Ultra-low temperature sintered ceramic tiles and preparation method thereof

A technology of ultra-low temperature and ceramic tiles, which is applied in the field of architectural ceramics. It can solve problems such as difficulty in guaranteeing product performance indicators, shortening the firing temperature range, and easy deformation and brittleness of products. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. The ultra-low temperature sintered tiles of this embodiment are composed of raw materials by weight percentage:

[0026] Lithium china stone 35%, low temperature sand 20%, potassium albite feldspar 23%, nepheline 5%, talc 5%, mixed soil 5%, washed pure mud 5%, boronite 2%.

[0027] 2. The preparation method of ultra-low temperature sintered tiles in this embodiment is as follows:

[0028] (1) Add the above-mentioned raw materials in the ball mill, mix and carry out ball milling according to raw materials: ball: water=1: 2.0: 0.8;

[0029] (2) Sieving, drying, granulating, and compression molding are carried out successively;

[0030] (3) Firing at a firing temperature range of 1050-1120°C, the total firing time is 60 minutes, and the holding time is 15 minutes to obtain the product.

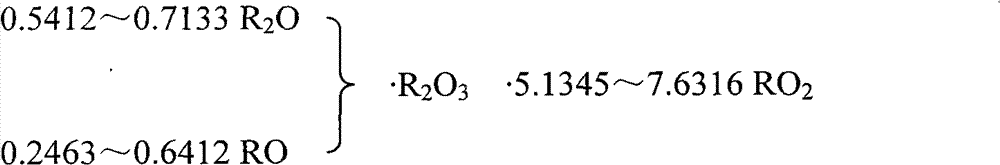

[0031] The blank form of the obtained green body is:

[0032]

[0033] 3. Product technical indicators:

[0034] Flexural strength: 56.47Mpa; deformation rate: less than 5%; ther...

Embodiment 2

[0036] 1. The ultra-low temperature sintered tiles of this embodiment are composed of raw materials by weight percentage:

[0037] 30% lithium china stone, 30% low temperature sand, 18% potassium albite feldspar, 10% nepheline, 4% talc, 6% mixed soil, and 2% boronite.

[0038] 2. The preparation method of ultra-low temperature sintered tiles in this embodiment is as follows:

[0039] (1) Add the above-mentioned raw materials in the ball mill, mix and carry out ball milling according to raw materials: ball: water=1: 1.5: 0.6;

[0040] (2) Sieving, drying, granulating, and compression molding are carried out successively;

[0041] (3) Firing at a firing temperature range of 1060-1120°C, the total firing time is 50 minutes, and the holding time is 20 minutes to obtain the product.

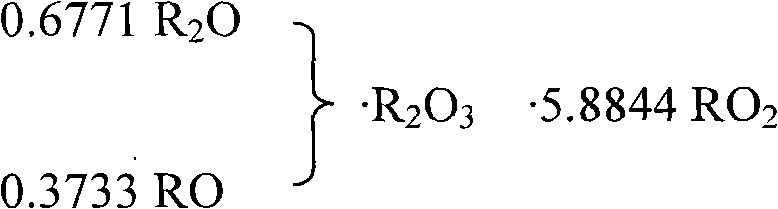

[0042] The blank form of the obtained green body is:

[0043]

[0044] 3. Product technical indicators:

[0045] Flexural strength: 52.44Mpa; deformation rate: less than 5%; thermal stability, re...

Embodiment 3

[0047] 1. The ultra-low temperature sintered tiles of this embodiment are composed of raw materials by weight percentage:

[0048] Lithium china stone 30%, low temperature sand 25%, potassium albite feldspar 15%, nepheline 12%, talc 5%, mixed soil 6%, washed pure mud 4%, boronite 3%.

[0049] 2. The preparation method of ultra-low temperature sintered tiles in this embodiment is as follows:

[0050] (1) Add the above-mentioned raw materials in the ball mill, mix and carry out ball milling according to raw materials: ball: water=1: 1.6: 0.7;

[0051] (2) Sieving, drying, granulating, and compression molding are carried out successively;

[0052] (3) Firing at a firing temperature range of 1060-1120°C, the total firing time is 70 minutes, and the holding time is 10 minutes to obtain the product.

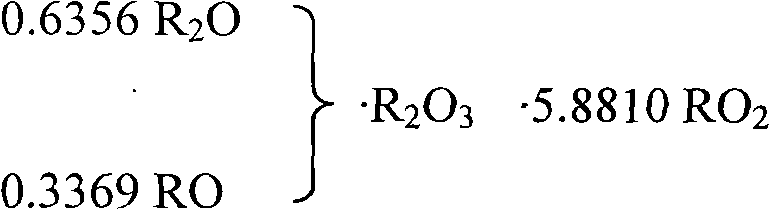

[0053] The blank form of the obtained green body is:

[0054]

[0055] 3. Product technical indicators:

[0056] Flexural strength: 68.42Mpa; deformation rate: less than 5%; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com