Organic electrolyte and lithium secondary battery

An organic electrolyte, secondary battery technology, applied in secondary batteries, organic electrolytes, non-aqueous electrolytes, etc., can solve the problems of SEI film instability, safety hazards, consumption, etc., to improve electrochemical performance, chemical reaction inhibition Effect

Inactive Publication Date: 2016-02-03

TSINGHUA UNIV

View PDF3 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the lithium negative electrode of the lithium metal secondary battery will chemically react with the organic electrolyte or the inorganic electrolyte during the charging and discharging process to form an SEI film, and will generate lithium dendrites due to the uneven conduction of the current during the charging and discharging process, Makes lithium metal secondary batteries useless and a safety hazard

[0003] In the prior art, two methods are usually used to suppress the chemical reaction between the lithium negative electrode and the organic electrolyte: one method is to add additives such as inorganic salts or organic small molecules to the organic electrolyte, and the inorganic salts or organic small molecules are in the lithium metal. During the use of the secondary battery, a solid electrolyte film (SEI film) can be formed on the lithium negative electrode, thereby inhibiting the chemical reaction between the lithium negative electrode and the organic electrolyte. However, the SEI film produced by this method is still incompatible with the organic electrolyte. The SEI film is in direct contact with the liquid, so the SEI film is very unstable and will be gradually consumed during the electrochemical reaction, making it difficult for the lithium metal secondary battery to obtain stable electrochemical performance; another method is to coat the surface of the lithium negative electrode with Coated with a solid polymer layer, the solid polymer layer is conducive to reducing the direct contact between the lithium negative electrode and the organic electrolyte, reducing the occurrence of irreversible chemical reactions between the lithium negative electrode and the electrolyte, but the solid polymer layer will largely The migration of electron ions is retarded, thereby reducing the electrochemical performance of lithium metal secondary batteries

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

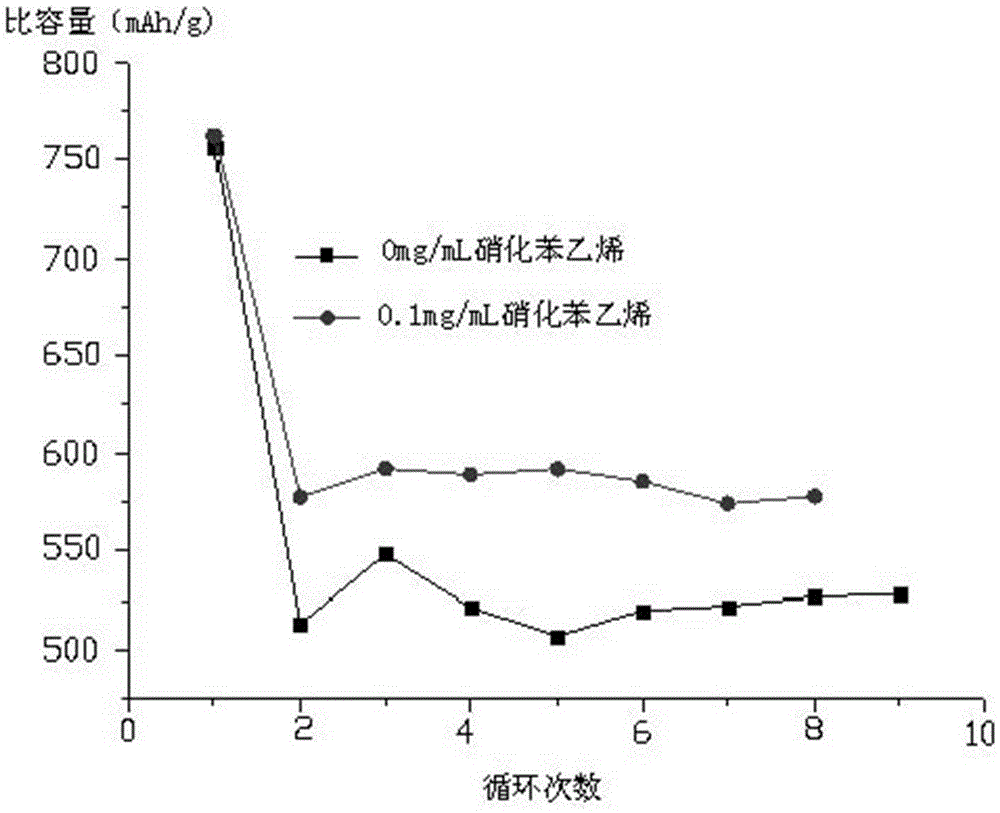

[0027] The organic electrolyte is to dissolve nitrated polystyrene and 1M LiTFSI in a solvent composed of DOL / DME=1 / 1 (v / v). The polymerization degree n of the nitrated polystyrene is 200, m:n=1:5, and the concentration of the nitrated polystyrene in the organic electrolyte is 0.1 mg / ml.

[0028] The snap-button battery assembly method combines lithium sheets with vulcanized polyacrylonitrile to form batteries.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses organic electrolyte which comprises an organic solvent, electrolyte salt and an additive, wherein the electrolyte salt and the additive are dissolved in the organic solvent; the additive is a nitro-containing high-molecular compound which comprises n constitutional repeating units; m nitros are distributed on the n constitutional repeating units; n is larger than or equal to 100; the ratio of m to n is larger than or equal to 0.01 and is smaller than or equal to 1. The invention further provides a lithium secondary battery containing the organic electrolyte.

Description

technical field [0001] The invention relates to an organic electrolytic solution containing polymer electrolyte additives and a lithium metal secondary battery containing the electrolytic solution. Background technique [0002] The use of lithium metal as an anode material has the advantages of low density, high theoretical capacity, and low site location, which can significantly reduce the volume and quality of the battery. However, the lithium negative electrode of the lithium metal secondary battery will chemically react with the organic electrolyte or the inorganic electrolyte during the charge and discharge process to form an SEI film, and will generate lithium dendrites due to the uneven conduction of the current during the charge and discharge process. Make the lithium metal secondary battery invalid and pose a safety hazard. [0003] In the prior art, two methods are usually used to suppress the chemical reaction between the lithium negative electrode and the organi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M10/0525H01M10/0567

CPCH01M10/0525H01M10/0567H01M2300/0025Y02E60/10

Inventor 赵鹏王莉何向明尚玉明李建军

Owner TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com