Electromagnetic coating of high-performance cooker and manufacturing method of electromagnetic coating

A technology for coating and cookware, applied in coating, metal material coating process, heating inorganic powder coating, etc., can solve the problems of unsatisfactory pure iron coating and easy rust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

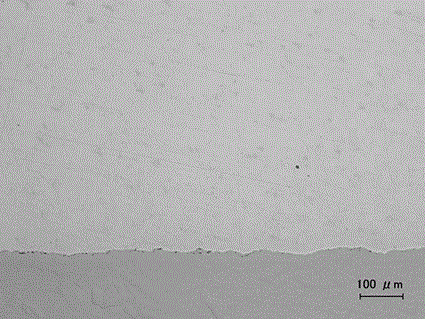

Image

Examples

Embodiment 1

[0029] Embodiment 1: Prepare the mixed electromagnetic coating of 430 stainless steel and nickel in the electric cooker liner of 304 stainless steel material and the electric cooker liner of aluminum material

[0030] Spray on the bottom of the rice cooker liner made of 304 stainless steel. The spray material is a mixture of 430 stainless steel and nickel. The powder particle size ranges from 100 to 500 mesh. Put the rice cooker liner in the tooling and fix it on the rotating platform , the distance between the tooling plane and the surface of the pot is 5mm, the spraying trajectory covers the bottom of the pot, the spraying gas is nitrogen, the gas pressure is adjusted to 4.0MPa, the spray gun temperature is set at 650°C, and the coating thickness is set at 0.2-0.3mm. After the parameters are set, start spraying.

[0031] After the spraying is completed, the inner pot of the electric rice cooker is heated on the induction cooker to detect the actual power utilization rate. Th...

Embodiment 2

[0032] Embodiment 2: Prepare the mixed electromagnetic coating of 430 stainless steel and nickel in the electric cooker liner of 304 stainless steel material and the electric rice cooker liner of aluminum material

[0033] Spray on the bottom of the rice cooker liner made of 304 stainless steel. The spray material is a mixture of 430 stainless steel and nickel. The powder particle size ranges from 100 to 500 mesh. Put the rice cooker liner in the tooling and fix it on the rotating platform , the distance between the tooling plane and the surface of the pot is 5mm, the spraying trajectory covers the bottom of the pot, the spraying gas is nitrogen, the gas pressure is adjusted to 4.0MPa, the spray gun temperature is set at 650°C, and the coating thickness is set at 0.4-0.5mm. After the parameters are set, start spraying.

[0034] After the spraying is completed, the inner pot of the electric rice cooker is heated on the induction cooker to detect the actual power utilization rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com