Solid oxide fuel cell stack and preparation method thereof

A fuel cell stack and solid oxide technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as large interface stress, long manufacturing cycle, complex interface reaction, etc., achieve small thermal stress and improve long-term stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The inventors optimized the preparation process of the battery stack to form a battery stack structure with a special structure without using metal connecting plates.

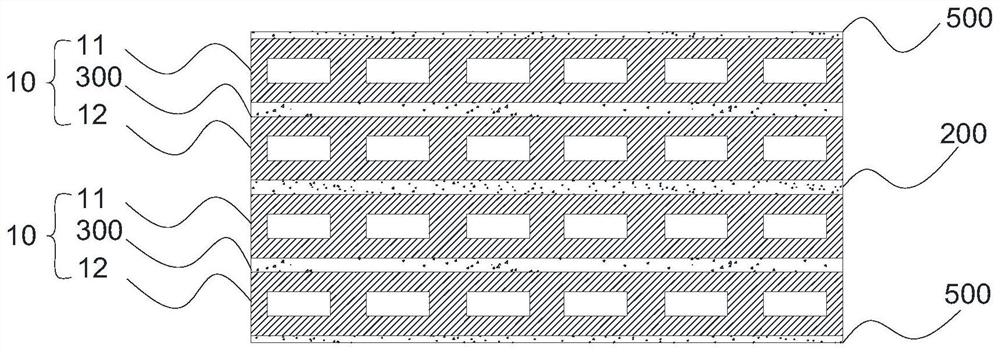

[0019] An embodiment of the present invention provides a method for preparing a solid oxide fuel cell stack. The inventor creatively uses a plurality of porous ceramic skeletons with loading holes, and stacks them layer by layer by forming electrolyte membrane layers and ceramic connector membrane layers; The anode material is loaded in a porous ceramic skeleton, and the cathode material is loaded in another adjacent porous ceramic skeleton to form a battery stack in which the anode layer and the cathode layer are stacked alternately.

[0020] Below in conjunction with accompanying drawing, the specific operation steps of preparation method are introduced:

[0021] S1. Preparation of porous ceramic framework

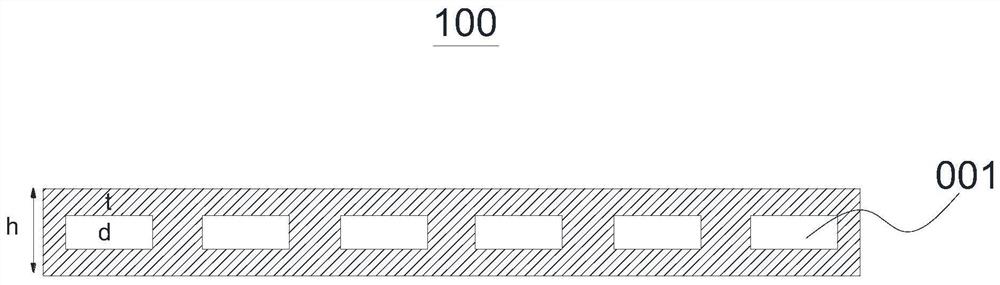

[0022] Please refer to figure 1 , the electrolyte material and the pore forming agent are use...

Embodiment 1

[0057] This embodiment provides a method for preparing a solid oxide fuel cell stack, please combine Figure 1-3 , including the following steps:

[0058] (1) 8mol% Y 2 o 3 Stable ZrO 2 (8YSZ) is used as the electrolyte material and pore-forming agent graphite (90:10), the thickness of the skeleton is formed by extrusion molding method, the thickness of the skeleton is 100 μm, the ratio of the air channel height to the thickness of the skeleton is 1:3, and it is pre-fired at 1000 ° C for 3 hours Finally, the porous ceramic skeleton 100 is formed.

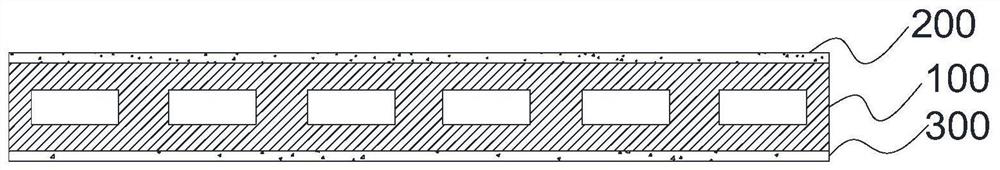

[0059] (2) Using 8YSZ as the electrolyte material, La 0.6 Sr 0.4 Cr 0.5 mn 0.5 o 3 (LSCrM) is used as the connector material, and the electrolyte membrane layer 300 and the ceramic connector membrane layer 200 are coated by the screen printing method, and the coating thickness of the electrolyte membrane layer 300 is controlled so that it is 10 μm after sintering, and the ceramic connector membrane layer 200 is controlled. ...

Embodiment 2

[0064] This embodiment provides a method for preparing a solid oxide fuel cell stack, which is roughly the same as that of Embodiment 1, and only the differences are described:

[0065] The electrolyte material uses 20mol% Gd 2 o 3 Stable CeO 2 (GDC), the connector material is GDC+La 0.6 Sr 0.4 Cr 0.5 mn 0.5 o 3 (LSCrM) as the connector material, the cathode material is La 0.8 Sr 0.2 co 0.2 Fe 0.8 o 3 (LSCF), the anode material is Ni. The sintering temperature in step (2) is 1450°C.

[0066] After testing: the battery stack adopts H 2 As fuel, air as oxidant, the peak power density at 650°C reaches 0.35W / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com