Ni/TiO2-based electromagnetic rheological liquid with electromagnetic coupling effect and preparation method thereof

An electromagnetic coupling, rheological fluid technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of large proportion of metal core-shell dispersed phase particles, poor anti-settling resistance of electro-rheological fluid, low electro-rheological strength, etc., to improve electrical conductivity. , The effect of improving shear strength and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] a) Preparation of base liquid

[0040] Mix fluorinated silicone oil (70v%) and simethicone oil (30v%) evenly to obtain compound base fluid;

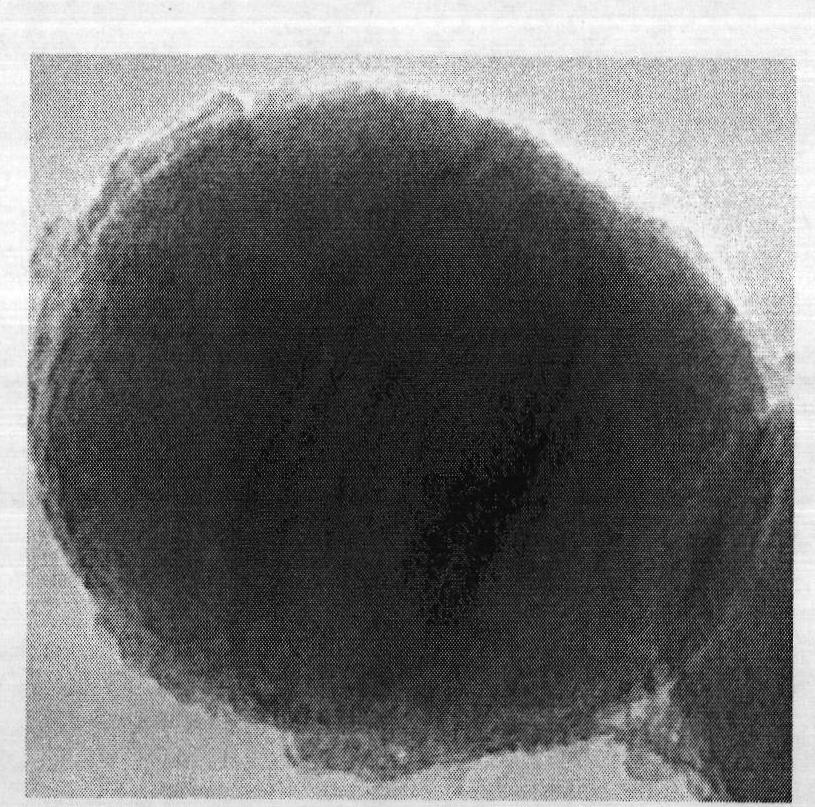

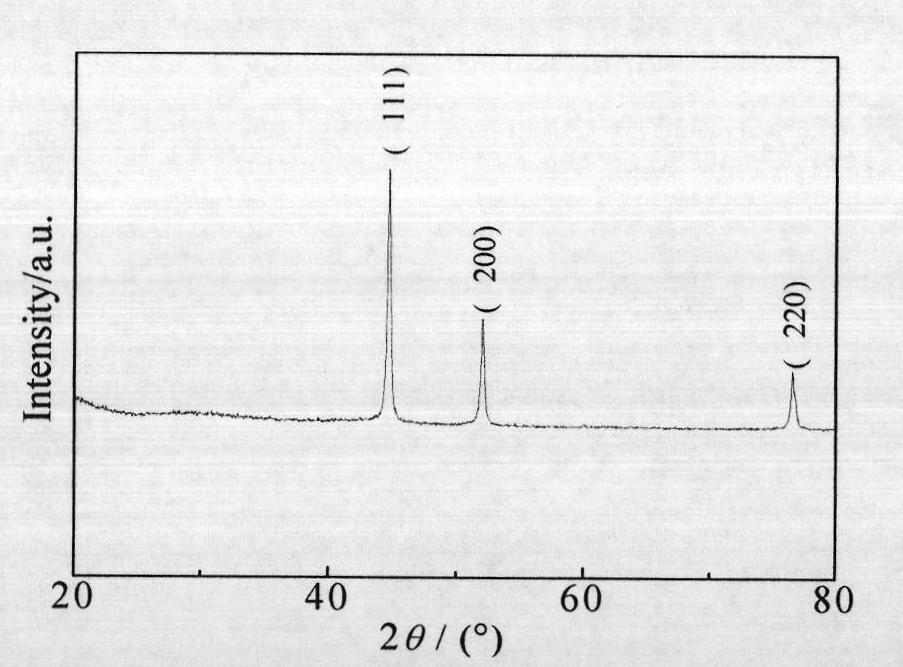

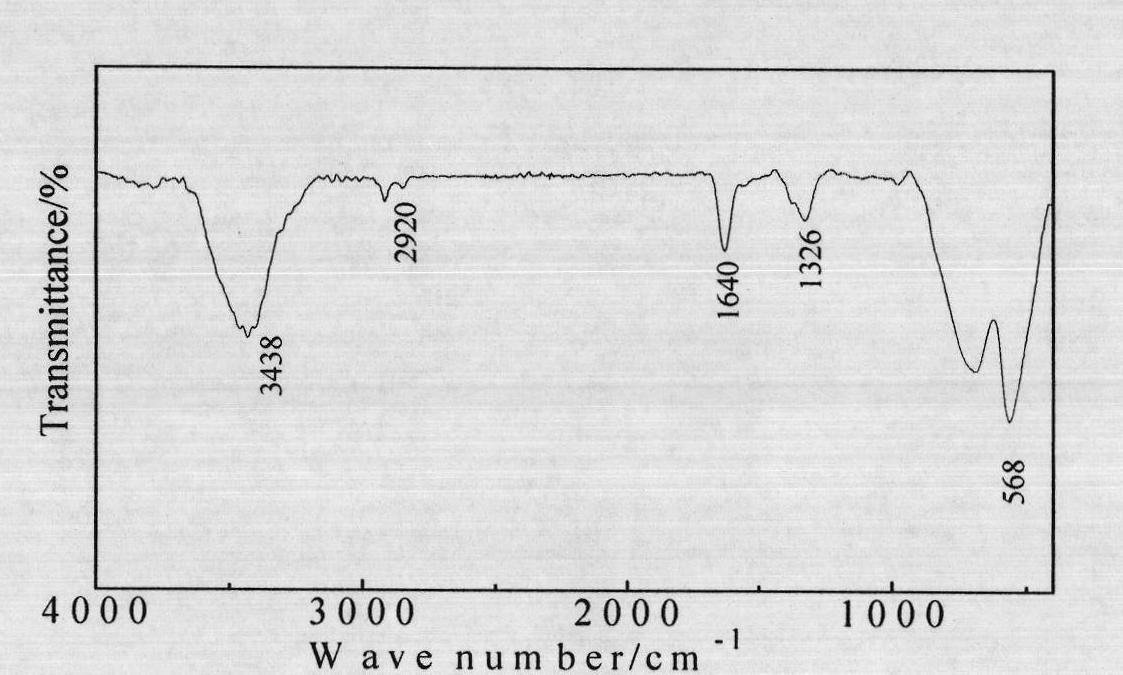

[0041] b) Nano-nickel powder prepared by spray deposition method (TEM image as shown in figure 1 As shown, the XRD pattern is as figure 2 As shown, the infrared spectrum FT-IR is shown as image 3 shown) into a NaOH solution with a concentration of 6 mol / L, and uniformly stirred to hydroxylate the surface of Ni particles; after dispersion treatment, and then washed with deionized water until neutral, the precipitate was separated to obtain particle A;

[0042] c) adding an ethanol solution of barium titanate with a volume ratio of 1:1 to microparticles A, wherein the molar ratio of microparticles A to barium titanate is 4:1, vigorously stirring for sol-gel reaction, resulting in precipitation, and Particle B was obtained by precipitation and separation; after drying the particle B, the first layer of coated TiO was generated ...

Embodiment 2

[0047] a) Preparation of base liquid

[0048] Mix fluorinated silicone oil (30v%) and dimethicone oil (70v%) evenly to obtain compound base fluid;

[0049] b) adding the nano-nickel and NaOH solution into the NaOH solution with a concentration of 8mol / L in a ratio of 1:45 by weight and stirring evenly; stirring until the reaction is complete to obtain precipitation, and separating the precipitation to obtain particle A;

[0050] c) adding an ethanol-tetrabutyl titanate solution with a volume ratio of 1:1.25 to the microparticles A, wherein the molar ratio of the microparticles A to tetrabutyl titanate is 6:1, stirring evenly, separating and precipitating to obtain the microparticles B;

[0051] c) Add the ethanol mixed solution containing deionized water, urea and SDBS to microparticles B, wherein the volume ratio of deionized water: urea and SDBS: absolute ethanol is 1:4:10, and the volume ratio of urea, SDBS and microparticles B The weight ratio is 1:4, stir evenly until th...

Embodiment 3

[0054] a) Preparation of base liquid

[0055] Mix fluorinated silicone oil (40v%) and simethicone oil (60v%) evenly to obtain compound base fluid;

[0056] b) adding the nano-nickel and NaOH solution prepared by the electrochemical method into the NaOH solution with a concentration of 8mol / L in a weight ratio of 1:45 and stirring evenly; stirring until the reaction is complete to obtain precipitation, and separating the precipitation to obtain particle A;

[0057] c) adding an ethanol-tetrabutyl titanate solution with a volume ratio of 1:1.25 to the microparticles A, wherein the molar ratio of the microparticles A to tetrabutyl titanate is 6:1, stirring evenly, separating and precipitating to obtain the microparticles B;

[0058] c) Add an ethanol mixed solution containing deionized water and urea to microparticles B, wherein the volume ratio of deionized water: SDBS: absolute ethanol is 1:2:15, and the weight ratio of SDBS to microparticles B is 1:8 , stir evenly until the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com