Automobile warm-air

A warm air and automobile technology, applied in the direction of heat exchanger fixation, heat exchange equipment, fixed conduit components, etc., can solve problems such as leakage and scrapping, poor sealing, aging and damage of flat tubes, etc., to increase the overall rigidity and ensure Welding quality, effect of increasing cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

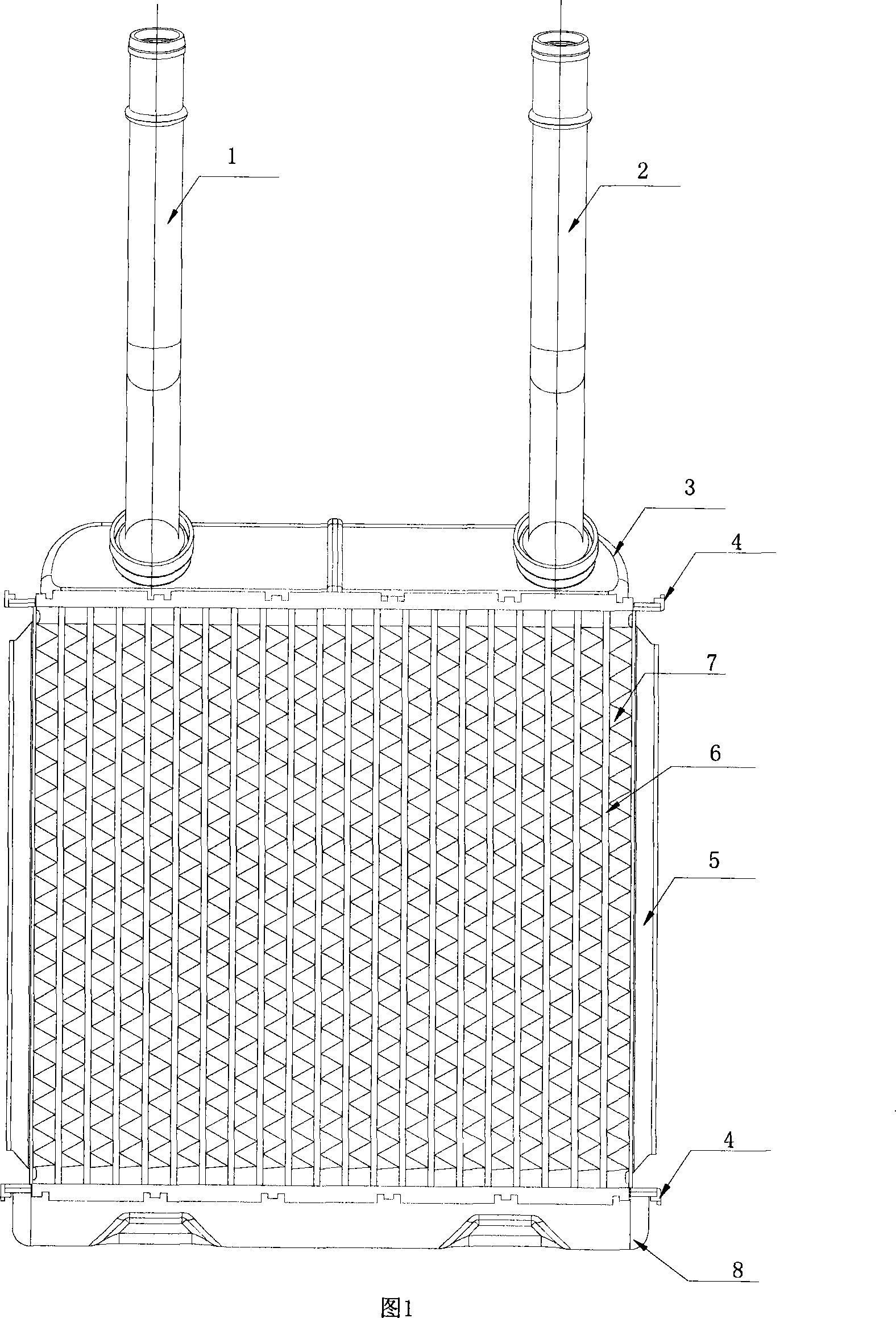

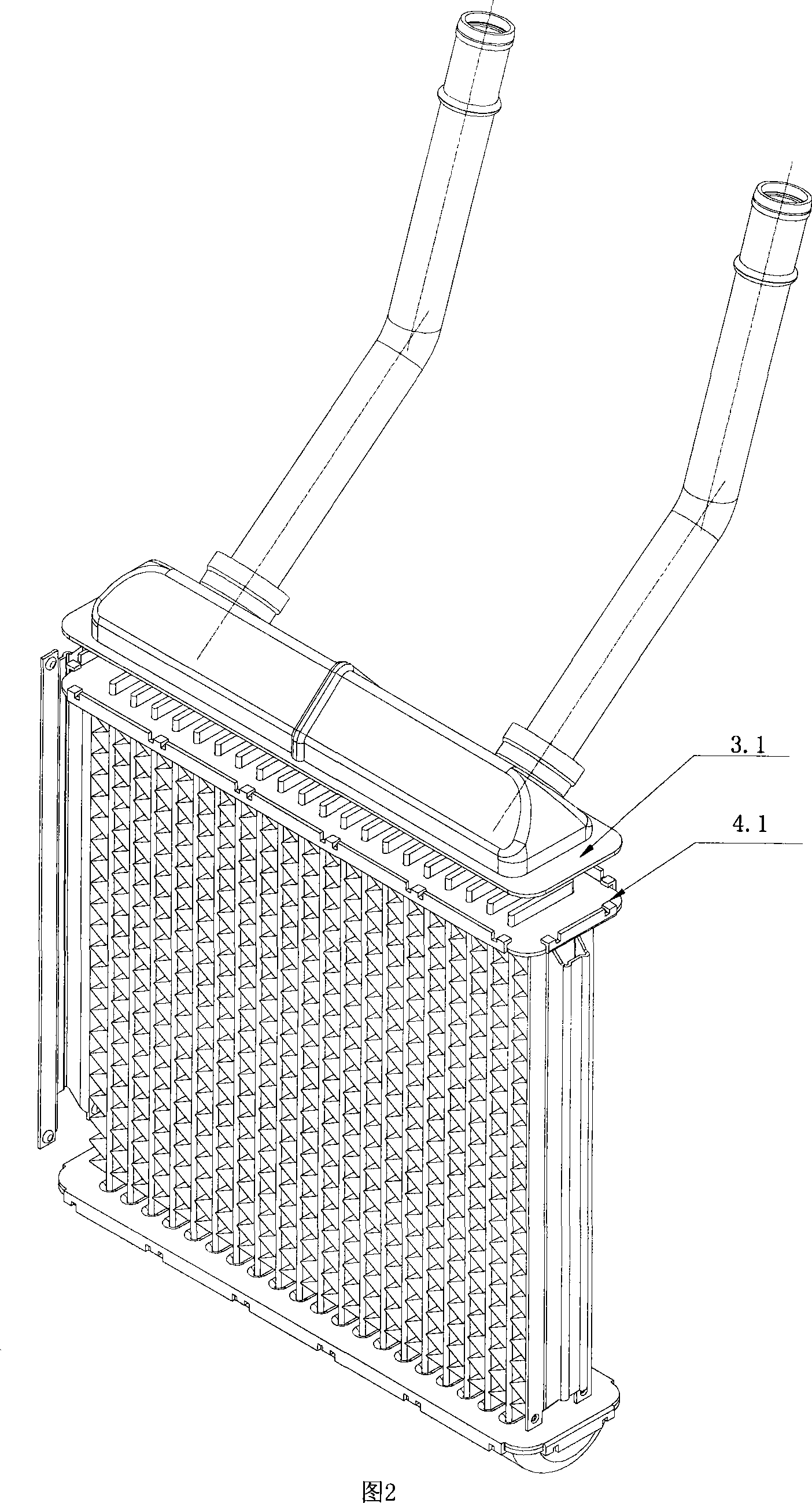

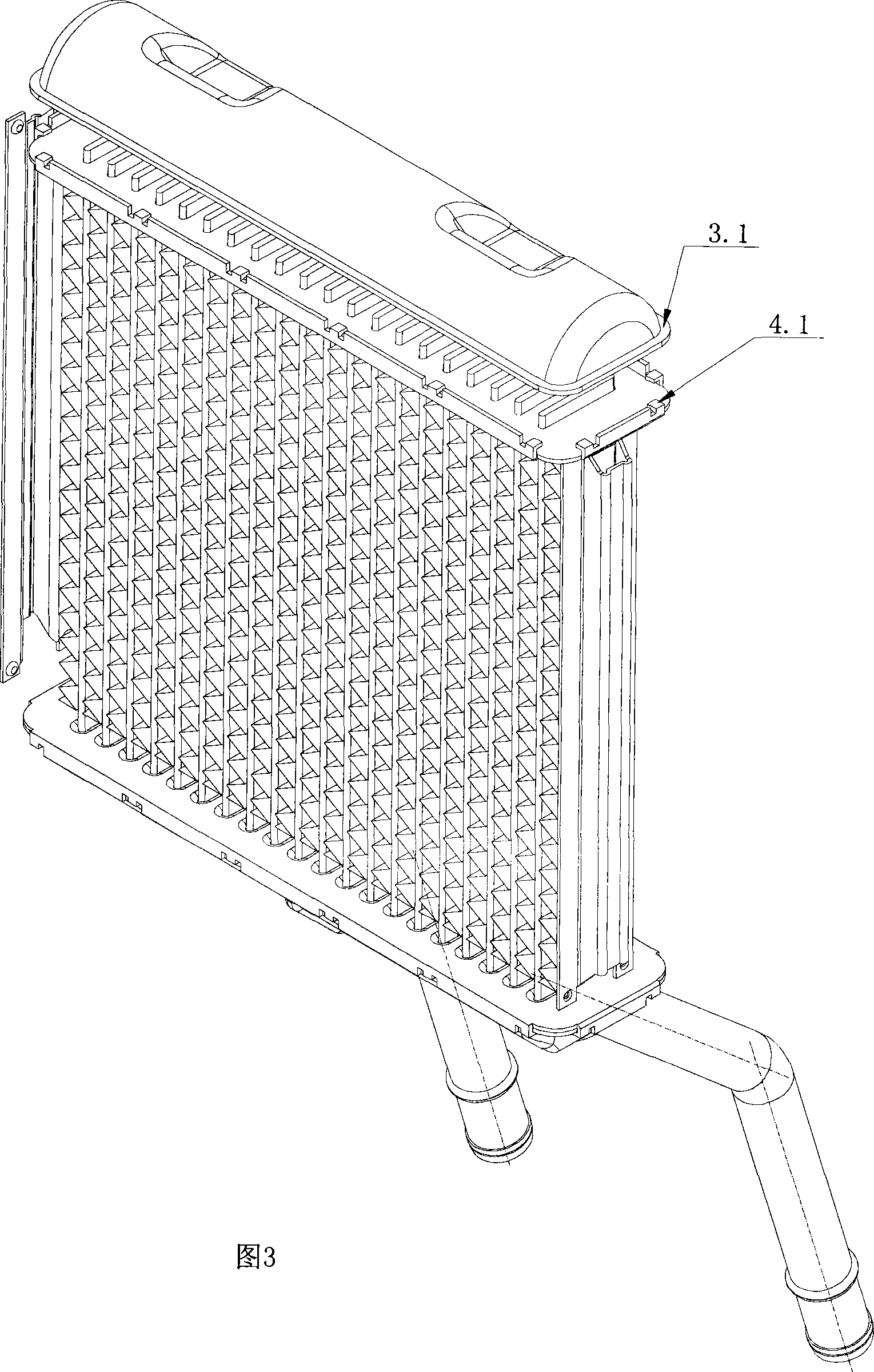

[0036] Referring to Figure 1, the car heater is structurally divided into eight parts: water inlet pipe 1, water outlet pipe 2, upper water chamber 3, lower water chamber 8, main piece 4, flat pipe 6, heat dissipation belt 7 and side plate 5. The main piece 4 is provided with several tooth pieces 4.1 around its connection with the upper water chamber 3 and the lower water chamber 8, as shown in Figures 2, 3, 4 and 5. When assembling, the teeth pieces 4.1 are engaged with the edge 3.1 of the joint (bottom) of the upper water chamber 3 and the lower water chamber 8 with the main piece 4, and then brazed, as shown in Figures 6 and 7. This structure can be applied to the connection between the main piece and the water chamber of all types of automobile heaters and engineering water tanks.

[0037] Described side plate 5 is respectively provided with two bulges 5.1 or two elbows 5.2 on the side wall of its position corresponding to the two ends of the heat dissipation strip 7, as s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com