Magnetism measuring device, manufacturing method of magnetism measuring device, gas cell, and manufacturing method of gas cell

A manufacturing method and magnetic measurement technology, applied in measuring devices, magnetic resonance measurement, magnetic field measurement using magneto-optical equipment, etc., can solve the problem of reduction, reduction in manufacturing yield of gas chambers and magnetic measurement devices, and inability to maintain magnetic measurement for a long time Device sensitivity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0050]

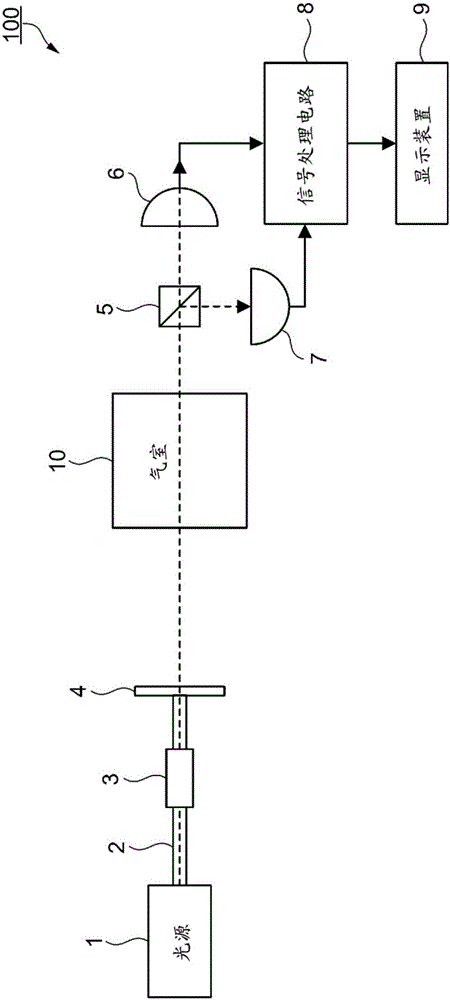

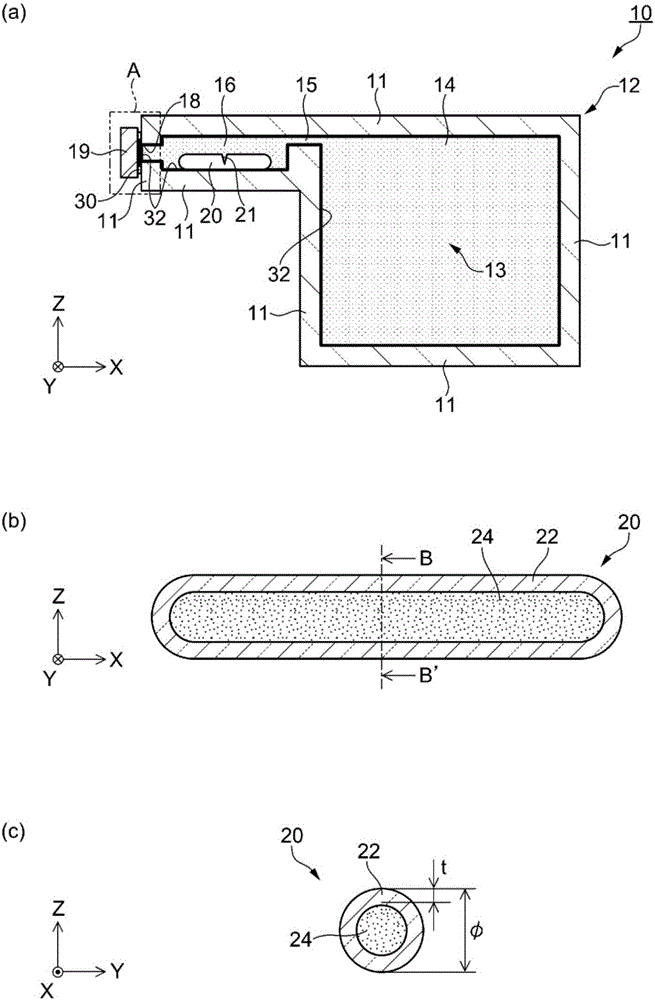

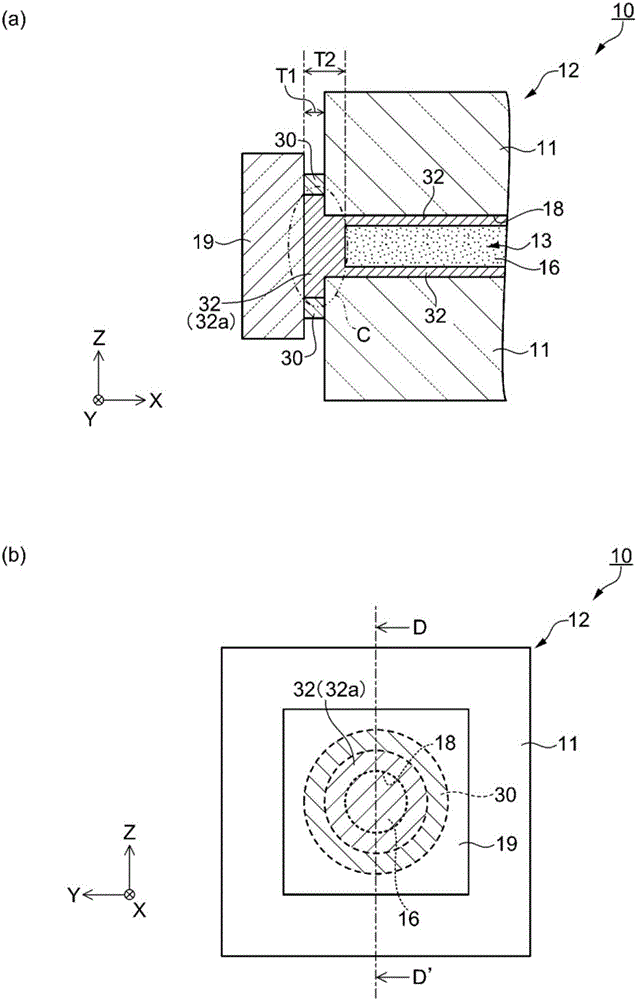

[0051] refer to figure 1 The configuration of the magnetic measurement device according to the first embodiment will be described. figure 1 It is a block diagram showing the structure of the magnetic measuring device of the first embodiment. The magnetic measurement device 100 according to the first embodiment is a magnetic measurement device using Nonlinear Magneto-Optical Rotation (NMOR). The magnetic measuring device 100 is used, for example, as a biological state measuring device (magnetocardiometer, magnetoencephalometer, etc.) . The magnetic measuring device 100 can also be used for a metal detector or the like.

[0052] Such as figure 1 As shown, the magnetic measurement device 100 includes a light source 1, an optical fiber 2, a connector 3, a polarizing plate 4, a gas chamber 10, a polarized light separator 5, a photo detector (Photo Detector: PD) 6, a photo detector 7, a signal processing Circuit 8 and display device 9 . An alkali metal gas (alkali m...

no. 2 Embodiment approach

[0113] In the second embodiment, the structure of the gas cell is the same as that of the first embodiment, but a part of the method of manufacturing the gas cell is different. More specifically, there is a difference in that a partition plate is used in the cooling step of manufacturing the gas chamber. Here, differences from the first embodiment in the cooling step will be described.

[0114]

[0115] Figure 8 It is a figure explaining the heating process and cooling process of the manufacturing method of the gas cell of 2nd Embodiment. In the heating step and cooling step of the second embodiment, as Figure 8 As shown, the configuration divides the chamber 202 of the oven 200 into the inside ( Figure 8 The partition plate 206 of the first part 202a on the +X direction side) and the second part 202b on the door 204 side is different from the first embodiment.

[0116]The partition plate 206 is formed of a plate-shaped member. The purpose of the partition plate 206 ...

no. 3 Embodiment approach

[0122] In the third embodiment, a part of the structure of the gas cell is different from the above-mentioned embodiment, and accordingly, the forming process in the manufacturing method of the gas cell is different. Here, differences from the above-described embodiment in the structure and formation steps of the gas cell will be described. Figure 10 It is a figure explaining the formation process of 3rd Embodiment.

[0123]

[0124] Figure 10 (c) shows the gas chamber 10A at the end of the forming process of the third embodiment. Such as Figure 10 As shown in (c), the gas chamber 10A of the third embodiment consists of a chamber portion 12A as a closed container and a cover portion 19 similar to the above embodiment (refer to figure 2 (a)) constitutes. The chamber portion 12A includes a concave container body 12a and an upper cover 12b disposed on the upper side of the container body 12a. The container main body 12 a has a recessed portion serving as the main chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com