A kind of ultrasonic-assisted welding method of magnesium alloy with pure Pb as intermediate reaction material layer

A reactive material, ultrasonic-assisted technology, used in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of long welding time, high welding temperature, and easy softening of the base metal to be welded.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

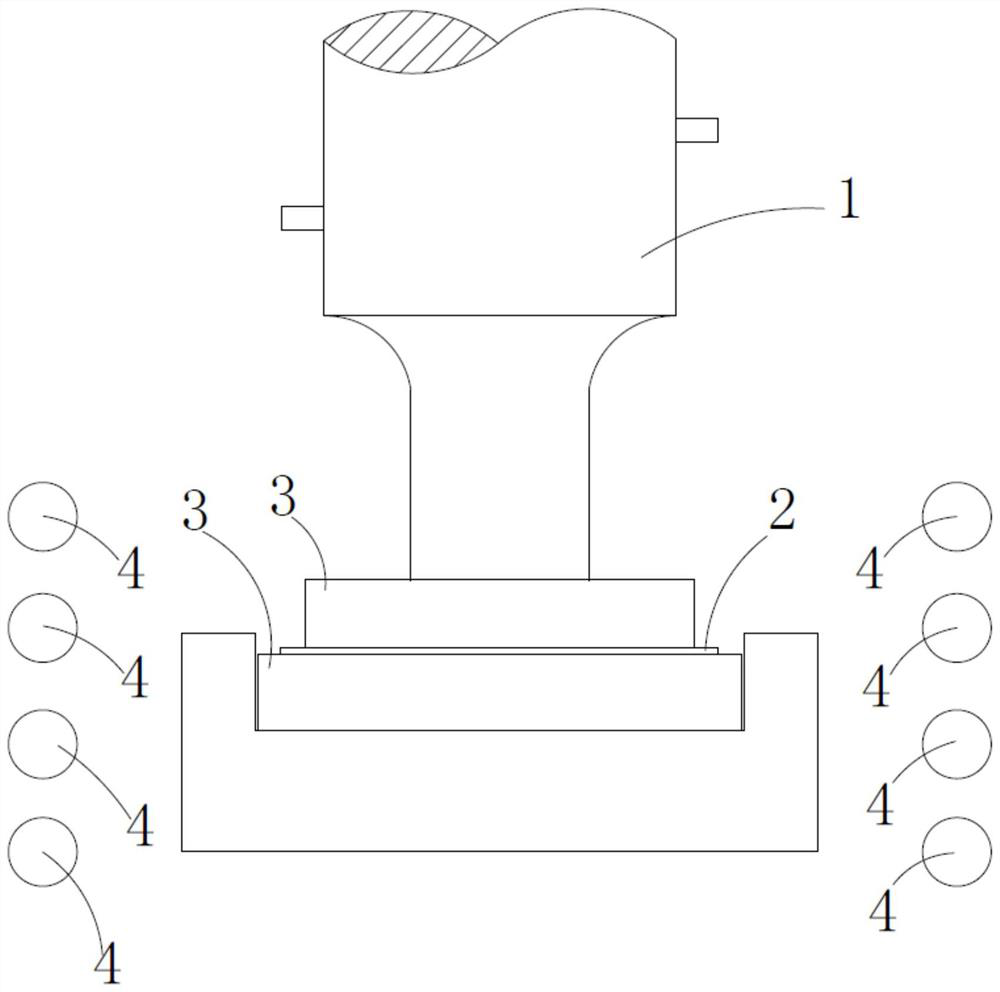

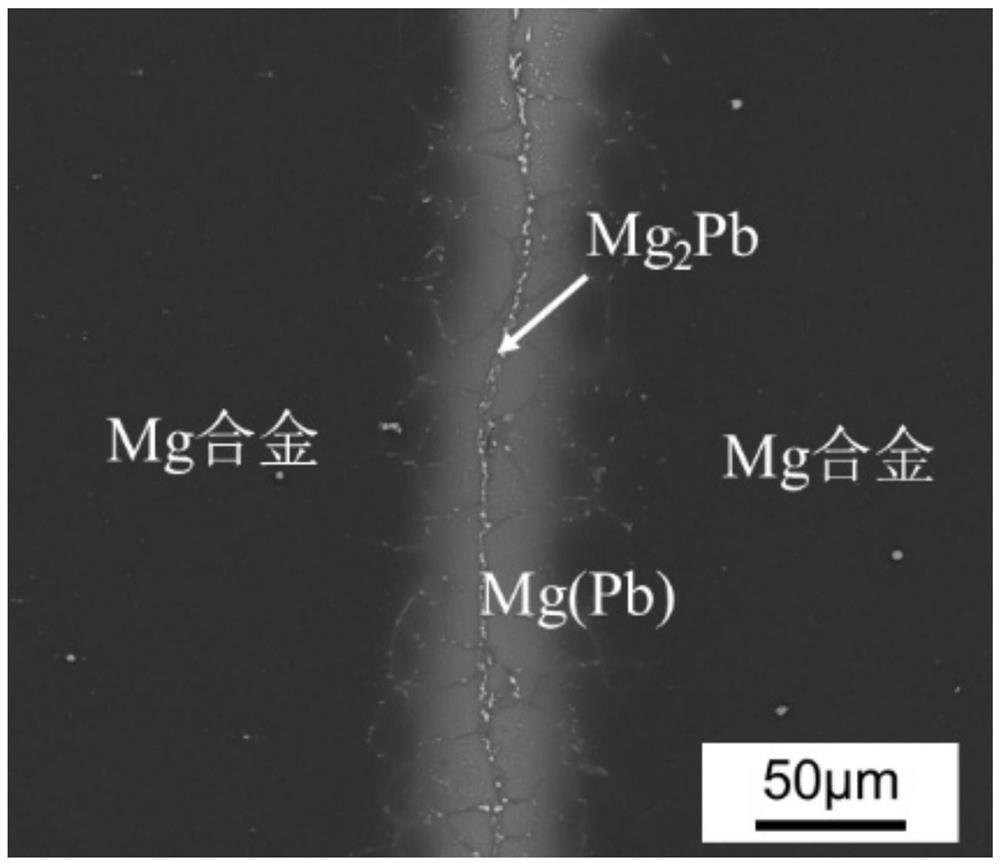

[0041] A magnesium alloy ultrasonic assisted welding method with pure Pb as the intermediate reaction material layer includes the base material to be welded 3 and the intermediate reaction material layer 2. The base material to be welded 3 is limited to magnesium alloys, and includes the following steps: figure 1 As shown, the intermediate reaction material layer 2 screening step,

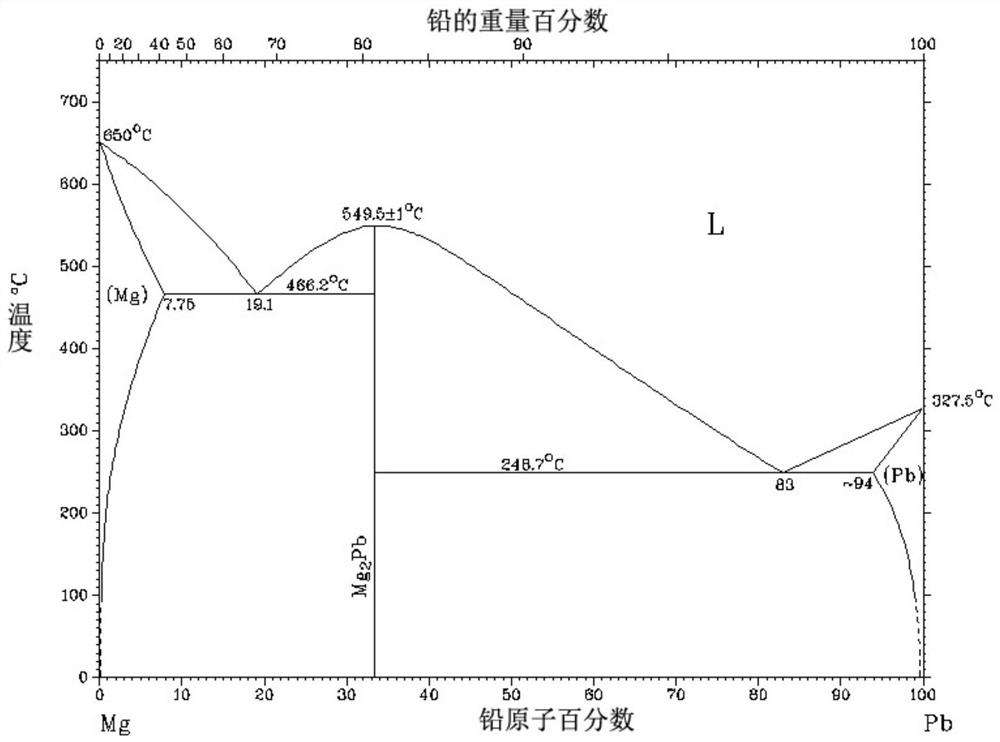

[0042] Condition 1: The melting temperature of the intermediate reaction material layer 2 is lower than the melting point of the base material 3 to be welded by 195-205°C, or the eutectic temperature between the main elements of the intermediate reaction material layer 2 and the base material to be welded 3 is lower than that of the base material to be welded. The melting point of the material is 150-300℃,

[0043] Condition 2: The maximum solid solubility between the main elements of the intermediate reaction material layer 2 and the base material 3 to be welded reaches at least 10%,

[0044] Condition 3...

Embodiment 2

[0069] The main structure, principle and effect of this embodiment are the same as those of the first embodiment, and will not be repeated here. The difference is that the base material 3 to be welded is selected from ME20M magnesium alloy.

Embodiment 3

[0071] The main structure, principle, and effect of this embodiment are the same as those of the first embodiment, and will not be repeated here. The difference is that the thickness of the pure Pb foil is 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com