High frequency E-type and I-type film transformer and its preparing method

A transformer and thin-film technology, applied in the field of electronics, can solve the problems of complex process, low coupling efficiency, small primary and secondary inductance, etc., and achieve the effects of solving anti-interference, easy volume reduction, and improved magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

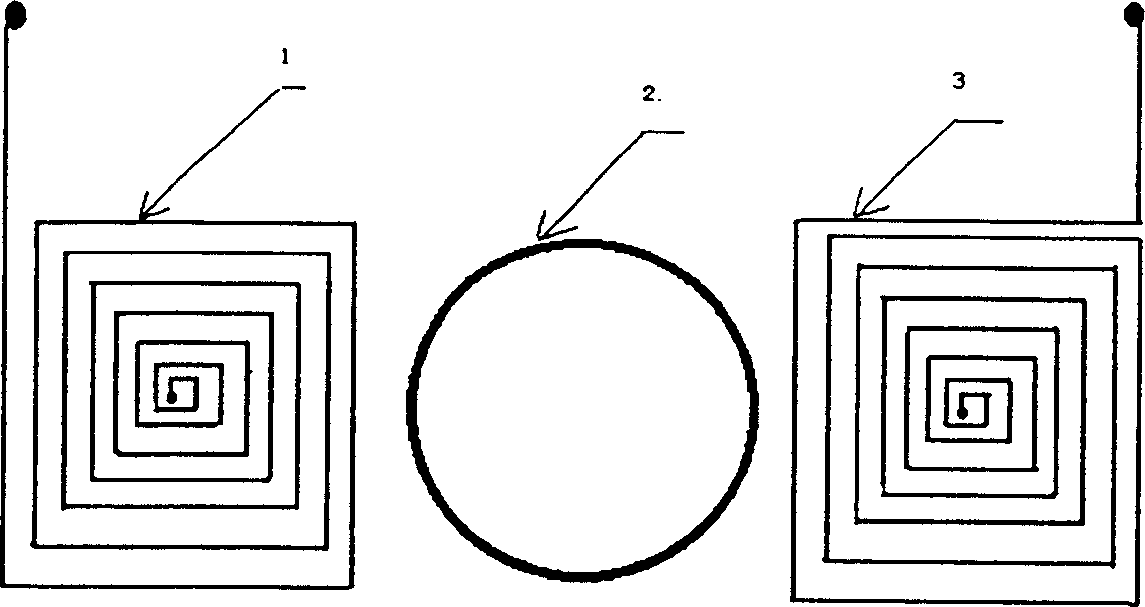

[0033] Take the E-type film transformer as an example:

[0034] Substrate size: 20×20×0.4mm;

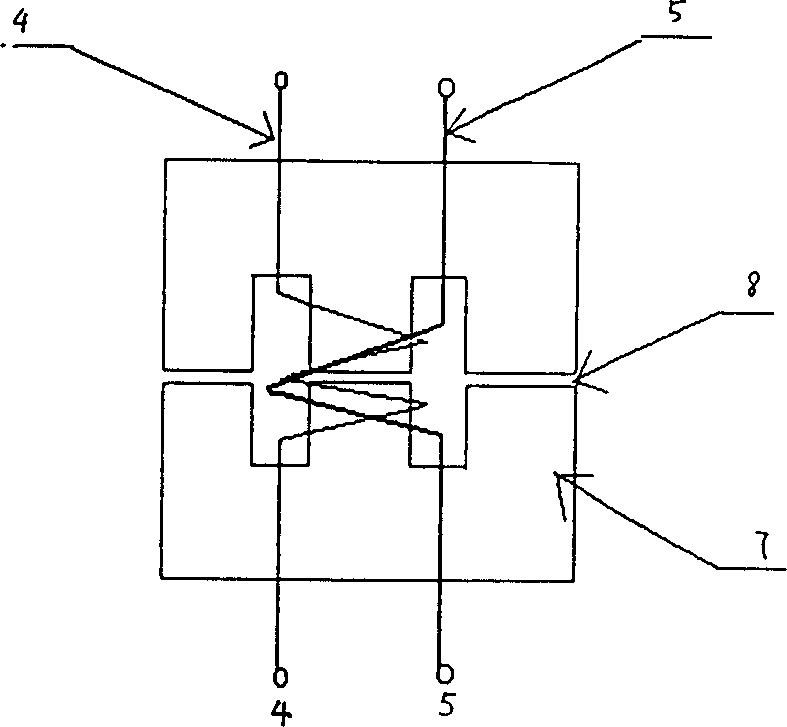

[0035] Magnetic core size: 12×9mm; winding turns ratio: 3:2;

[0036] Window size: 6×3mm;

[0037] Adopt the specific preparation technique described above of the present invention, namely:

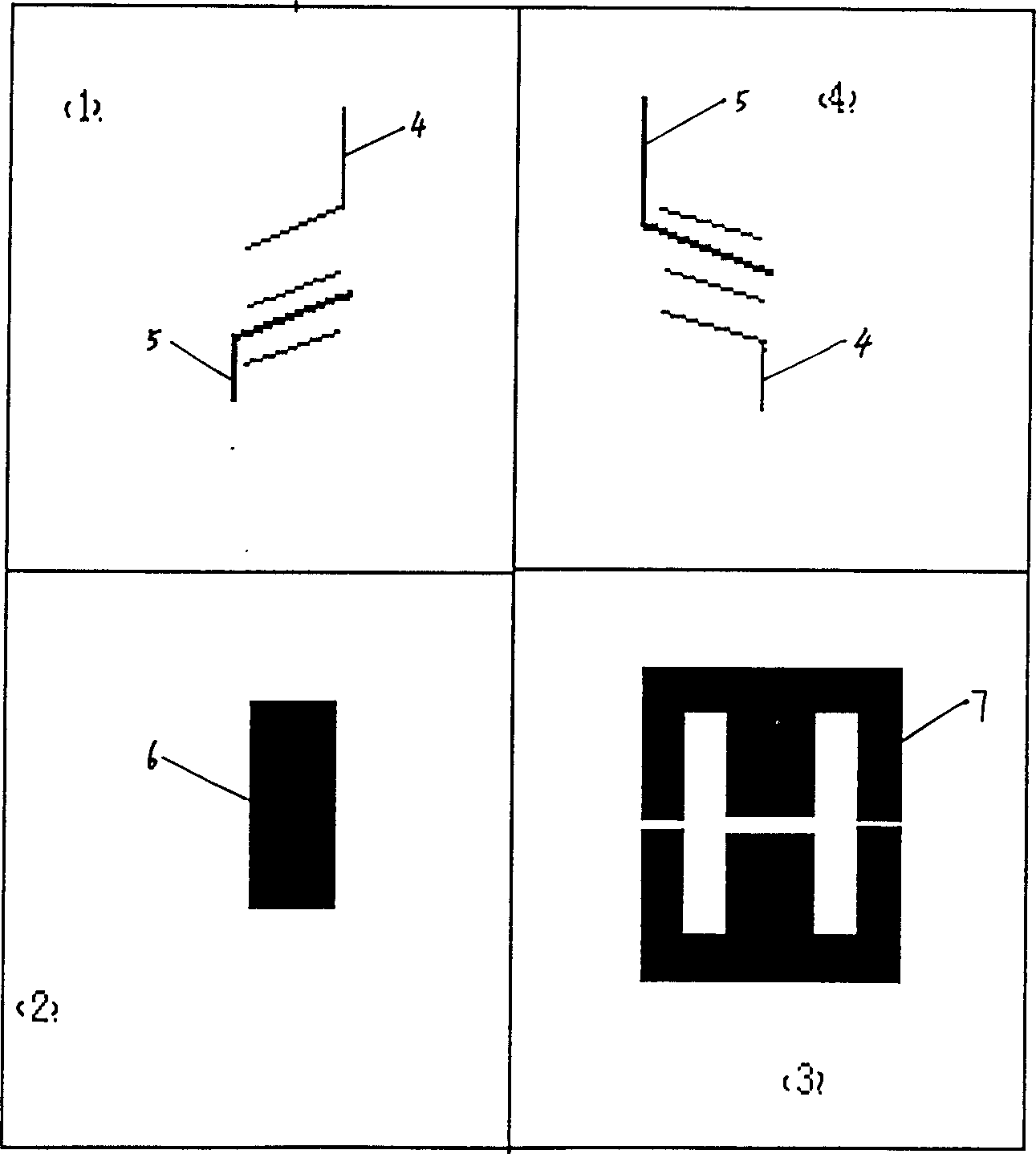

[0038] The present invention can use mask or photolithography to make thin-film transformer directly on the ceramic base and printed circuit board, adopt the method of inclining 15 degrees and 20 degrees from the vertical direction, and plate it on the thin-film magnetic core in the way of intersecting and winding. , that is, the primary and secondary film windings are wound on the E-shaped magnetic film to form an E-shaped film transformer, which greatly increases the coupling coefficient. The structure of E-type silicon-based or ceramic-based thin-film transformers is: silver lower electrode / insulating film layer / magnetic core film / insulating film layer / upper electrode silver film, and each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com