Inking process of automobile glass

A technology of automotive glass and glass ink, applied in the directions of ink, application, coating, etc., can solve the problem of rainwater acid corrosion of ink layer, and achieve the effect of reducing acid corrosion, good gloss, and wide sintering temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

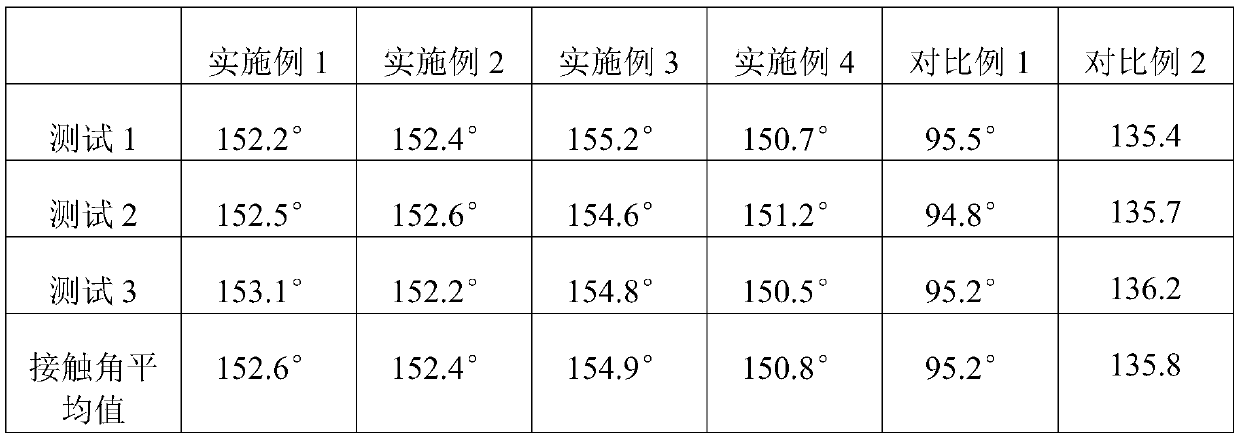

Examples

Embodiment 1

[0029] Embodiment 1 automobile glass ink technology, comprises the following steps:

[0030]1) Preparation of varnish: Add polyvinyl butyral to n-amyl alcohol solvent at a weight ratio of 1:30, heat up to 85°C in a water bath, stir until dissolved, and obtain varnish;

[0031] 2) Preparation of low-melting glass powder: take Bi by weight 2 o 3 30 parts, SiO 2 50 copies, B 2 o 3 15 parts, ZnO10 parts, Na 2 O10 parts, ZrO 2 3 parts, TiO 2 5 copies, Al 2 o 3 4 copies, K 2 CO 3 5 copies;

[0032] Put the weighed above-mentioned ingredients in a ceramic mortar, grind and mix them evenly, put them in a muffle furnace and melt them at 1160°C, anneal the molten glass at 550°C for 1 hour, and cool down to obtain a low-melting glass. The glass is pulverized and ground to a particle size of 10 μm to obtain low-melting glass powder;

[0033] 3) Preparation of glass ink: 60 parts by weight of low-melting glass powder, 30 parts of copper chrome black pigment, 35 parts of varni...

Embodiment 2

[0041] Embodiment 2 automotive glass ink technology, comprises the following steps:

[0042] 1) Preparation of varnish: Add polyvinyl butyral to n-amyl alcohol solvent at a weight ratio of 1:20, heat up to 85°C in a water bath, stir until dissolved, and obtain varnish;

[0043] 2) Preparation of low-melting glass powder: take Bi by weight 2 o 3 25 parts, SiO 2 30 copies, B 2 o 3 15 parts, ZnO5 parts, Na 2 O5 parts, ZrO 2 1 part, TiO 2 1 part, Al 2 o 3 2 copies, K 2 CO 3 1 copy;

[0044] Put the weighed above-mentioned ingredients in a ceramic mortar, grind and mix them evenly, put them in a muffle furnace and melt them at 1180°C, anneal the molten glass at 500°C for 3 hours, and cool down to obtain a low-melting point glass. The glass is pulverized and ground to a particle size of 5 μm to obtain low-melting glass powder;

[0045] 3) Preparation of glass ink: 60 parts by weight of low melting point glass powder, 20 parts of copper chrome black pigment, 35 parts of...

Embodiment 3

[0053] Embodiment 3 automotive glass ink technology, comprises the following steps:

[0054] 1) Preparation of varnish: Add polyvinyl butyral to n-amyl alcohol solvent at a weight ratio of 1:25, heat up to 90°C in a water bath, stir until dissolved, and obtain varnish;

[0055] 2) Preparation of low-melting glass powder: take Bi by weight 2 o 3 40 parts, SiO 2 40 copies, B 2 o 3 20 parts, ZnO8 parts, Na 2 O8 parts, ZrO 2 3 parts, TiO 2 3 copies, Al 2 o 3 5 copies, K 2 CO 3 3 copies;

[0056] Put the weighed above-mentioned components in a ceramic mortar, grind and mix them evenly, put them in a muffle furnace and melt them at 1200°C, anneal the molten glass at 520°C for 2 hours, and cool down to obtain a low-melting-point glass. The glass is pulverized and ground to a particle size of 10 μm to obtain low-melting glass powder;

[0057] 3) Preparation of glass ink: 70 parts by weight of low melting point glass powder, 25 parts of copper chrome black pigment, 40 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com