High-frequency soft magnetic material, composite material and preparation method

A technology of magnetic composite materials and soft magnetic materials, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of high-frequency soft magnetic performance reduction, unfavorable high complex permeability, narrow frequency band, etc., and achieve improved resonance Effect of Frequency, High Permeability, Wide Resonance Frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following are examples of the present invention.

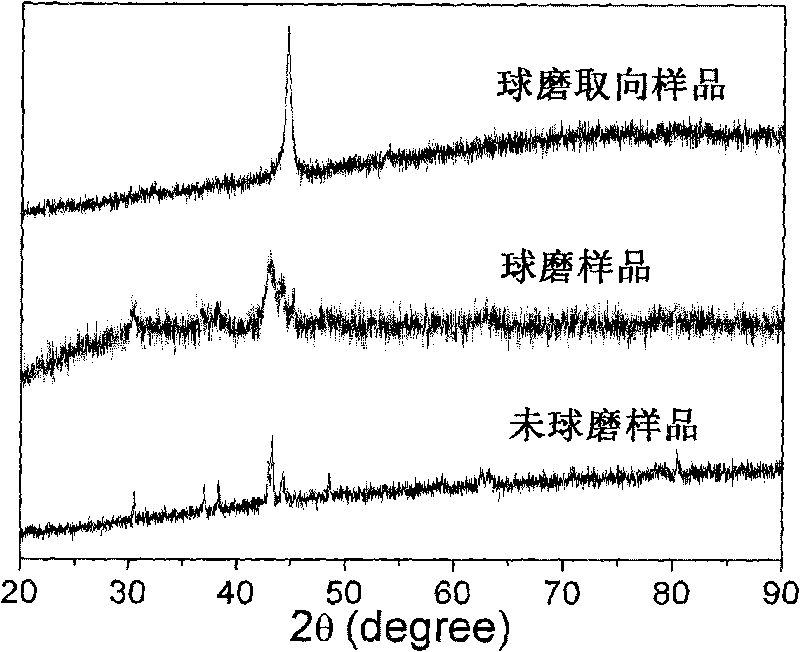

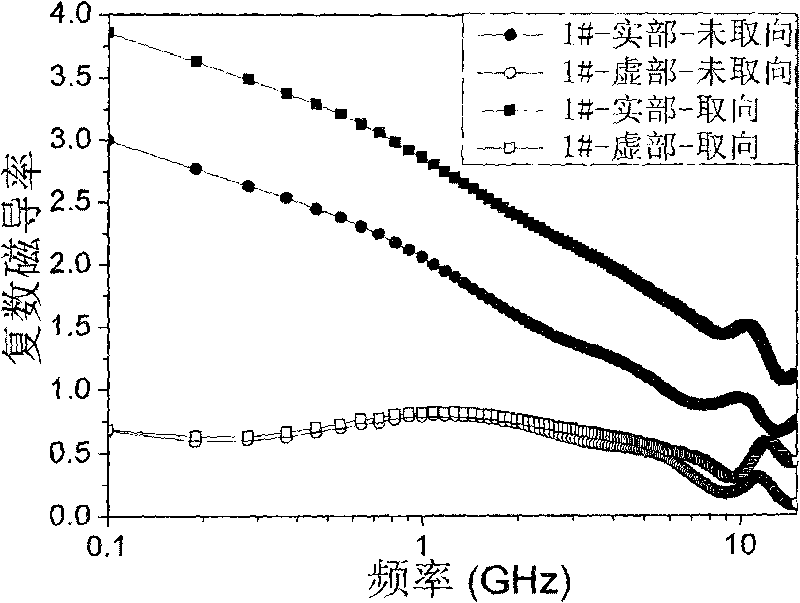

[0013] Weigh 2.330g of neodymium, 6.473g of cobalt and 1.534g of iron, and melt them into ingots under the protection of argon. Placed in a vacuum quartz tube for homogenization heat treatment at 1000°C for one week. The homogenized heat-treated ingot is ground into particles of about 10-100 microns with an agate mortar. The grinding process is carried out under the protection of n-hexane liquid. The purpose of using n-hexane is to prevent oxidation, and its addition can cover The sample is enough, and the obtained material is measured in the X'Pert PRO diffractometer of Philips Company, and the results obtained by measuring its crystal structure are shown in figure 1 . Then add 60ml of n-hexane into the planetary ball mill to make the powder less than or equal to 5 microns, the mass ratio of ball and material during ball milling is 10:1, the ball milling speed is 200r / min, the ball milling time is set to 16h, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com