One-dimensional iron-based wave-absorbing material derived from a metal organic framework, and preparation method thereof

A metal-organic framework and wave-absorbing material technology, which is applied in the direction of ferrous oxide, ferrous oxide, iron oxide/ferric hydroxide, etc., can solve the change of magnetic anisotropy and affect the complex permeability of wave-absorbing materials Spectrum and other issues, to achieve the effect of low production cost, excellent low-matching thickness broadband absorbing performance, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The specific preparation steps of a metal-organic framework-derived one-dimensional iron-based microwave-absorbing material are as follows:

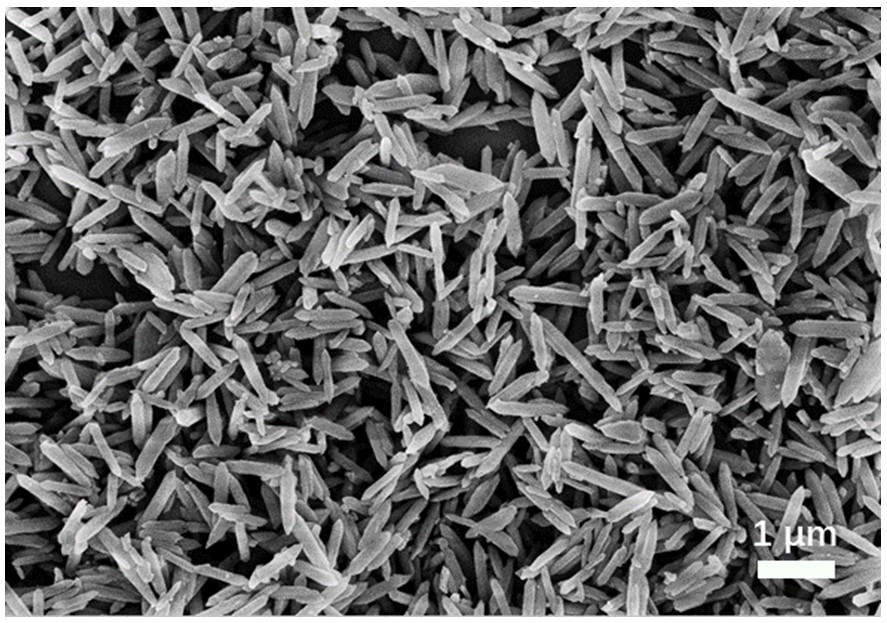

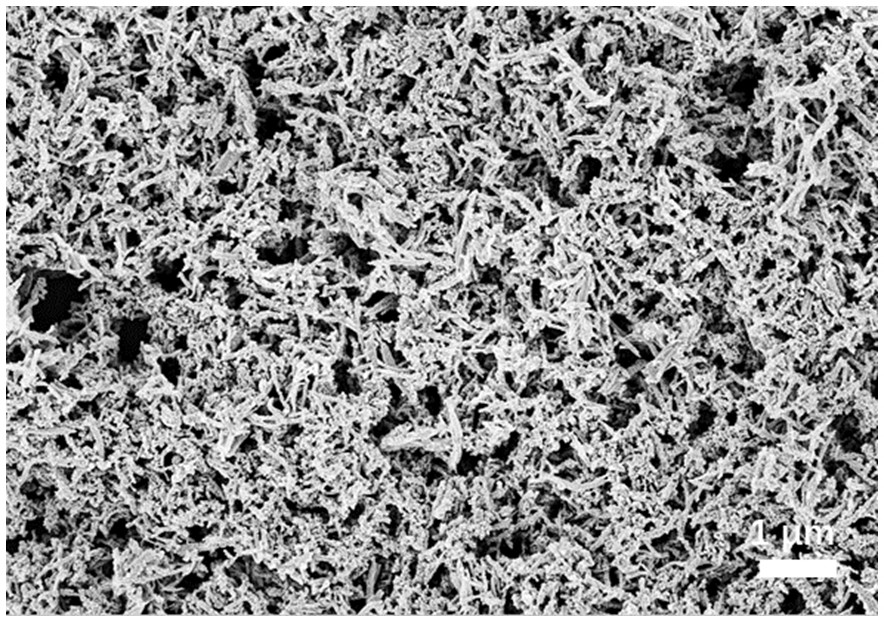

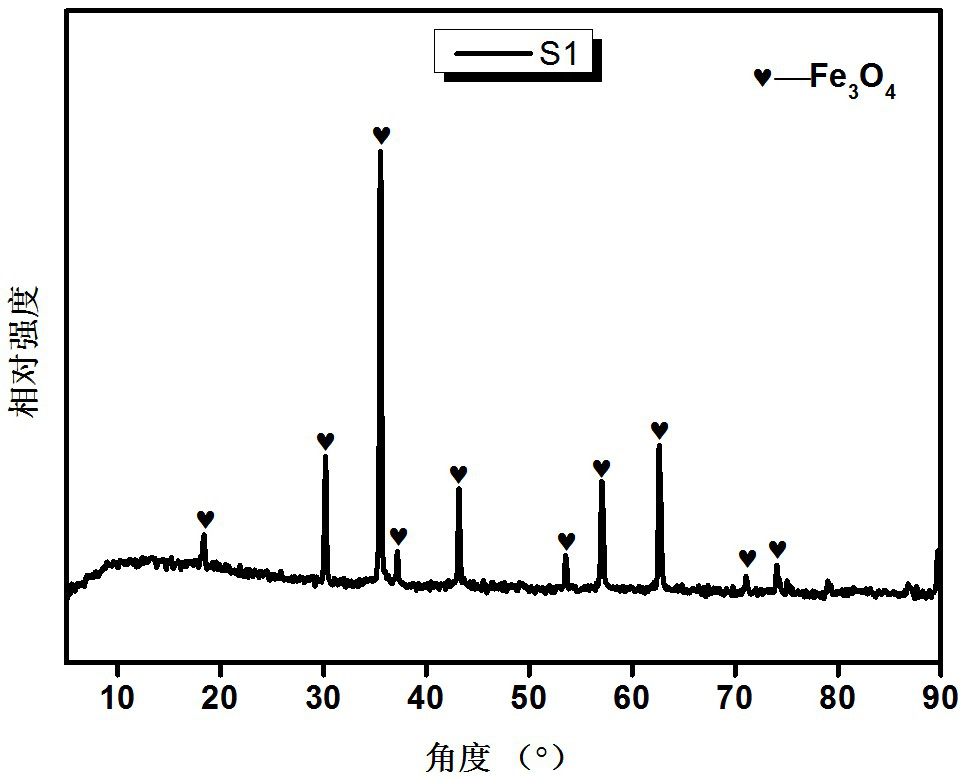

[0025] (1) Dissolve 1.08 g of ferric chloride hexahydrate in 54 mL of N,N-dimethylformamide solution, stir for 10 min, then add 0.88 g of terephthalic acid, and stir for 30 min to obtain an iron salt solution; Dissolve another 0.096 g of sodium hydroxide in 6 mL of deionized water, pour the sodium hydroxide solution into the iron salt solution, and conduct a solvothermal reaction at 100 °C for 24 h; after the reaction, centrifuge the product, and use N, N - washing with dimethylformamide twice, drying in a vacuum drying oven at a temperature of 80° C. for 1 hour; grinding to obtain a metal organic framework powder; the metal organic framework powder is light yellow, with iron as the central metal element, Using terephthalic acid as the organic ligand, denoted as Fe-bdc, the metal organic framework powder particles are in the shape...

Embodiment 2

[0035] The specific preparation steps of a metal-organic framework-derived one-dimensional iron-based microwave-absorbing material are as follows:

[0036] (1) Dissolve 1.08 g of ferric chloride hexahydrate in 54 mL of N,N-dimethylformamide solution, stir for 10 min, then add 0.88 g of terephthalic acid, and stir for 30 min to obtain an iron salt solution; Another 0.096 g of sodium hydroxide was dissolved in 6 mL of deionized water, the sodium hydroxide solution was added to the iron salt solution, and the solvothermal reaction was carried out at 100 °C for 24 h; Dimethylformamide was washed twice; dried in a vacuum drying oven at a temperature of 80° C. for 1 hour; ground to obtain a metal organic framework powder; the metal organic framework powder was light yellow, with iron as the central metal element, and Terephthalic acid is an organic ligand, which is denoted as Fe-bdc. The metal-organic framework powder particles are in the shape of one-dimensional rods with a rod len...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com