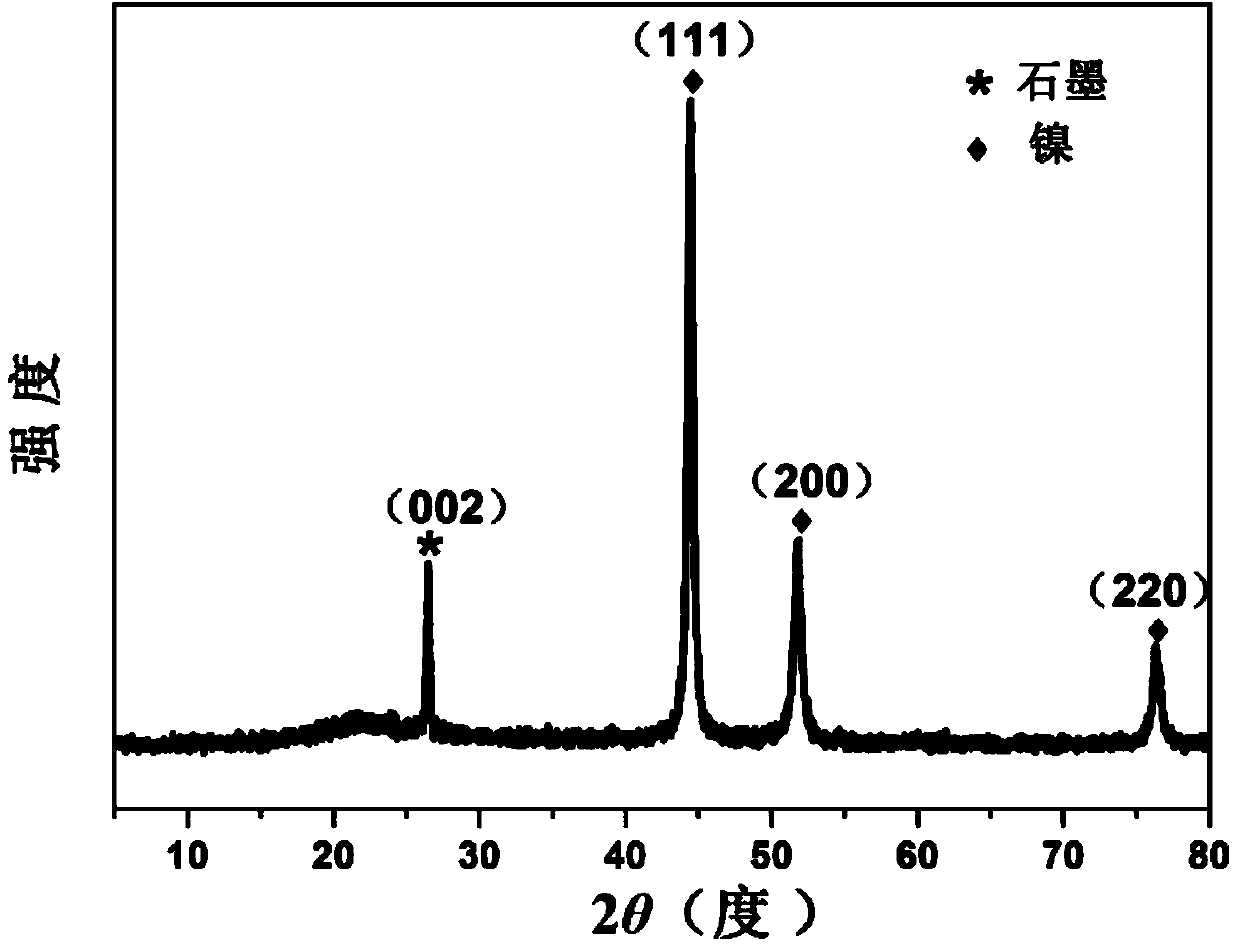

Nickel-coated graphite composite particle preparation method

A technology of composite particles and nickel-coated graphite, which is applied in the direction of liquid chemical plating, coating, metal material coating technology, etc., can solve the problems of poor electrical conductivity of composite particles, reducing the size of graphite powder, and unsatisfactory coating effect, etc. , to achieve the effect of uniform nickel shell, high utilization rate, and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] With 100mL of absolute ethanol and 100mL of deionized water as the solvent, add 10g of flake graphite particles into a 250mL Soxhlet extractor at 85°C, reflux for 8 hours; filter and vacuum dry for later use. Put the cleaned and dried graphite particles into 200g / L nickel sulfate solution for adsorption for 12h, filter and dry for later use; then take 0.5g of the above-mentioned graphite particles and place them in ethanol solution of sodium borohydride (12.5g / L) for 4h, After the graphite particles and ethanol solution are separated, filter, wash and dry for later use. To prepare the electroless nickel plating solution, take 5g of nickel sulfate hexahydrate, 7.5g of sodium citrate, 5g of ammonium chloride, 10mL of ammonia water, and 2mL of 85% hydrazine hydrate solution to prepare a 250mL electroless nickel plating solution; put 250mL of the electroless nickel plating solution into Heat the three-necked flask to 90°C, add 0.5 g of pre-treated graphite particles, and re...

Embodiment 2

[0038]With 133mL of absolute ethanol and 67mL of deionized water as the solvent, add 10g of flake graphite particles into a 250mL three-necked flask and reflux for 8 hours; filter and vacuum dry for later use. Put the cleaned and dried graphite particles into 200g / L nickel sulfate solution for adsorption for 12h, filter and dry for later use; then take 0.5g of the above-mentioned graphite particles and place them in ethanol solution of sodium borohydride (12.5g / L) for 4h, After the graphite particles and the ethanol solution were separated, they were filtered and dried for later use. To prepare the electroless nickel plating solution, take 5g of nickel sulfate hexahydrate, 7.5g of sodium citrate, 5g of ammonium chloride, 10mL of ammonia water, and 2mL of 85% hydrazine hydrate solution to prepare a 250mL electroless nickel plating solution; put 250mL of the electroless plating solution into three ports Heat the flask to 83° C., add 0.5 g of pre-treated graphite particles, and r...

Embodiment 3

[0041] With 167mL of absolute ethanol and 33mL of deionized water as the solvent, add 10g of flake graphite particles into a 250mL Soxhlet extractor at 85°C and reflux for 8 hours; filter and vacuum dry for later use. Put the cleaned and dried graphite particles into 200g / L nickel sulfate solution for adsorption for 12h, filter and dry for later use; then take 0.5g of the above-mentioned graphite particles and place them in ethanol solution of sodium borohydride (12.5g / L) for 4h, After the graphite particles and the ethanol solution were separated, they were filtered and dried for later use. To prepare the electroless nickel plating solution, take 5g of nickel sulfate hexahydrate, 7.5g of sodium citrate, 5g of ammonium chloride, 10mL of ammonia water, and 2mL of 85% hydrazine hydrate solution to prepare a 250mL electroless nickel plating solution; put 250mL of the electroless plating solution into three ports Heat the flask to 81° C., add 0.5 g of pre-treated graphite particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com