Coil component

A technology of coil components and coils, applied in coil manufacturing, electrical components, transformer/inductor coils/windings/connections, etc., can solve the flexural deformation of the bottom plate, high core body brittleness, bending resistance, weak impact resistance, etc. problem, to achieve the effect of increasing the inductance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] In the production of the inductor 10 of the present embodiment, first, the anisotropic composite magnetic sheets 20a, 20b produced by any of the methods described above are prepared.

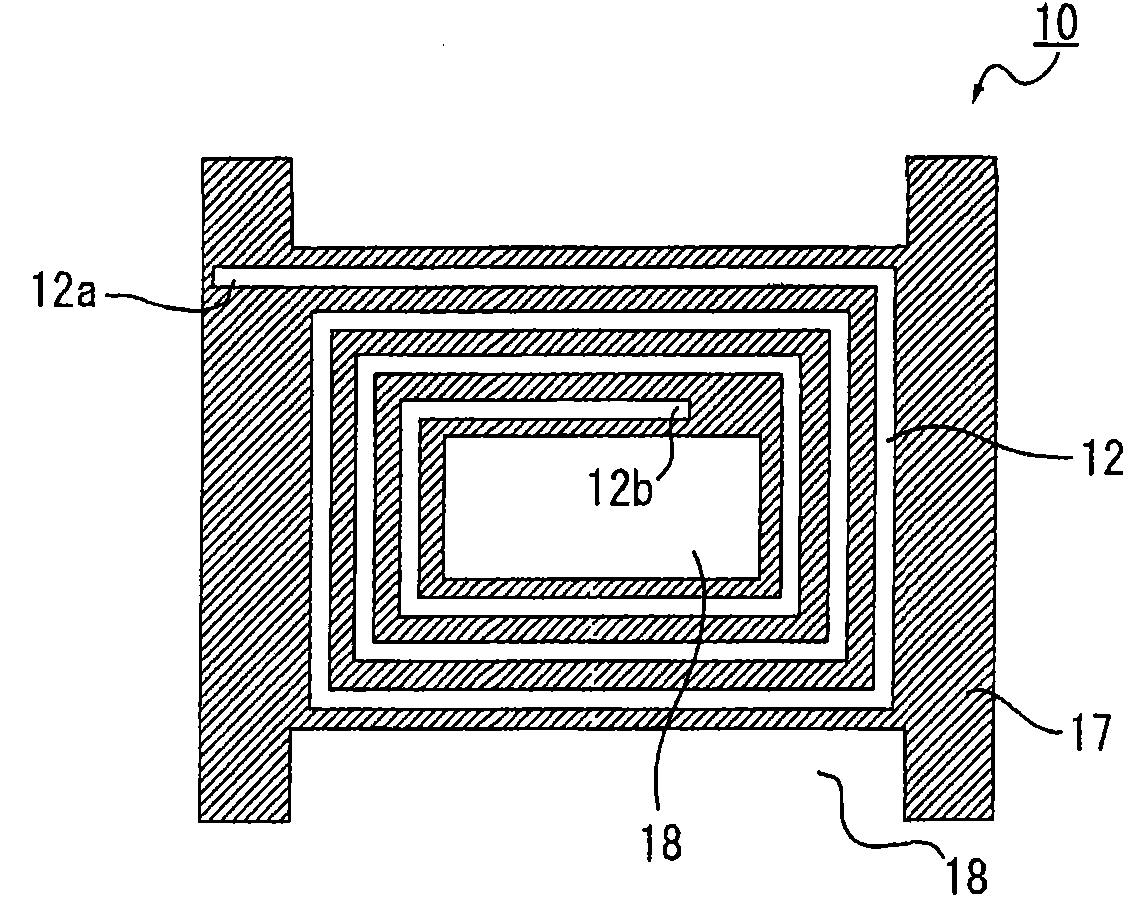

[0089] Next, the base film 17 ( Figure 2C ).

[0090] Composite magnetic material 32 ( Figure 3D ).

[0091] Another anisotropic composite magnetic sheet 20 (20a) is placed on the air-core coil 12, and they are hot-pressed to make them thermally melt into one body ( Figure 3E ).

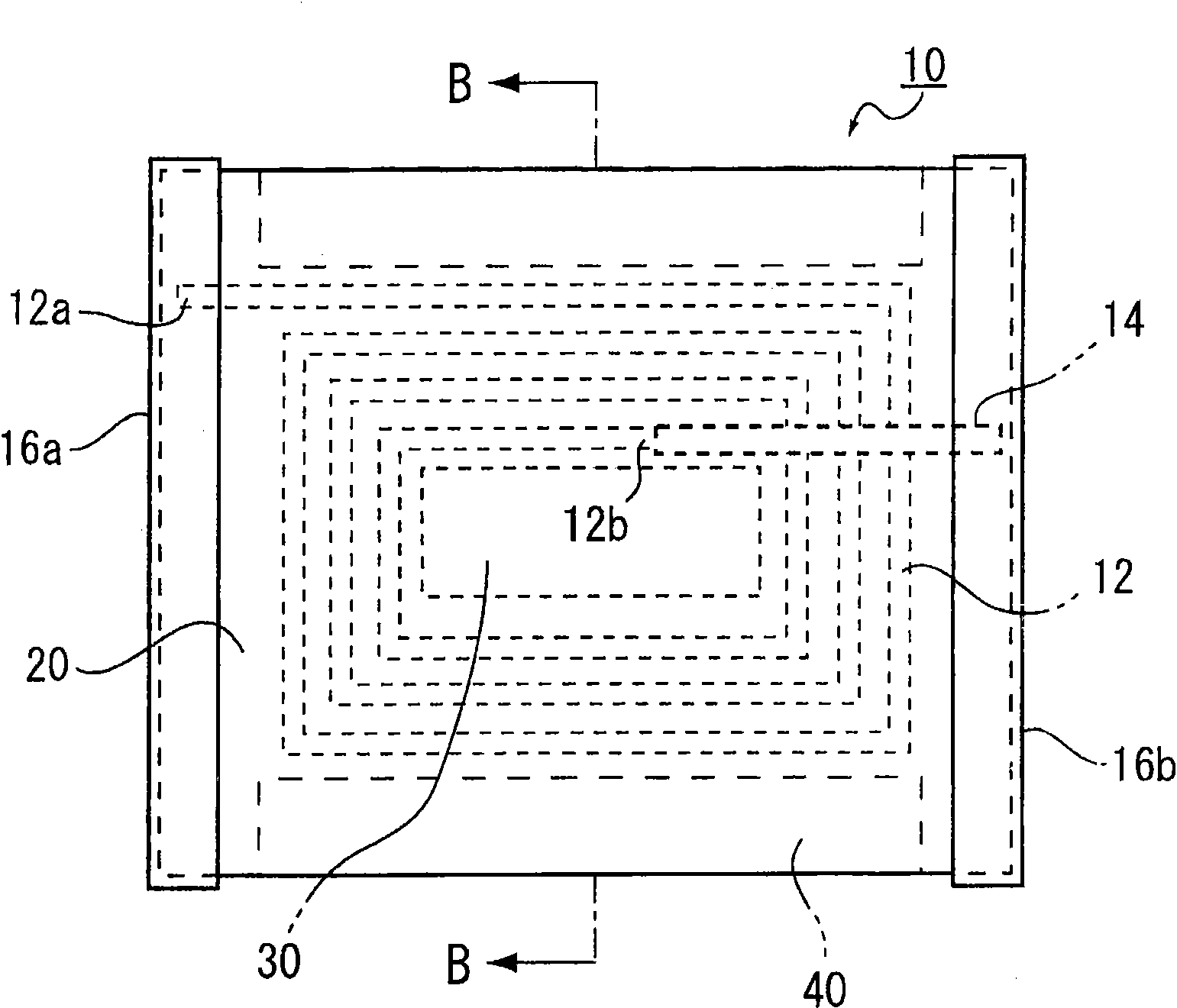

[0092] External electrodes 16a, 16b are installed on the base film 17 exposing the anisotropic composite magnetic sheet 20a, and the outermost end 12a of the air-core coil 12 and the conductor 14 joined to the innermost end 12b of the air-core coil 12 are respectively connected to the outer electrodes 16a and 16b. The electrodes 16a, 16b are electrically connected, whereby the inductor 10 is prepared.

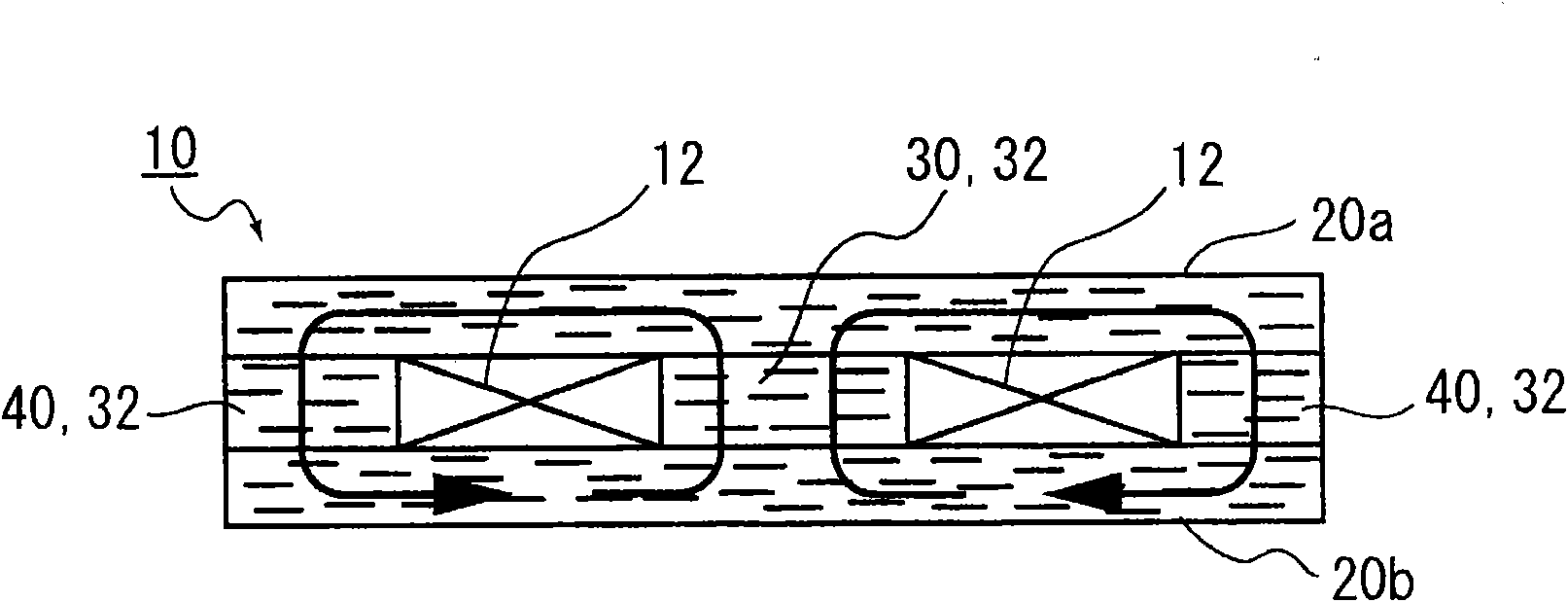

[0093] The anisotropic metal powder dispersed in the anisotropic composite magnetic sheet 20 is more p...

Embodiment

[0120] about Figure 1B A first embodiment showing a cross-sectional view, with Figure 4A A second embodiment showing a cross-sectional view, with Figure 4B A third embodiment showing a cross-sectional view, with Figure 4C A fourth embodiment showing cross-sectional views, with Figure 5C The inductor 10 in the seventh embodiment showing a sectional view, the inductance value [μH] and the DC superposition characteristic [A] were respectively simulated. As a comparative example, such as Figure 7 In the cross-sectional view shown in , the inductance value and DC superposition characteristics are similarly simulated for the inductor 11 in which isotropic metal powder is dispersed in the composite magnetic sheet 21 laminated on the upper and lower surfaces of the air-core coil 12 , and then both the core part 30 and the peripheral part 40 are filled with an isotropic composite magnetic material 35 .

[0121] For the anisotropic composite magnetic sheet 20 and the anisotro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com