Two-step mode two-temperature transient liquid-phase bonding method for dissimilar metals

An instantaneous liquid phase connection, dissimilar metal technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of difficult to achieve TLP connection, differences in chemical and metallurgical properties, melting of low-melting base metals, etc., to promote joints. The effect of homogenizing ingredients, improving joining performance, preventing melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

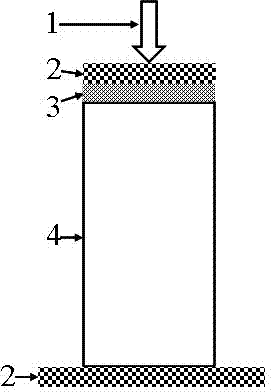

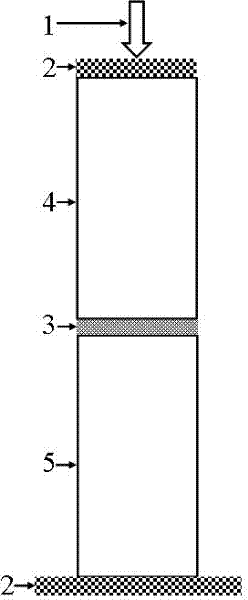

[0033] Example 1: 5083 aluminum alloy and TC4 titanium alloy with a diameter of 16mm were welded using a two-step dual-temperature transient liquid phase (TLP) connection method, with a copper foil with a thickness of 150 μm as the intermediate layer. The process parameters are: the first TLP connection: the temperature is 885-900°C, the external load is 0.2MPa, and the time is 3 minutes; the second TLP connection: the temperature is 555°C, the external load is 0.2MPa, and the time is 5 minutes. The results of microscopic analysis showed that effective connection was achieved.

example 2

[0034] Example 2: AZ31B magnesium alloy and 5083 aluminum alloy with a diameter of 16mm were welded using a two-step dual-temperature transient liquid phase (TLP) connection method with a copper foil with a thickness of 150 μm as the intermediate layer. The process parameters are: the first TLP connection: the temperature is 555-570°C, the external load is 0.2MPa, and the time is 2 minutes; the second TLP connection: the temperature is 495°C, the external load is 0.2MPa, and the time is 10 minutes. The results of microscopic analysis showed that effective connection was achieved.

example 3

[0035]Example 3: AZ31B magnesium alloy and TC4 titanium alloy with a diameter of 16mm were welded using a two-step dual-temperature transient liquid phase (TLP) joining method with a copper foil with a thickness of 150 μm as the intermediate layer. The process parameters are: the first TLP connection: the temperature is 885-900°C, the external load is 0.2MPa, and the time is 3 minutes; the second TLP connection: the temperature is 495°C, the external load is 0.2MPa, and the time is 10 minutes. The results of microscopic analysis showed that effective connection was achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com