Method for preparing ferriferrous oxide microwave adsorbing material by utilizing copper-iron tailing pyrite cinder

A microwave absorbing material, the technology of ferric tetroxide, which is applied in ferrous oxides, chemical instruments and methods, iron oxide/iron hydroxide and other directions, can solve problems such as environmental pollution, and achieve high purity and strong magnetic properties. , the effect of high complex permittivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

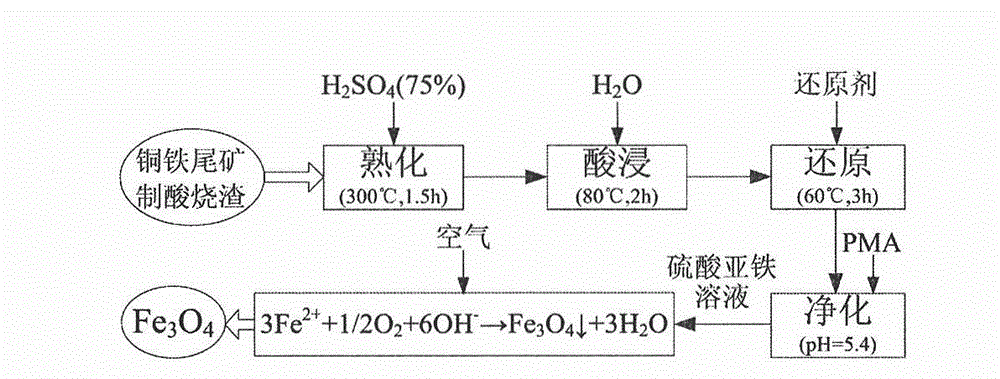

[0025] Step 1: Mix sulfuric acid with a volume concentration of 75% and acid-making slag from delafossite tailings at a liquid-solid ratio (ml / g) of 1.5:1. After the slag is solidified into gray particles, it is put into a muffle furnace and aged at 300°C for 2 hours. Transfer the matured slag into a three-necked bottle, add an appropriate amount of water (the liquid-solid ratio (ml / g) is 1.65:1), heat in a water bath and maintain 80°C, and stir at a rate of 400r / min. After 2h, filter to obtain crude ferric sulfate solution.

[0026] Step 2: Add water to the crude ferric sulfate solution to dilute to Fe 3+ The concentration is 1.1mol / L. After stirring and heating up to 90°C, add pyrite concentrate according to the ratio of solid-liquid ratio (g / ml) of 1:1.5, adjust the stirring rate to 200r / min, react for about 3 hours, and filter A crude ferrous sulfate solution was obtained.

[0027] Step 3: Add NaOH solution dropwise to the crude ferrous sulfate solution filtrate to adju...

Embodiment 2

[0031] Step 1: Same as Step 1 in Example 1, the aging temperature is adjusted to 180° C., and the aging time is 2.5 hours.

[0032] Step 2: Dilute crude ferric sulfate with water to Fe 3+ The concentration is 1.1mol / L, after stirring and heating up to 90°C, press Fe:Fe 3+ = 1.2:2 molar ratio to add iron filings, adjust the stirring rate to 200r / min, react for about 3h, and filter to obtain crude ferrous sulfate solution.

[0033] Step 3~step 4: with the step 3~step 4 in the embodiment 1, make Fe 3 o 4 magnetic particles.

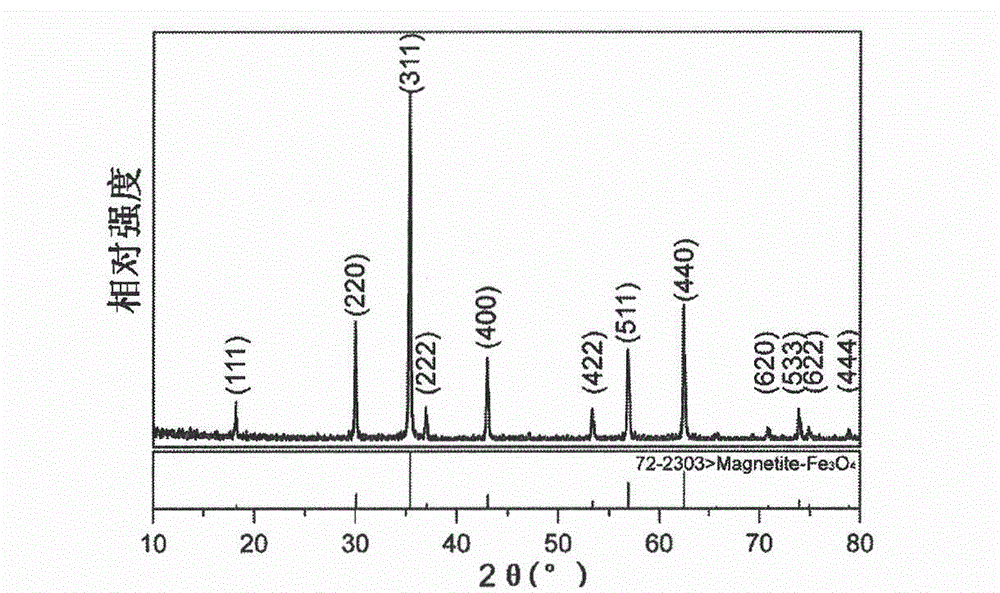

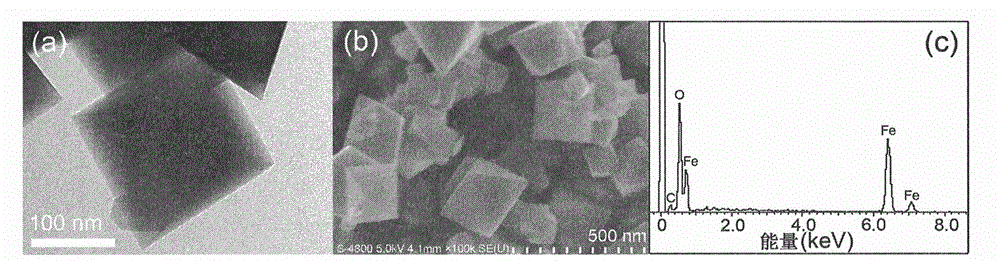

[0034] image 3 (a), (b) and (c) are the Fe that embodiment 2 makes respectively 3 o 4 Transmission electron microscope (JEM-100CX11 transmission electron microscope of JEOL Ltd.), scanning electron microscope and EDS elemental analysis diagram of magnetic particles (S-4800 cold field emission scanning electron microscope of Hitachi Electronics Co., Ltd.). image 3 (a) clearly shows that Fe 3 o 4 The magnetic particle size is about 200nm, from ima...

Embodiment 3

[0036] Step 1-Step 2: Same as Step 1-Step 2 in Example 1, the aging temperature was adjusted to 110° C., and the aging time was 3 hours to prepare a crude ferrous sulfate solution.

[0037] Step 3: Add sodium hydroxide dropwise to the crude ferrous sulfate solution to adjust the pH value to 5.5, and then add a small amount of polyacrylamide for flocculation and precipitation after filtration. After the precipitation is complete, filter to obtain a pure ferrous sulfate solution.

[0038] Step 4: with the step 4 in the embodiment 1, make Fe 3 o 4 magnetic particles.

[0039] Use the Nanjing University HH-50 hysteresis loop measuring instrument to measure and draw the Fe obtained in embodiment 3 at 300K 3 o 4 The hysteresis loop, such as Figure 4 Shown, the saturation magnetization of ferromagnets (M s ), residual magnetization (M r ) and coercivity (H c ) are 28.1, 3.0emu / g and 241.3Oe, respectively, with strong magnetic properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com