Transmitting assembly and charging assembly structure for wireless charging of electric automobile

A technology of transmitting components and wireless charging, which is applied in electric vehicle charging technology, electric vehicles, parts of transformers/inductors, etc., which can solve problems such as uneven distribution of magnetic field, inability to increase magnetic flux, and inability to guarantee charging time and charging efficiency , to achieve reasonable and compact structural design, improve wireless charging efficiency, and enhance the effect of magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

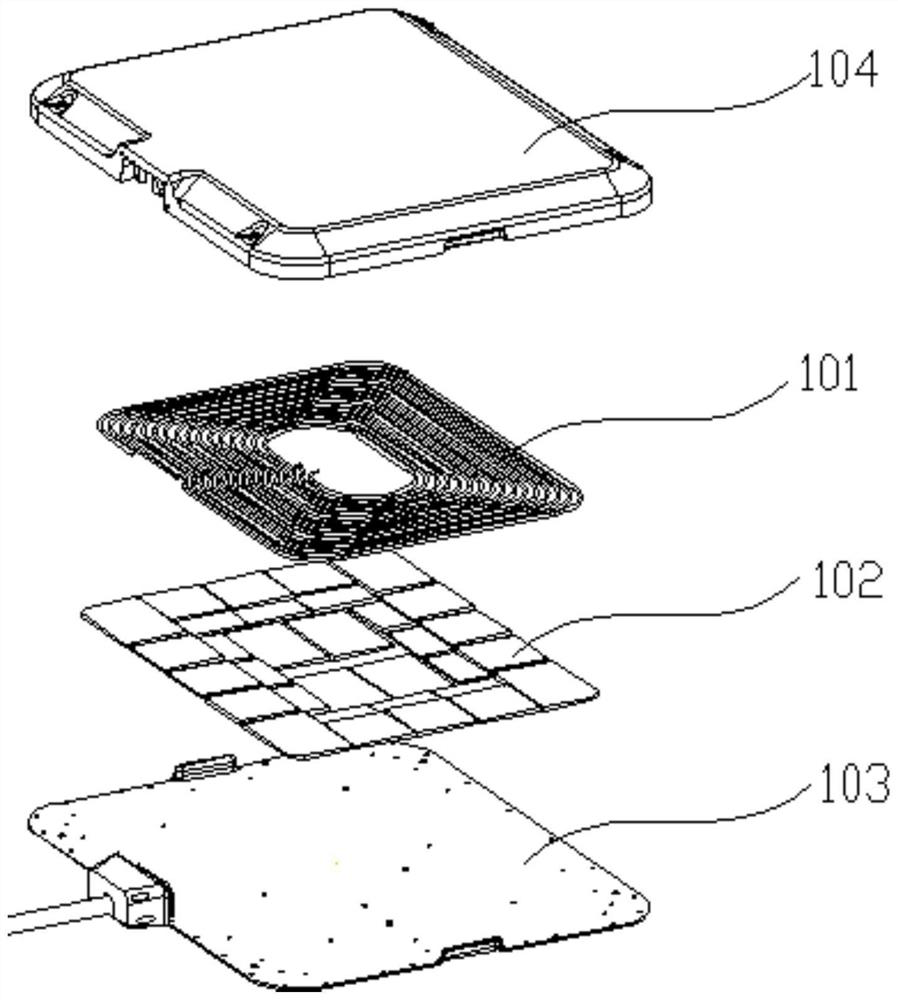

[0042] Such as figure 1 Shown is an exploded view of the transmitting assembly of the electric vehicle wireless charging assembly according to the embodiment of the present invention. The transmitting assembly includes a non-metallic shell 104 , a transmitting coil 101 , a transmitting magnetic core 102 and a metal shell 103 assembled sequentially from top to bottom. The metal shell is attached to the non-metal shell for installation, which not only serves to increase the structure, but also effectively protects EMI and enhances the cooling capacity of the coil.

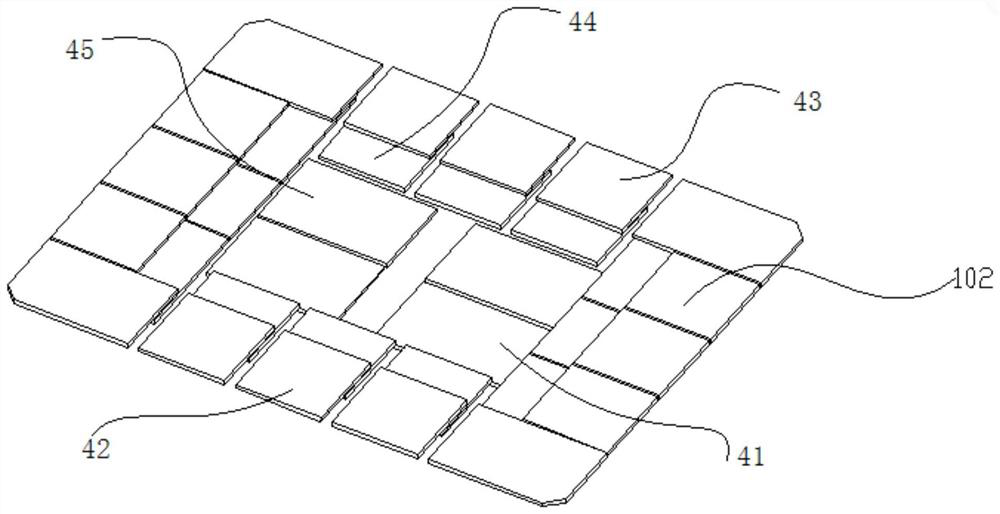

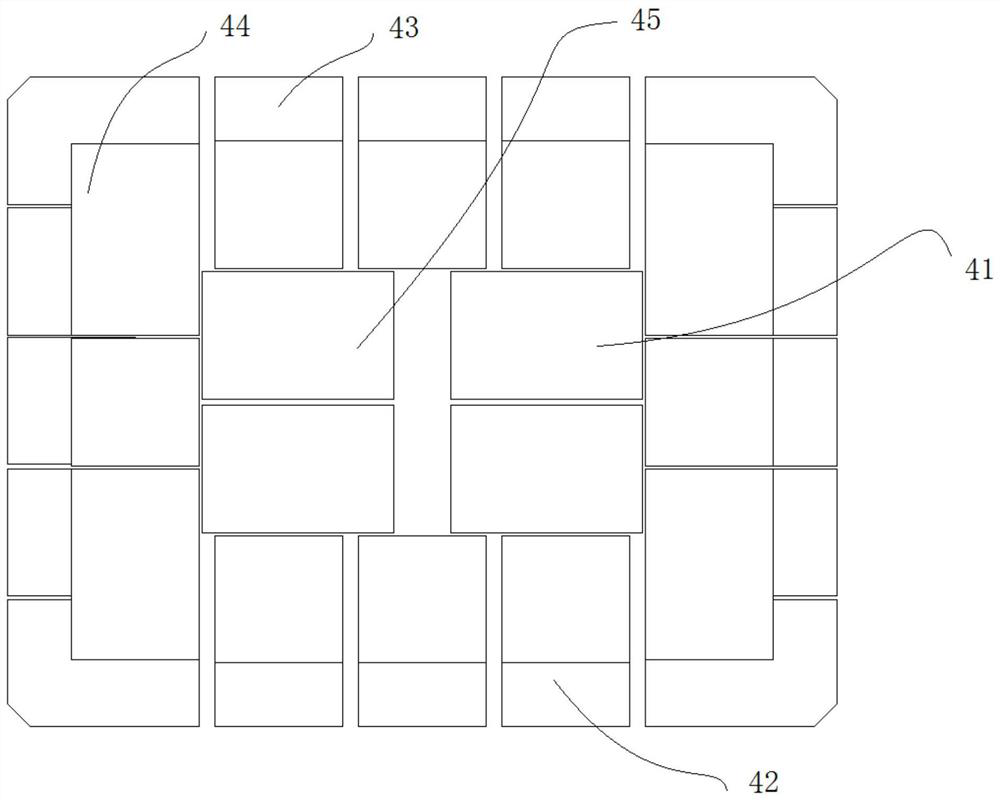

[0043] As a preferred embodiment, such as figure 2 As shown, the transmitting magnetic core 102 includes 3 layers of ferrite layers stacked staggeredly, which are respectively the first ferrite layer 43 corresponding to the periphery of the transmitting coil 101 and arranged close to the transmitting coil 101, and is indented from the first ferrite layer 43 The second ferrite layer 44 that is stacked and indented a...

Embodiment 2

[0050] Figure 4 It is a schematic diagram of the structure of a charging assembly for wireless charging of an electric vehicle according to an embodiment of the present invention. Including setting the above-mentioned transmitting assembly 10 and receiving assembly 20 in parallel, such as Figure 5 As shown, the receiving assembly 20 includes a metal casing 203 , a receiving magnetic core 202 , a receiving coil 201 and a non-metallic casing 203 installed sequentially from top to bottom.

[0051] As a further preferred embodiment, such as Image 6 As shown, the transmitting coil 101 or the receiving coil 201 is a hollow helical structure wound by at least two Litz wires 30 of equal length. Each Litz wire 30 is wound with the same number of coil turns, and each turn of Litz wire 30 has the same bending radius at the bending position 105 . The two ends of the first Litz wire 305 and the second Litz wire 306 are tangent at the transition point 307 radians, and the two adjacent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com