Motor, compressor and refrigeration equipment

A component and rotor core technology, applied in the field of refrigeration equipment, can solve the problem that the anti-demagnetization ability of the motor cannot meet the use requirements, and achieve the effects of high anti-demagnetization ability, stable operation, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

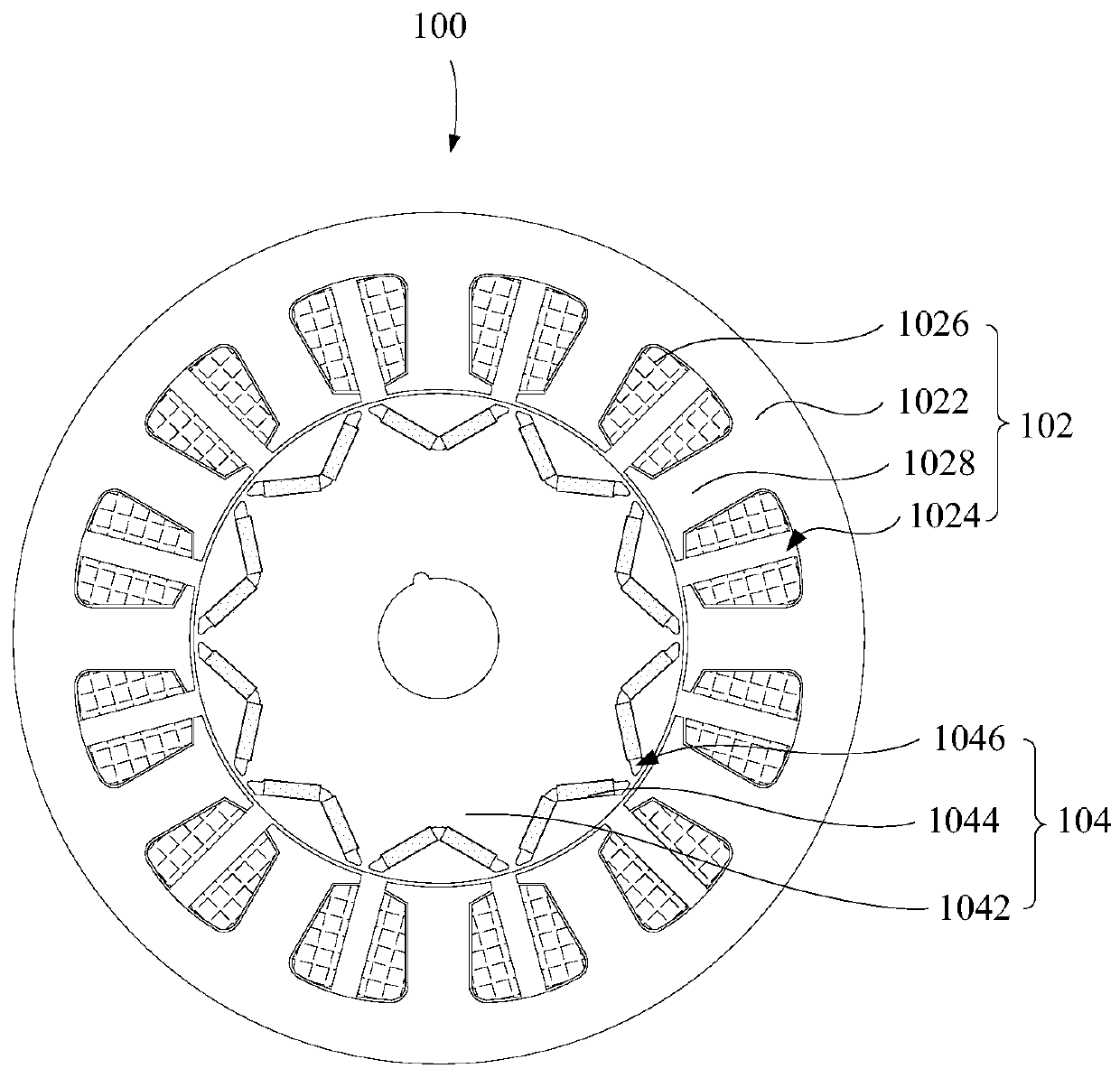

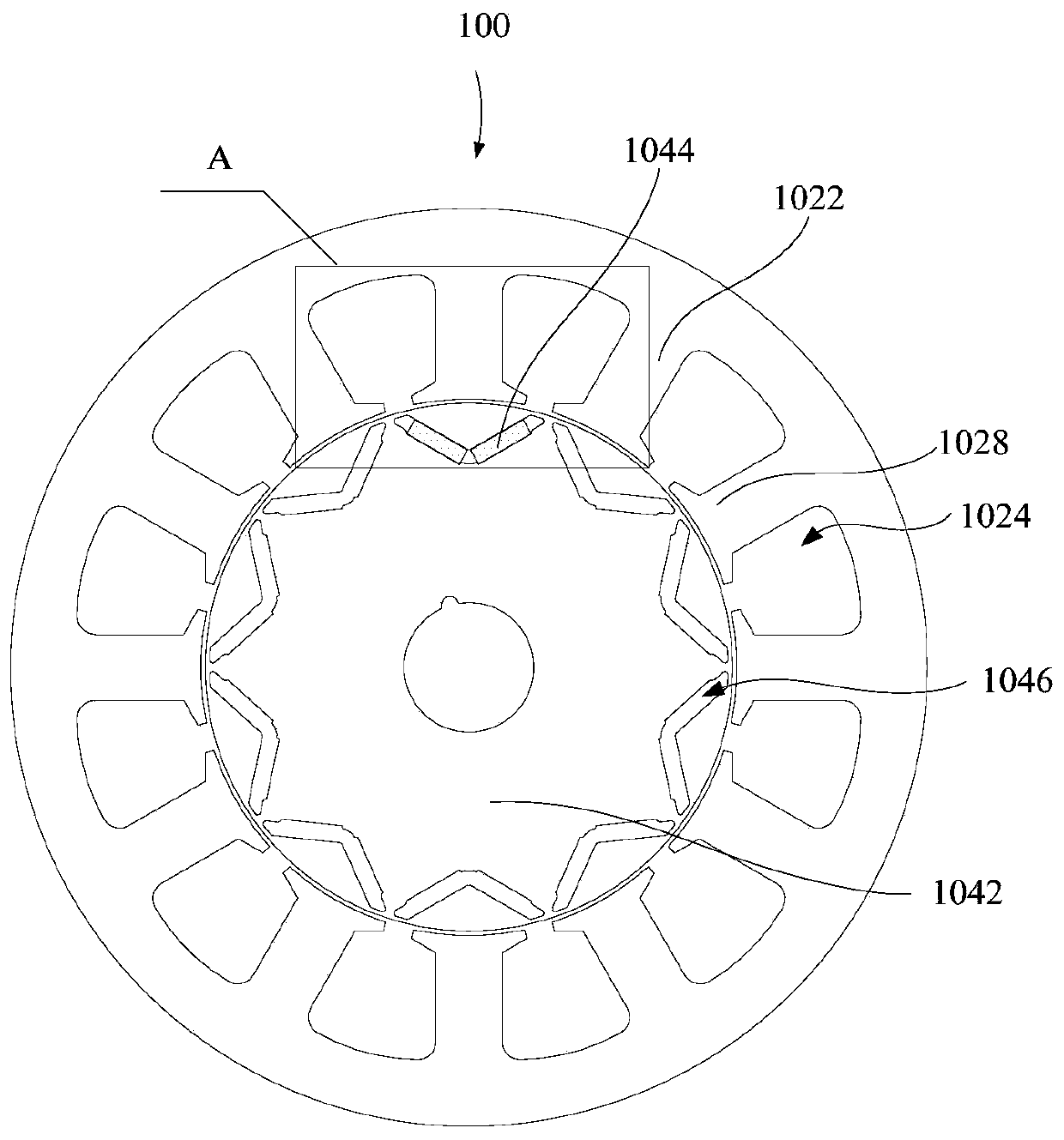

[0044] Such as Figure 1 to Figure 3 As shown, the first aspect of the present invention provides a motor 100, which includes a stator assembly 102 and a rotor assembly 104.

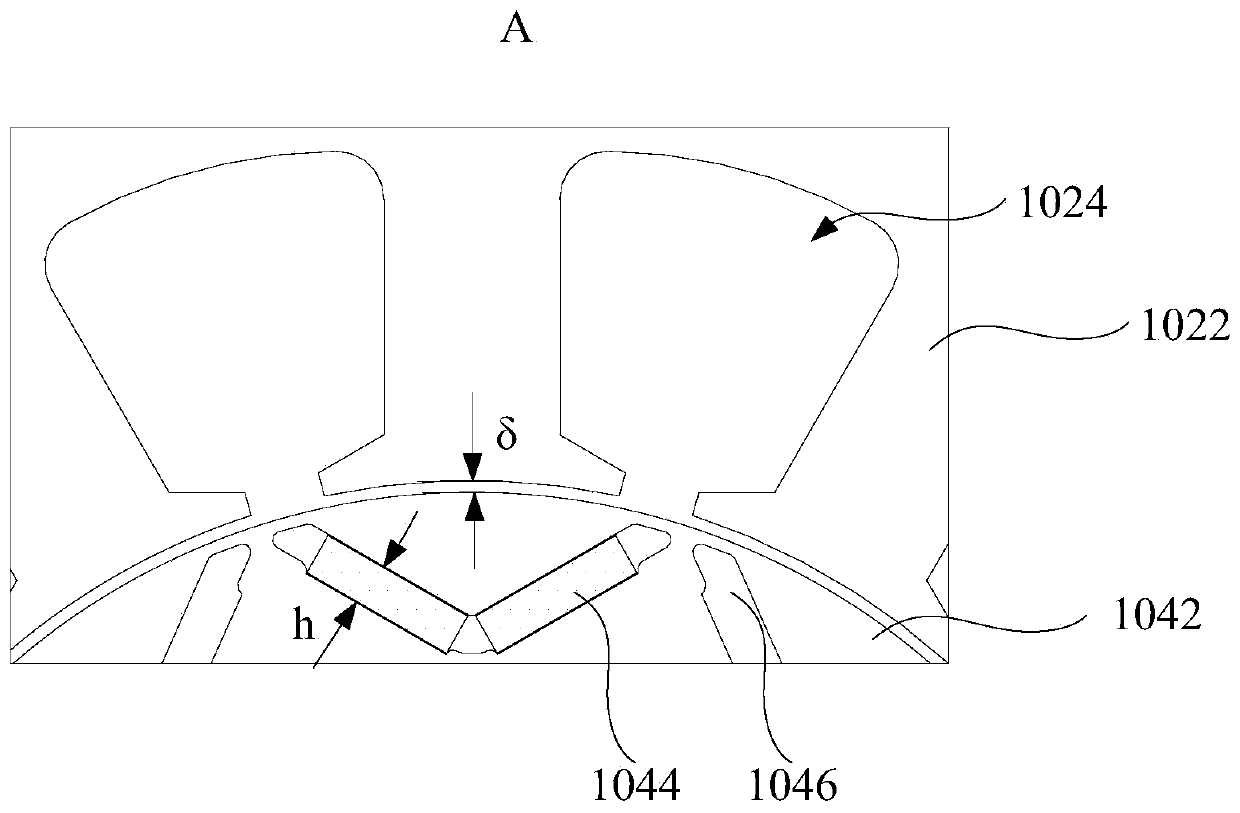

[0045] Specifically, such as figure 1 As shown, the stator assembly 102 includes a stator core 1022, the stator core 1022 is provided with a stator slot 1024, the rotor assembly 104 includes a rotor core 1042 and a permanent magnet 1044, and the rotor core 1042 is provided with a permanent magnet 1044, such as image 3 As shown, in a section perpendicular to the axis of the rotor core 1042, the distance between the stator core 1022 and the rotor core 1042 is defined as δ mm, the length of the permanent magnet 1044 in its own magnetization direction is h mm, and the stator slot The number of gaps 1024 is Q, the intrinsic coercivity of the permanent magnet 1044 is Hcj kA / m, and the Hcj is less than or equal to 1800 kA / m, and the distance between the stator core 1022 and the rotor core 1042 is further limited. ...

Embodiment 2

[0057] Such as Figure 1 to Figure 3 As shown, in an embodiment of the present invention, the motor 100 includes: a stator assembly 102 and a rotor assembly 104, wherein the stator assembly 102 includes a stator core 1022, the stator core 1022 is provided with a stator slot 1024; the rotor assembly 104, the rotor The assembly 104 includes a rotor core 1042 and a permanent magnet 1044; further, the number of stator slots 1024 is Q; the intrinsic coercivity of the permanent magnet 1044 is Hcj kA / m, and the Hcj is less than or equal to 1800 kA / m; the stator iron The distance between the core 1022 and the rotor core 1042 is δ mm; the length of the permanent magnet 1044 in its own magnetization direction is h mm; where the value of h satisfies: 80×(45-Q) / Hcj≤h≤1.3+ δ.

[0058] In this embodiment, as image 3 As shown, the numerical range of the length h mm of the permanent magnet 1044 in the magnetization direction of the permanent magnet 1044 is further limited as: 80×(45-Q) / Hcj≤h≤1....

Embodiment 3

[0065] Such as Figure 1 to Figure 3 As shown, in any of the above embodiments, further, the range of the mass percentage of dysprosium and / or terbium in the permanent magnet is: 0 to 0.5%, or the range of the mass percentage of heavy rare earth elements in the permanent magnet is: 0 to 0.5%.

[0066] In this embodiment, since dysprosium and terbium are heavy rare earth elements, which are national strategic resources, the mass percentage of heavy rare earth elements in the permanent magnet 1044 is positively correlated with the intrinsic coercivity Hcj of the permanent magnet 1044 . Therefore, on the one hand, by limiting the mass percentage of dysprosium and / or terbium in the permanent magnet 1044 to 0 to 0.5%, it is beneficial to reduce the use of dysprosium and / or terbium while ensuring the good demagnetization resistance of the motor 100 In turn, it is beneficial to reduce the manufacturing cost of the motor 100 and improve the cost performance of the motor 100. On the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com