Absorber for radio-frequency identificating antenna and radio-frequency identificating antenna using the same

A manufacturing method and magnetic sheet technology, applied in the field of RFID antennas, can solve the problems of non-featured and too thick magnetic sheet RFID antennas, etc., and achieve the effects of noise attenuation, high yield, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and Embodiment 2

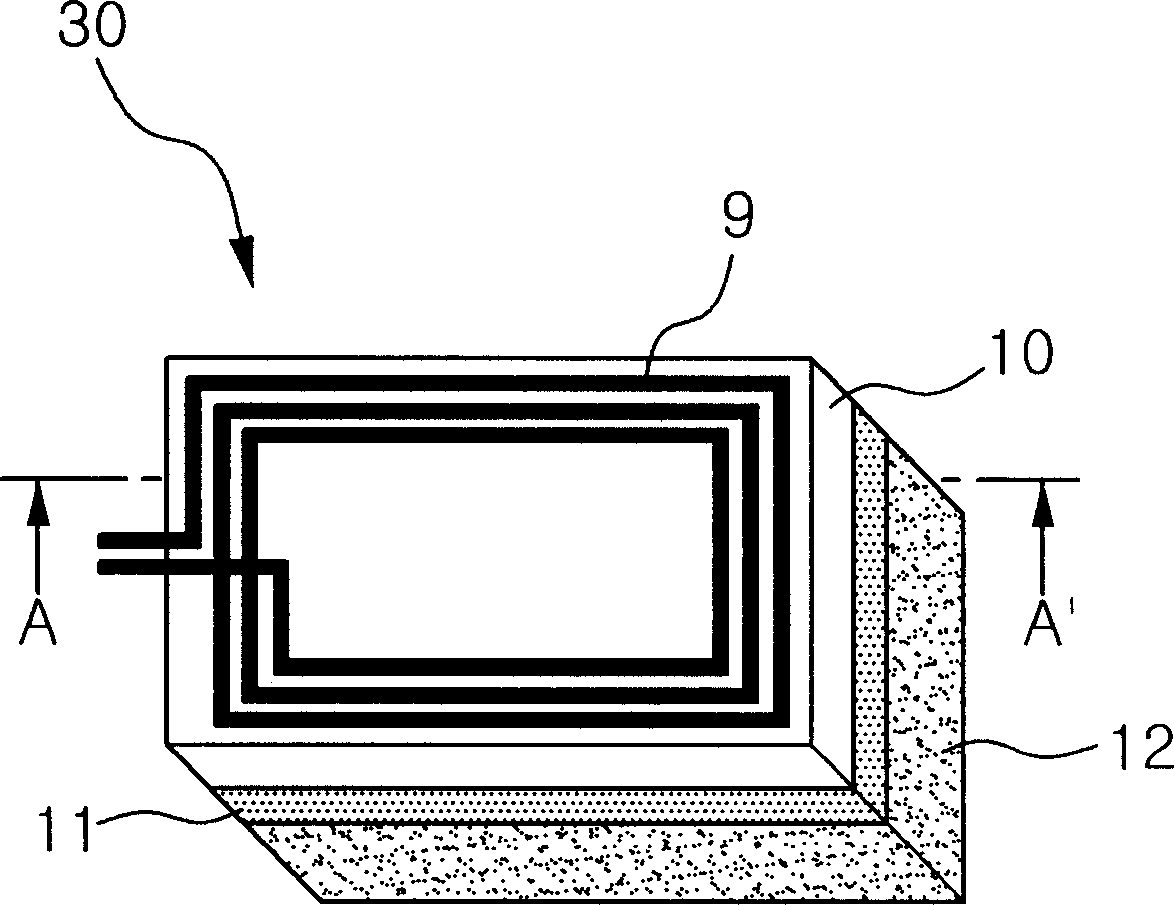

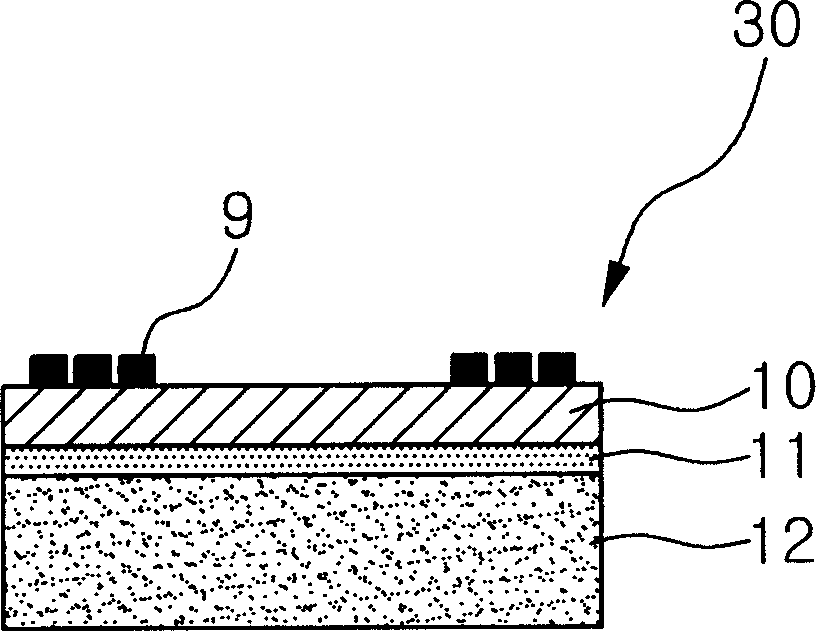

[0118] In order to obtain the same structure as in Example 1 in FIG. 2A , a copper antenna coil was formed on a 0.20 mm thick polyimide insulating layer by etching the copper antenna coil to a 10z specification (ie, a coil thickness of 0.04 mm).

[0119] On the other hand, an amorphous alloy Fe-Si-B is made to form a magnetic sheet used as an absorbing sheet. The starting material Fe-B can be used as a master alloy. Electrolytic iron Fe and Si are mixed with the starting material Fe-B to adjust the composition ratio, and then melted together in a furnace to make Fe 79 (Si, B) 21 ingot iron. After the ingot iron is produced in the high-frequency induction furnace, the high-frequency induction furnace is switched on to apply high-frequency energy to the ingot iron, so that the ingot iron is completely melted. After that, the molten metal at high temperature was sprayed on a cooling roll rotating at a high speed through nozzles, thereby forming an amorphous alloy ribbon with a...

Embodiment 3 and Embodiment 4

[0123] FINEMET (registered trademark) of Hitachi Corporation of Japan or Fe of Vitroperm (registered trademark) of Vacuumschmelze Company of Germany 73.5 Cu 1 Nb 3 Si 13.5 B 9 Compositions can be used as alloys for the magnetic sheets of Example 3 and Example 4. The fabrication method of the RFID was the same as in Example 1, except that the magnetic sheet was made 0.20 mm thick (Example 3) or 0.25 mm thick (Example 4).

Embodiment 5

[0125] Fe-B can be used as a starting material for an alloy for forming a magnetic sheet. In order to adjust the composition ratio, electrolytic iron (Fe) and Zr are added to prepare 90 Zr 7 B 3 composed of amorphous alloys. The fabrication method of the RFID antenna is the same as in Embodiment 1 except that the magnetic sheet is made 0.25 mm thick.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com