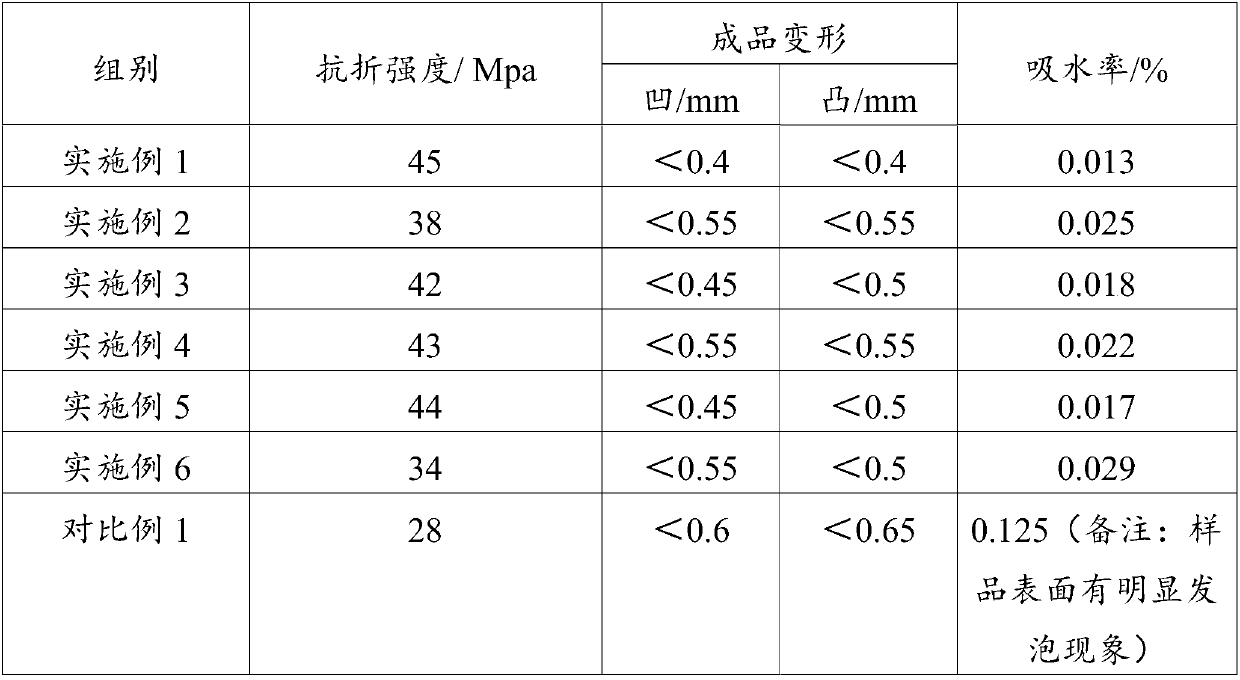

Examples

Embodiment 1

[0032] An embodiment of the low-temperature fast-fired marble tiles of the present invention, the low-temperature fast-fired marble tiles in this embodiment include the following raw materials in parts by weight: 30 parts of ultra-fine particle marble tile edging waste residue, 22 parts of potassium sodium feldspar, 25 parts of lithium porcelain stone, 18 parts of ultra-white ball clay, 1 part of boronite, 2 parts of wollastonite and 2 parts of talc; the ultrafine particle marble tile edging waste slag is the waste slag produced in the marble tile edging process section, so The particle size D of ultra-fine particle marble tile edging waste residue 50 10~18μm, D 90 It is 45-60 μm.

[0033] The preparation method of the ultra-low temperature sintered ceramic tile of the present embodiment comprises the following steps:

[0034] (1) Collection of ultra-fine marble tile edging residue:

[0035] (a), collect the waste water containing fine particles produced in the edging proce...

Embodiment 2

[0043] An embodiment of the low-temperature fast-fired marble tiles of the present invention, the low-temperature fast-fired marble tiles in this embodiment include the following raw materials in parts by weight: 35 parts of ultrafine particle marble tile edging waste residue, 12 parts of potassium sodium feldspar, 30 parts of lithium china stone, 17 parts of ultra-white ball clay, 1 part of boronite, 3 parts of wollastonite and 2 parts of talc; the ultrafine particle marble tile edging waste slag is the waste slag produced in the marble tile edging process section, so The particle size D of ultra-fine particle marble tile edging waste residue 50 10~18μm, D 90 It is 45-60 μm.

[0044] The preparation method of the ultra-low temperature sintered ceramic tile of the present embodiment comprises the following steps:

[0045] (1), the collection of superfine particle marble tile edging waste residue: with embodiment 1;

[0046] (2), mix raw materials, add in ball mill and carry...

Embodiment 3

[0051] An embodiment of the low-temperature fast-fired marble tiles of the present invention, the low-temperature fast-fired marble tiles in this embodiment include the following raw materials in parts by weight: 30 parts of ultra-fine particle marble tile edging waste residue, 15 parts of potassium sodium feldspar, 25 parts of lithium porcelain stone, 10 parts of low-temperature sand, 15 parts of Huadu Baini, 1 part of boron calcium stone, 2 parts of wollastonite and 2 parts of talc; the ultrafine grain marble tile edging waste residue is the marble tile edging process The waste slag produced in the section, the particle size D of the ultrafine particle marble tile edging waste slag 50 10~18μm, D 90 It is 45-60 μm.

[0052] The preparation method of the ultra-low temperature sintered ceramic tile of the present embodiment comprises the following steps:

[0053] (1), the collection of superfine particle marble tile edging waste residue: with embodiment 1;

[0054] (2), mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com